LATEST UPDATE Подписывайся

5 Tips to Increase Efficiency in Plastic Recycling Process

In parallel with the increase in the consumption of plastics, driven by economic development and population growth, global plastic waste is projected to triple by 2060 based on OECD reports. Increasing plastic recycling efficiency is one of the major keys to returning more plastic waste to production lines as a valuable recycled polymer. Here we have listed 5 tips to increase efficiency in the plastic recycling process.

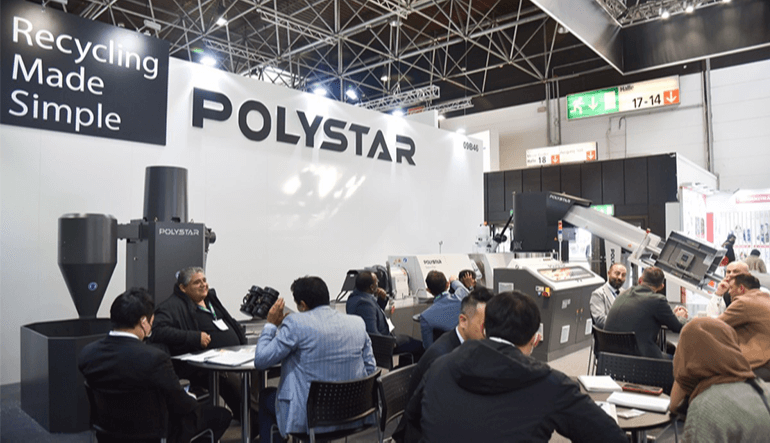

K Show 2022 -Recycling for Post-consumer and Post-industrial Plastics on the Rise

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste.

Recycling for Post-consumer and Post-industrial Plastics on the Rise

It may be good for everyone to be in the plastic recycling business whether you are a recycler or a producer. New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste. With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding.

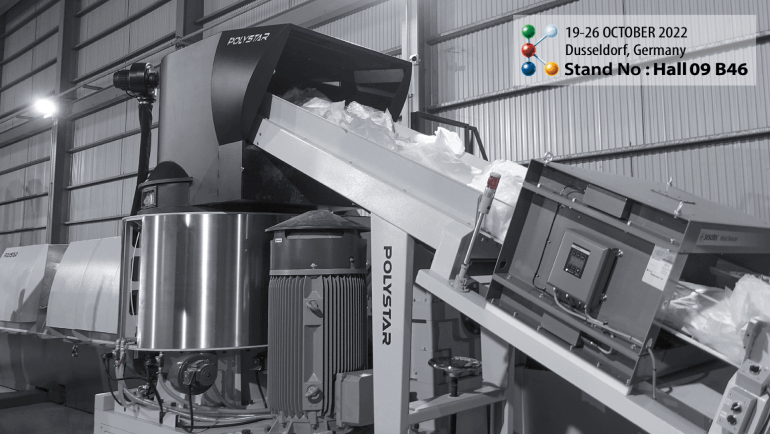

Crucial Factors for a Complete Circular Economy

The production of plastic bags and plastic films around the globe is huge. In recent years, producers have implemented new technologies to complete a circular economy in their factories. To make this possible, producers need a plastic recycling system that produces good quality pellets and a blown film machine that can process up to 100% recycled plastic pellets.

Start Your CPP Film Recycling Right Away with POLYSTAR

Cast polypropylene, also known as CPP, is well known for its versatility. CPP is gaining popularity as a more appealing packaging material than polyethylene in many areas because it has higher clarity and better heat resistance. The qualities of the CPP film can be customized to fit specific packaging, performance, and processing needs...