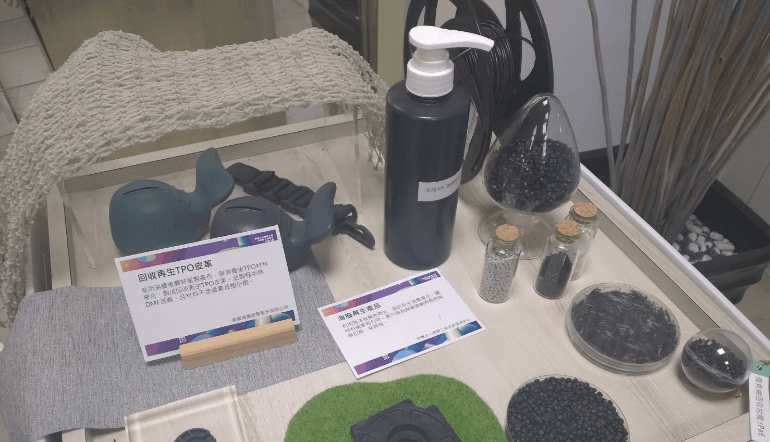

GRECO's Eco Sustainable Material Series Unveiled at 2024 TaipeiPlas Exhibition

At the upcoming 2024 TaipeiPlas Exhibition, GRECO will proudly introduce our latest Eco Sustainable Material Series, designed to meet the high demands for environmental responsibility, recyclability, and quality across various industries. This new series is tailored for the footwear, sports equipment, electronics, textile, and plastic products sectors, perfectly blending environmental principles with exceptional performance.

FORMAX: Precise Measurement is Key to Success

Precise measurement is the key to success Formax: “Attention to detail is what maximizes value.” Founded in 1992, Formax is committed to becoming a leader in the global plastics processing industry. Equipped with strong R&D capabilities, we provide professional, high-quality, high-performance plastics auxiliary equipment and automation systems to create the utmost value for our clients. As an expert in production systems, FORMAX believes its expertise can help clients enhance efficiency and solve quality issues in production. FORMAX embraces "Precision, Aesthetics, Operation Convenience" in reestablishing the focus of its R&D and undergoes comprehensive enhancement for its central conveying systems, dosing and mixing equipment, feeding and conveying equipment, drying and dehumidifying equipment, heating and cooling equipment, as well as its granulator and recycling equipment; ensuring that FORMAX product series continue to add value to the global plastics industry.

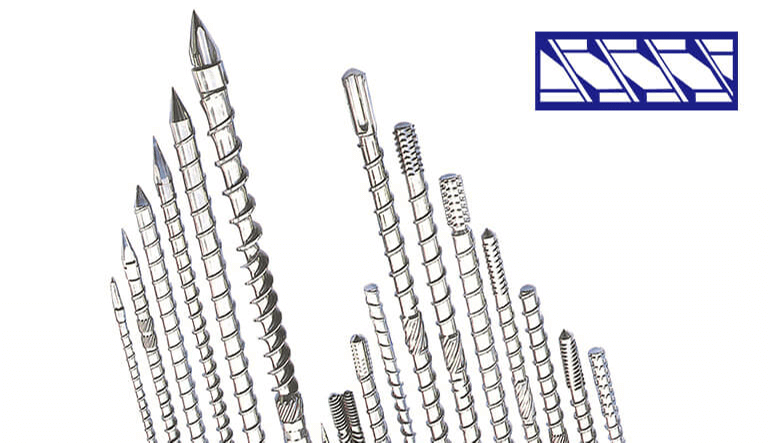

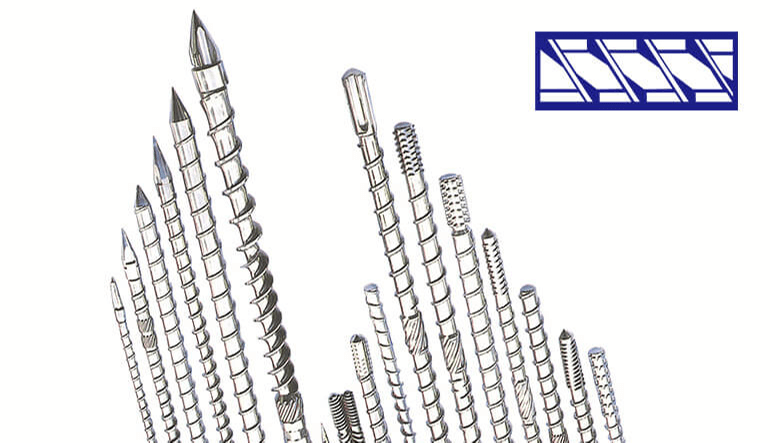

Customized Perfection: How LUNG CHANG Meets Clients’ Needs with Precision Screws and Barrels

During the pandemic, one of the biggest challenges for the plastic machinery industry is the travel and logistics limitations. No matter after sales services of the manufacturers are good, once it comes to the maintenance and parts requirements, current transportation and logistics obstacles might cause the manufacturers delay in their business. Therefore, many plastic machine manufacturers prefer to use the parts, such as screws and barrels, that are high quality and meet customers' requirements precisely in their machines. In this case LUNG CHANG is one step ahead in the industry with its reliable extruder screws and barrels as well as injection molding machine screws and barrels.

