классификация: СЕРИЯ КЕТ

Страна: Тайвань

Телефон: 886-2-2281-3361

факс: 886-2-2281-8206

Контактное лицо: Terry Hsieh

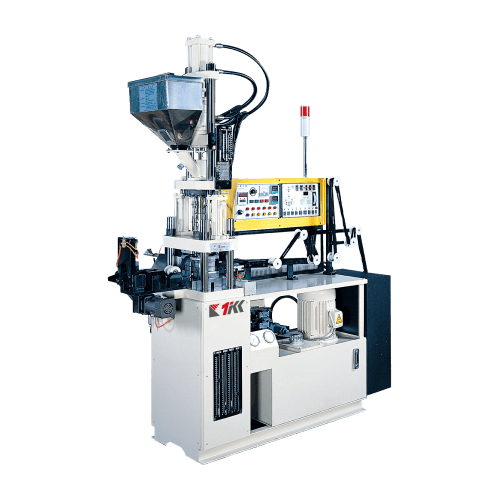

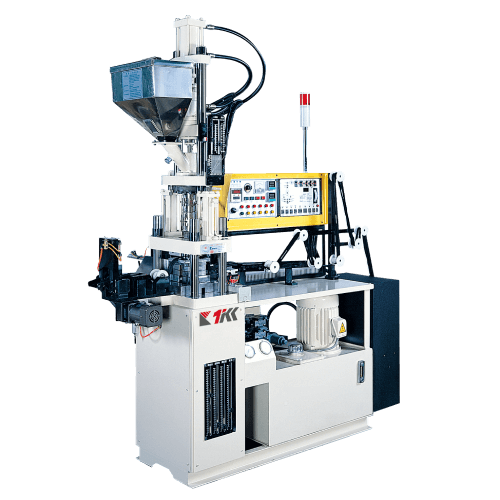

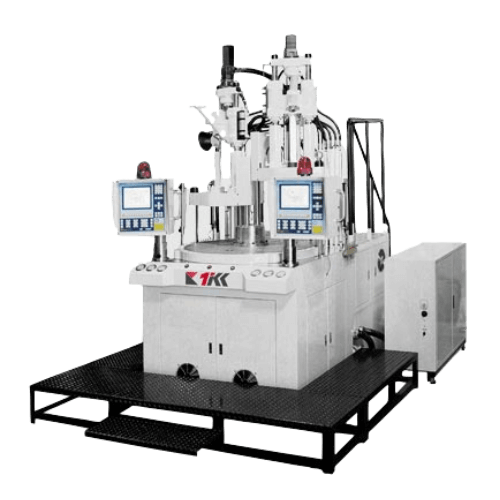

At Taiwan Kinki Machinery, we are proud to introduce our cutting-edge All-Electric Injection Molding Machine with Rotary Table, designed specifically to meet the growing demand for efficient and high-quality automotive parts molding. With its advanced features and superior performance, this state-of-the-art machine is poised to revolutionize the industry.

- High Efficacy for Increased Productivity: Efficiency is at the core of our All-Electric Injection Molding Machine. By harnessing the power of advanced servo motor technology, we have achieved exceptional energy efficiency and rapid response times, resulting in heightened productivity. With precise control and fast cycle times, you can optimize your production output while maintaining the highest standards of quality.

- Rotary Table for Enhanced Versatility: Our All-Electric Injection Molding Machine comes equipped with a revolutionary Rotary Table, providing unparalleled versatility in automotive parts molding and beyond. The Rotary Table allows for precise and simultaneous multi-component molding, ensuring superior product quality and consistency. With this innovative feature, you can now achieve complex geometries, multi-material combinations, and intricate designs with ease.

- Low Noise: One of the standout advantages of our All-Electric Injection Molding Machine is its remarkably low noise level during operation. By utilizing cutting-edge technology and intelligent design, we have successfully reduced noise emissions to create a quieter production environment. This not only enhances the comfort and well-being of your operators but also contributes to a more sustainable and harmonious workplace.

- Saving Water: All-electric injection molding machines eliminate hydraulic systems in hydraulic injection molding machines that use hydraulic oil to power their operations. This oil needs to be cooled to prevent overheating, which is typically done using water. In all-electric machines, the hydraulic system is eliminated, removing the need for water cooling.

- Saving Power: All-electric machines utilize electric servo motors for each machine function, such as the injection, clamping, and ejection processes. These motors only consume electricity when actively performing a task and are highly efficient. In contrast, hydraulic machines continuously consume energy to maintain hydraulic pressure, resulting in higher energy consumption.

RELATED VIDEO

MORE INTRODUCTION

- All Electric Vertical Injection Molding Machine, Fits Topics of K 2022

- All Electric Vertical Injection Molding Machine for a More Eco-friendly Future

- Automotive Injection Molding Machine Selection Guide

| Machine Type | Unit | KR-85-D(R) | KR-110-D(R) | KR-150-D(R) | |||

| Screw Diameter | mm | 20 | 25 | 25 | 30 | 30 | 35 |

| Injection Pressure | kg/cm2 | 2500 | 1836 | 2500 | 1736 | 2500 | 1600 |

| Theoretical Shot Volume | cm3 | 31 | 49 | 59 | 85 | 99 | 135 |

| Max. Shot Weight(PS) | g | 29 | 45 | 54 | 77 | 90 | 123 |

| Injection Speed(High Loading Capacity) | mm/sec | 200 | 200 | 200 | |||

| Injection Speed(High Velocity) | mm/sec | 270 | 270 | 270 | |||

| Screw Stroke | mm | 100 | 120 | 140 | |||

| Screw Speed Max. | rpm | 350 | 350 | 350 | |||

| Nozzle Contact Force | tons | 2 | 2.4 | 2.6 | |||

| Nozzle Retraction Stroke | mm | 200 | 250 | 280 | |||

| Number of Temperature Control | - | 3 | 3 | 4 | |||

| Material Hopper Capacity | | | 20 | 20 | 30 | |||

| Machine Type | Unit | KET-40R | KET-70R | KET-100R |

| Clamping Force | tons | 40 | 70 | 100 |

| Dimensions of Rotary Table | mm | 1000 | 1200 | 1400 |

| Mold Thickness | mm | 170~270 | 230~350 | 250~400 |

| Opening Stroke | mm | 210 | 250 | 270 |

| Ejector Force | tons | 1.3 | 2.1 | 2.6 |

| Ejector Stroke | mm | 60 | 60 | 60 |

| Machine Type | Unit | KET-40R | KET-70R | KET-100R |

| Heater Capacity | kw | 2.7 | 3.5 | 4.5 |

| Consumption | kw | 14.6(30Ax380V) | 18(50Ax380V) | 20(75Ax380V) |

| Machine Weight | tons | 3 | 4 | 7.5 |

| Machine Dimensions(L x W x H) | m | - | - | - |