Recycling Materials with POLYSTAR for New End Product Possibilities

With consumers increasingly pushing for less raw material usage, the last few years have exhibited an increase in recycled plastics as basic materials for production, helping repurpose products that otherwise would be considered waste. But what type of plastic materials can be recycled? How can plastics be recycled? And what end products can be made using recycled materials?

Which plastic materials can be recycled?

Ideally, all plastic types can be recycled, but the most common recyclable plastic materials are LDPE/ LLDPE, HDPE, PP, BOPP, CPP, ABS, PS, EPS, and others. Producers can begin by recycling plastic types with similar properties such as the ones mentioned above as they can be recycled in the same type of machines with similar processes.

How can plastics be recycled?

Plastic materials can be recycled by using“pelletizers”or recycling machines. These machines take plastic waste to melt it, remove gases, filter it, and cut it into small-sized particles called“pellets,”which can be used to produce virtually any plastic product.

Materials can be recycled using an innovative, yet simple pelletizing system called die face or water ring pelletizing, this technology renders a highly efficient and automatic process, producing round-shaped pellets of uniform size.

What end products can be made using recycled plastics?

Recycled plastics in pellet form can be used for producing almost the same type of products as raw materials (except for products that need to be in direct contact with food). Some examples of the most common products made from recycled materials include trash bags, injection molding or blow molding, plastic bottles for products such as detergent or shampoo, plastic lumber, buckets, containers, kid play sets, carpeting, etc.

Lately, these recycled materials have been used for many other different innovative applications such as shoe soles, laces and foam components, stadium seats, clothes, sweaters, jackets, sportswear, countertops, bed sheet comforter stuffing, purses, eyewear frames, and many more.

POLYSTAR recycling machines for simple and efficient production

|

|

|

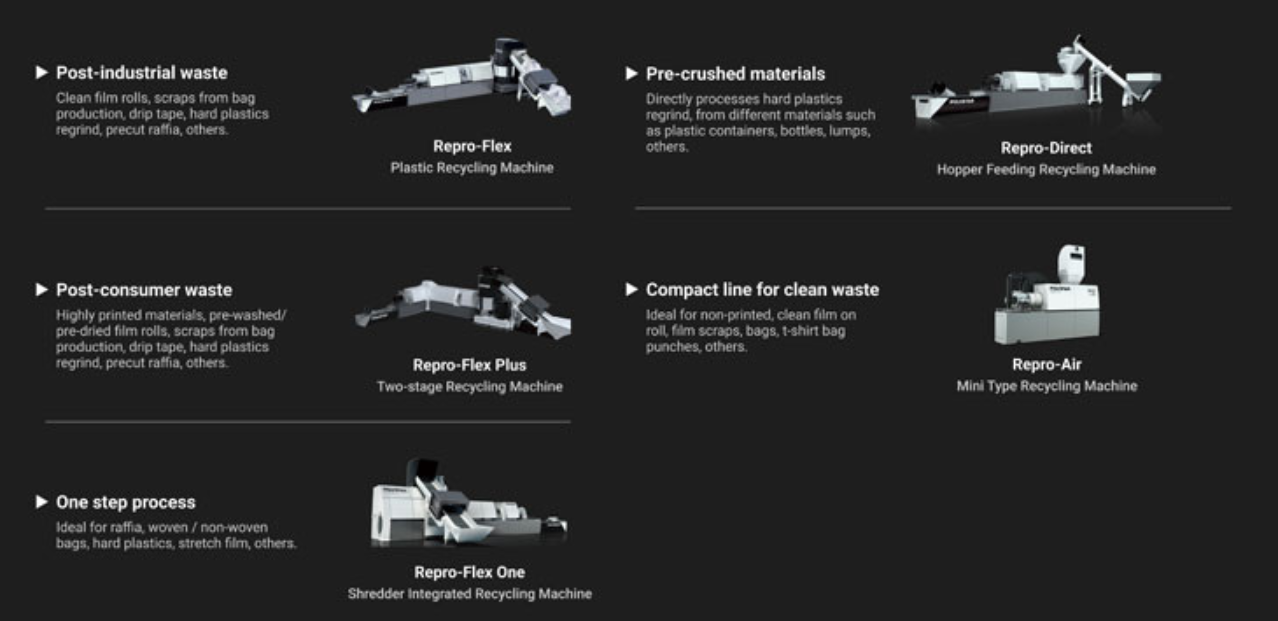

The machine needed for processing each material will depend on the shape and condition of the plastic residues to be recycled. Materials such as film rolls, scraps from bag production, drip tape, hard plastics regrind, precut raffia, and many other factory wastes can all be recycled using the Repro-Flex Recycling Machine from POLYSTAR. This machine integrates a precutting and preconditioning unit called a Cutter Compactor, which allows the flexibility to process a wide range of materials.

For materials from post-consumer waste, the process is very similar. The main difference when processing these materials is that they need to be washed and dried before being fed into the recycling machine. The machine needed to process this type of waste is called Repro-Flex Plus, which integrates an additional station for further ink, humidity, and impurity removal.

For “clean waste” or post-industrial waste such as factory scraps, startup waste, defective products, lumps, and many more. There are other machine options such as the Shredder Integrated Recycling Machine, Repro-One, which allows direct feeding of hard materials such as plastic lumps or containers without the need to pre crush; or the Hopper Feeding Recycling Machine, Repro-Direct, which is specially designed to process hard plastics regrind.

For producers who need to process small amounts of film waste, there is also a Mini Type Recycling Machine called Repro-Air, which offers an affordable and compact way to recycle clean waste in film form.

Successful producers using recycled plastics back in production

The use of recycled materials back in production has already been adopted by many plastic producers, with some recycling their factory waste and other clean waste from other producers like Sürmeli Plastik in Turkey to even collecting waste from outside sources to reduce the environmental impact of the products like Plasticonsumo in Ecuador.

With regulations in many countries already requiring the use of recycled materials in production, we strongly encourage producers who aren’t recycling their waste to begin as soon as possible, as this can help move the industry toward the circular economy goal as well as incentivize consumption of your product.

Learn more:

POLYSTAR linkedin: https://www.linkedin.com/company/76949389/admin/