● & NBSP;Идеально подходит для рафийских и пленочных отходов

● & NBSP;Подходит для утилизации твердых отходов

● & NBSP;Shredder интегрировал твердое предварительно измельченное решение для переработки

● & NBSP;Высокоэффективная дегазация, связанная с вакуумным насосом для защиты окружающей среды

● & NBSP;Non-Stop двухканальная поршневая фильтрационная система

● & NBSP;Автоматизация Технология гранулирования методом гранулирования для получения однородных гранул

● & NBSP;система контроля давления и сигнализации

1. Feeding System

Feeding of scraps (raffia, film, lumps) is simple by a conveyor.

2. Shredding

Shredder integrated & Direct feeding to extruder: Powerful yet gentle shredder, efficient size reduction with minimal material degradation. Fast and stable feeding from the shredder into the extruder.

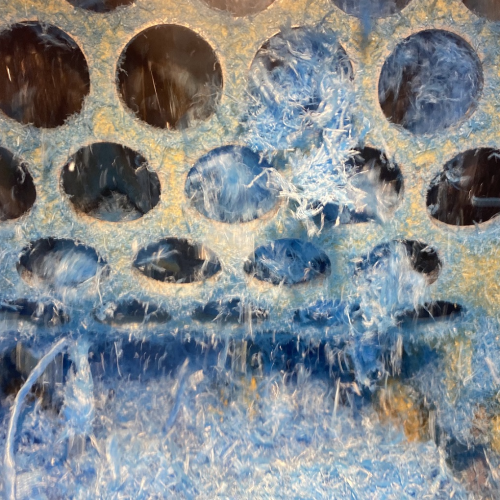

3. Filtration

Screen change with dual channel system: For non-stop operation and prevents material from leaking.

4. Degassing

Two-zone degassing (double-vented degasification): Able to process films with larger printed area and some water content.

5. Pelletization

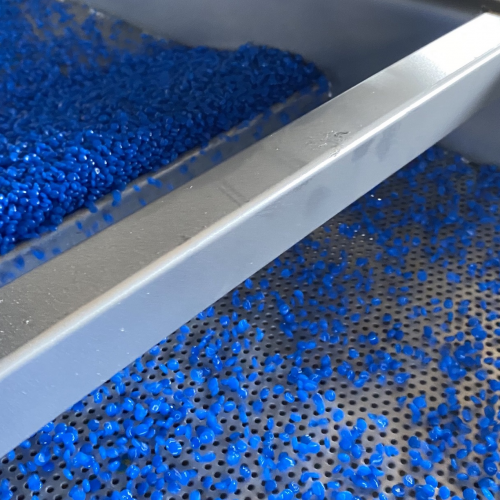

Hot die face pelletizer: Produces high-quality plastic pellets for reprocessing.

6. Recycled Pellets

The plastic pellets can be put directly back into the production line such as blown film extrusion and pipe extrusion.

