LATEST UPDATE Подписывайся

Eterlong in PLAST EURASIA ISTANBUL 2023 and Plastivision India 2023

Eterlong Co., Ltd. is pleased to participate in the annual events PLAST EURASIA ISTANBUL 2023 and Plastivision India 2023 with great enthusiasm. As our growing audience discovers the potential of impressive products demonstrations, fruitful buyer-seller meetings, and engaging discussions with industry professionals, People's expectations for the products and services Eterlong can offer are higher than ever.

The Largest Fair in the European Region Makes a Name for Itself

Plast Eurasia Istanbul 2023, the 32nd International Istanbul Plastics Industry Fair, was held at Tüyap Fair and Congress Center in Istanbul, on November 22-25, 2023. The largest technology, innovation and information sharing, and also a giant trade platform for the plastics industry, the Plast Eurasia Fair once again maintained its position in the industry.

Friendship and Excellence: Chi Chang's Formula for Global Extrusion Success

Taiwan, a small island located in East Asia, manufactures a diverse range of machinery, and also includes consumer products used in our daily life, may come from a prominent player from Taiwan. There's a leading company which specializes in producing extrusion equipment in Taiwan — Chi Chang Machinery, known for its high-quality machines and being the first Taiwanese extrusion equipment manufacturer to export to high-end markets.

TOP 6 BLOW MOLDING EXAMPLES BY EXTRUSION BLOW MOLDING MACHINES

There are lots of Extrusion Blow Molding(Moulding) Products in our daily life. Blow molding is a manufacturing process for forming and joining together hollow plastic parts. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding (one stage), and injection stretch blow molding (two stages). In the extrusion blow molding process (EBM), plastic is melted and extruded into a hollow tube (a plastic parison). This plastic parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected. It is designed to manufacture high volume hollow plastic products.

TungYu's Pathway To Net-Zero Emissions In 2050

TungYu is actively undertaking a comprehensive carbon footprint reduction plan to meet the challenges of achieving net-zero emissions by 2050. The initiative targets greenhouse gas inventory, product carbon footprint, and low-carbon and energy-efficient design throughout the product lifecycle, implementing a range of specific measures to achieve sustainable development goals.

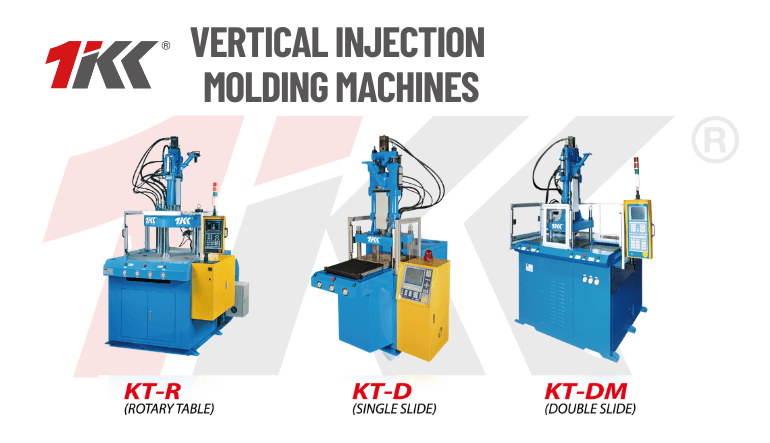

TAIWAN KINKI's Key Role in Elevating Manufacturing in the Global

Taiwan Kinki Machinery (TKC) is a professional and experienced Taiwanese manufacturer dedicated to all kinds of vertical injection moulding machines, that service thousands of factories and enterprises across the globe, producing various equipment and consumer goods. TKC’s machines are well-known for their precision and efficiency, and several international manufacturers pursuing best-quality products have chosen and purchased TKC’s machines in the past decades.

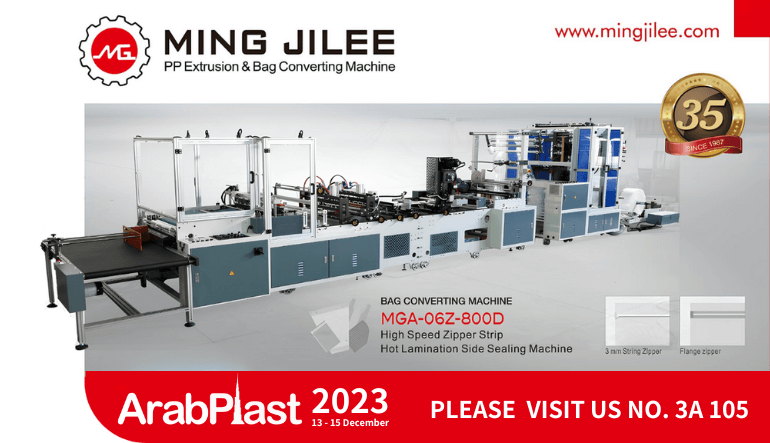

MING JILEE: Bag Converting Machine Experts since 1987

HighSpeed Zipper Strip Hot Lamination Side Sealing Machine, MGA-06Z-800D. Zipper bag side sealing machine is the latest design to produce zipper bag / Ziploc bag / IKEA zipper bag/ grape bag/ slider zipper bag. The zipper bag side sealing machine is equipped 3 sets of servo motors to control the best tension and high speed production. The zipper bag side sealing machine is equipped in-line zipper strip sealing station.

