LATEST UPDATE Подписывайся

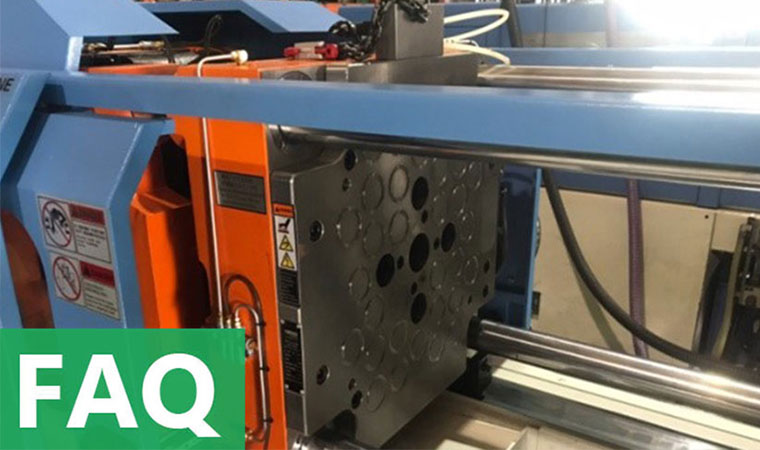

Magnetic Clamping System FQA

In the current environment, it is a good time to introduce magnetic clamping system, only need one operator. This reduces labor costs and labor consumption, and the mold change speed is faster than hydraulic clamping. The latest magnetic structure and outstanding design of magnetic circuit achieves a 20% and more of the magnetic force than traditional magnetic plate design. And SANDSUN magnetic clamping have 8 special safety function designs.

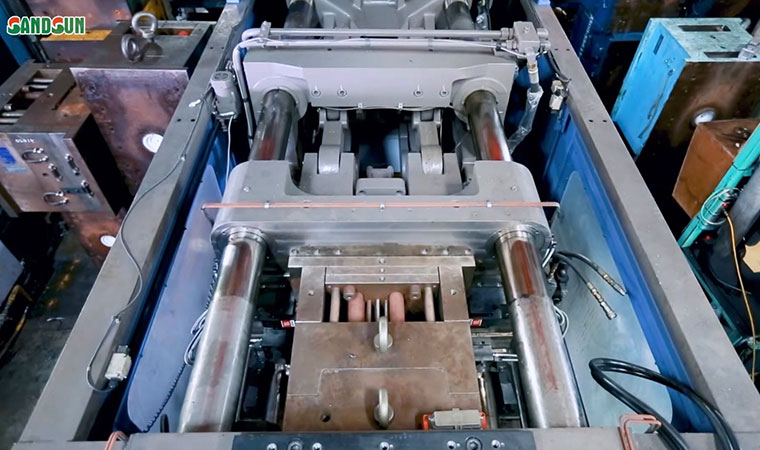

5 Tips for Efficient Injection Molding Mold Change Procedure

Regardless of the metal stamping production line or the injection molding production line, mold changing s often one of the most time-consuming procedure, and a lot of intangible waste is also generated during mold changing. In addition, in traditional mold changing process, which must rely on the master’s experience to set molds and adjust molds. However, this technical work has been gradually lost. The younger generation of employees are less willing to engage in mold changing work because this job is relatively dangerous and tired.