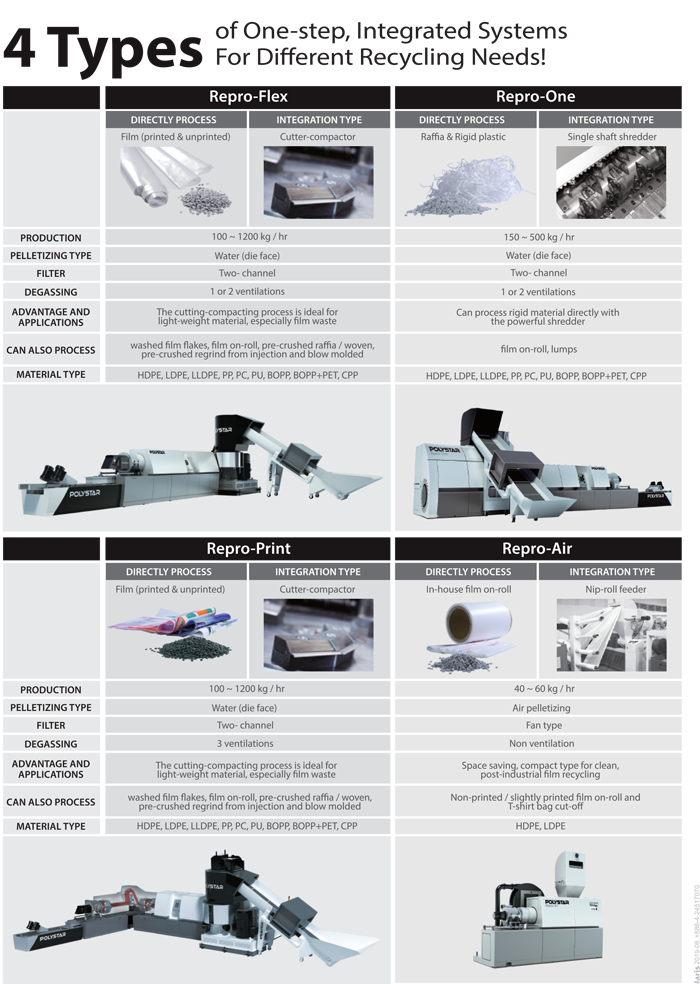

| Название модели | Репро-One |

| Конечный продукт | Пластиковые гранулы / гранулы |

| Компоненты машины | Конвейерная лента, одношнековый измельчитель, экструдер, гранулятор, водяной охладитель, сушильная установка, бункер |

| Перерабатывающий материал | HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, ПК, PS, PU, EPS |

| Выходной диапазон | 150 ~ 500 кг / ч |

| питающий | Конвейерная лента |

| Диаметр шнека | 85 ~ 120 мм (индивидуально) |

| Винт L / D | 30 / 1,32 / 1,34 / 1,36 / 1 (индивидуально) |

| Материал винта | SACM-465 или биметаллический |

| дегазация | Одиночная или двойная вентилируемая дегазация, Не предназначен для непечатаемой пленки (под заказ) |

| Тип резки | Гранулирование гранулированной гранулы (гранулятор для водного кольца) |

| охлаждение | С водяным охлаждением |

| напряжение | Настраивается по запросу (например: США 480 В 60 Гц, Мексика 440 В / 220 В 60 Гц, Саудовская Аравия 380 В 60 Гц, Нигерия 415 В 50 Гц ...) |

| Дополнительные устройства | Металлический детектор (S + S), Присадочный питатель для маточной смеси, Центрифужная сушилка для сушки |

| Срок поставки | 90 ~ 150 дней для индивидуальной машины. В наличии имеющиеся машины |

| Гарантия | 1 год |

| Техническая поддержка | Инженеры, доступные для обслуживания оборудования за рубежом |

| Модель | Репро-One85 | Репро-One100 | Репро-One120 |

| Вывод | 150-250 кг / час; | 300-400 кг / ч & nbsp; | 400-500 кг / ч & nbsp; |

| 6 тонн / день | 9,6 тонн / день | 12 тонн / день | |

| 180 т / месяц & nbsp; | 288 тонн / месяц & nbsp; | 360 тонн / месяц & nbsp; | |

| Диаметр винта | & NBSP; 85мм | 100мм | 120мм |

Plast India an unprecedented Success

The heavy duty single shaft shredder integrated machine generated great interest among visitors from India and other parts of the world at the fair. From day to the last day of the exhibition, Polystar carried our live demonstration of the machine processing different types of material, including PP raffia scrap, purging (lumps), PP FIBC process scrap – bags, webbing, fabric, HDPE, LLDPE film scrap, both printed and unprinted. Visiting customers were able to take a much closer look at the machine performance and the quality of the pellets produced.

The Repro One machine was sold to a PP raffia/PP non-woven manufacturer who will process their in-house process waste and reuse the high quality pellets again in their production process. This manufacturer is one of the recognized producers of PP woven and non-woven fabric and bags in India.

7 sets of Polystar’s recycling machines have been sold at the exhibition along with many more pending projects which are likely to be finalized by mid 2015. Thousands of interested visitors in India registered themselves in Polystar’s stand in 6 days.

The one step recycling machine Repro One has an integration of a heavy duty shredder which eliminates the need of pre-cutting/pre-shredding even hard plastic waste, feeding the waste directly from the shredder into the extruder at a very fast and constant rate without over heating the material. Equipped with double degassing and die face pelletizing, the line is the ideal equipment for processing all types of plastic scrap including PP raffia and woven waste, film scrap, purging, etc.

Apart from Indian clients, the machine also drew great attention from visitors from Middle East and Africa. Some new projects were finalized during the fair for various countries in Africa including Nigeria, Kenya, Morocco, Ethiopia and Tanzania.

With a remarkable success in Plast India, Polystar will again be showing its recycling machines in multiple exhibitions including NPE (Orlando) in March 2015 and K show in 2016 among other prominent exhibitions around the world.

Work with POLYSTAR

An experienced market leader in the recycling field, especially for the recycling of packaging film

More than 1,700 Polystar plastic recycling machines have been installed worldwide since 1988

Proven success and positive feedback from satisfied customers in 105 countries

Flexible, personalized machine design to meet your specific requirement and factory layout

Top quality components used for the machines: Energy saving and high performance motors

Cost-effective machine: Lower investment cost for a high quality and durable machine

Service and Communication

Fast online trouble shooting