PLASTICS & RUBBER INDONESIA 2023: Support Industry Participants in their Endeavours to Innovate and Realize the Green Industry

Jakarta - November 15th, 2023 - Plastics & Rubber Indonesia 2023, the 34th edition of international plastics and rubber machinery, processing and materials exhibition is taking place at the Jakarta International Expo(JIExpo) Kemayoran until November 18th, 2023. Themed The Future of Plastics, the exhibition is committed to drive the adoption of green industrial practices to further boost domestic industry growth.

POLYSTAR's Exponential Growth in Türkiye Fueled by Delighted Customers!

Post-industrial and post-consumer plastic recycling activities are rapidly growing in Türkiye and contribute to environmental as well as economic sustainability. POLYSTAR is proud of standing with Turkish plastic recyclers and manufacturers by providing simple-to-use yet efficient plastic recycling machines. Today, over 45 POLYSTAR machines operate in Türkiye.

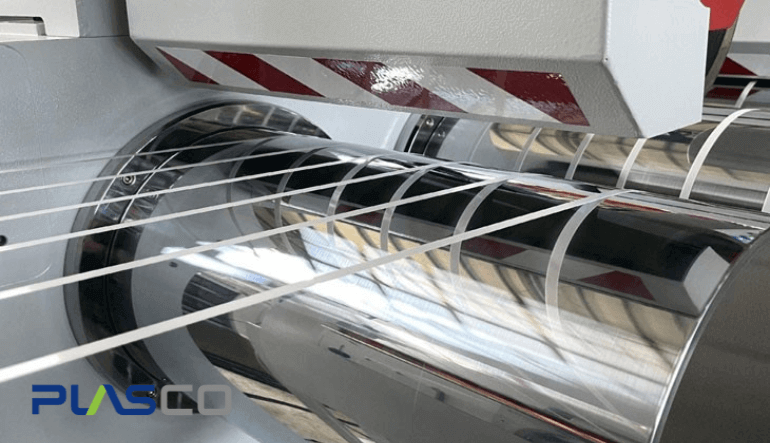

PLASCO: The Essential Reference of Strapping Band Extrusion Machines

Within the packaging industry, PP/PET strapping band making machines stand as vital equipment. These machines are employed in the production of strapping bands, which serve to secure a diverse range of goods, such as boxes, pallets, and drums. The utilization of PP/PET strapping band extrusion machines yields enhancements in packaging efficiency, cost reduction, and safety improvements. Our discussion will encompass the components, varied strapping band grades, their applications, as well as a comprehensive buying guide for PP/PET strapping band extrusion lines.

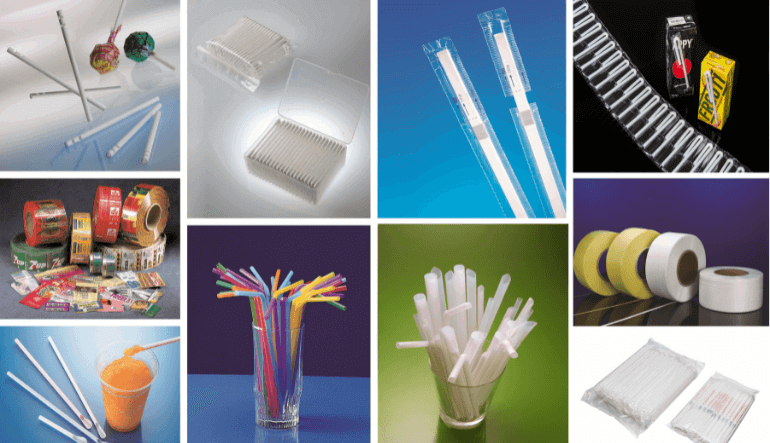

Jumbo Steel: Pioneering a New Era in Straw Manufacturing

With customers spanning over 120 countries and a primary focus on the US market, Jumbo Steel Machinery Co., Ltd. has been a leading manufacturer of biodegradable/PP straw-making machines and turnkey equipment since its establishment in 1986. Their flagship products encompass a range of machinery related to straw production, from straw bending and spoon straw-making machines to straw packaging and automatic bagging equipment, showcasing the company's expertise in automated production.

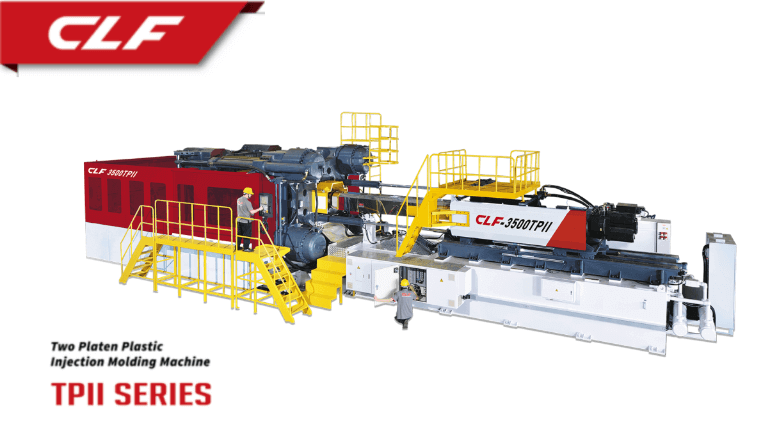

CLF Advanced Production Efficiency: Cycle Time Reduction in Two Platen Injection Molding Machine

Chuan Lih Fa (CLF) Machinery Works Co. Ltd, a decades-old global manufacturer of diverse plastic injection molding machines, has lately made a breakthrough with their Two Platen Injection Molding Machine. CLF’s R&D team has successfully improved the cooling system and developed a multi-circular system, which resulted in an exceptionally high-speed cycle time.