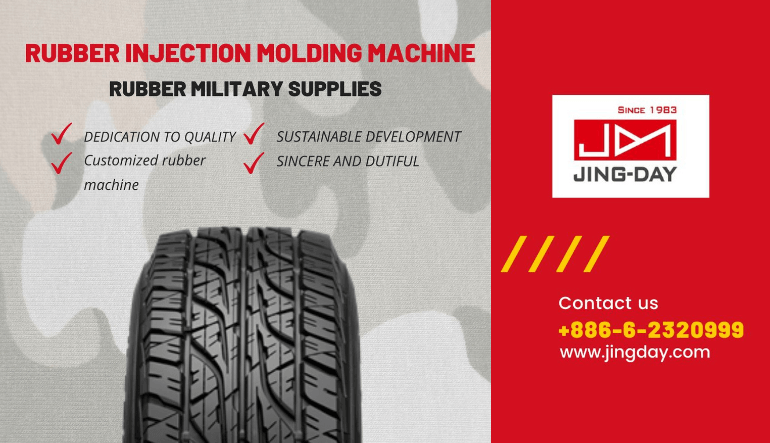

JingDay: A Pioneer in Rubber and Silicone Molding Technology, Forty Years of Expertise Yielding Diverse Applications

Rubber and silicone are no longer unfamiliar materials to most people. With their excellent elasticity, insulation, heat resistance, cold resistance, and outstanding electrical properties, it's easy to spot applications of silicone rubber in daily life. Since its establishment in 1983, JingDay Machinery, with its 40 years of knowledge and technology in rubber and silicone molding, has not only developed various specialized machinery for customers but also covered application fields such as automotive, motorcycles, 3C products, medical, sports products, and golf products.

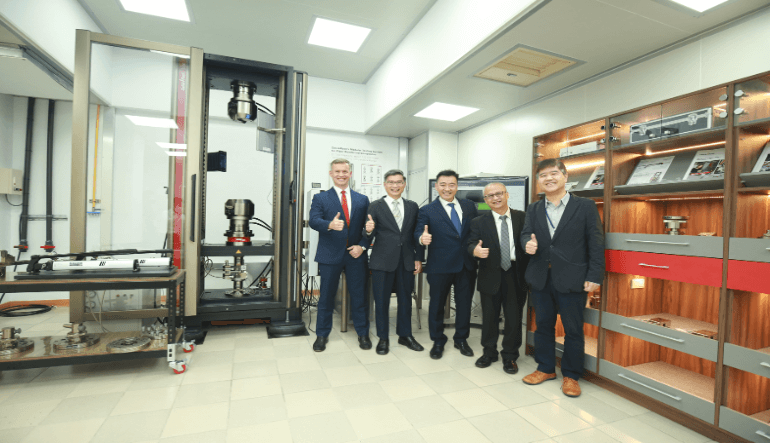

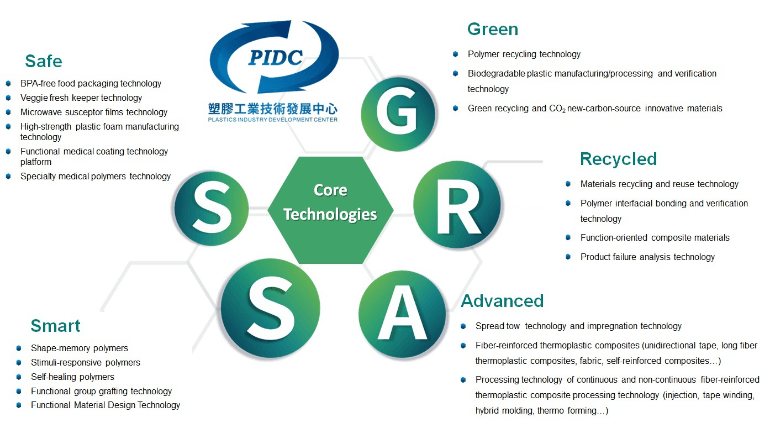

台德合作!塑膠中心促亞太區複材實驗室成立

【新唐人亞太台 2022 年 11 月 24 日訊】 第3屆塑膠產業創新論壇週三(23日)登場,今年以塑膠產業永續發展為題,推出2場論壇及技術研討會系列活動,展出超過100項的焦點技術,吸引塑化業者超過300位出席。 由塑膠中心邱政文副總經理於擔任座談交流會主持人,分享複材產品研發國內已具備技術實力,有賴各界合作,共朝創新高值產品如航太、國防等高階領域開創。天力技術處長王柏棋、塑膠中心博士張修誠,以及虎科大飛機工程系助理教授王正賢,也分享產業技術發展和關鍵人才養成。

Introduction to ETERPLAST™

ETERNAL ETERPLAST™ thermoplastic composite materials have the characteristics of high strength, high impact resistance, low moisture absorption, high dimensional stability, and repeatable molding. Different temperature-resistant materials can also be provided according to customer needs.

JING DAY: The Strategic Role of Rubber Military Supplies in Modern Warfare

Rubber has long been a crucial material in various industries, and its significance extends to the military domain. From tires to protective gear, rubber plays a pivotal role in enhancing the effectiveness and survivability of armed forces around the world. In this article, we will explore the diverse applications of rubber military supplies and their strategic importance in modern warfare.

JING-DAY: Customized Rubber Injection Machines for Highly Specialized Applications

Research, mold making, and production can be considered as critical processes in rubber molding technology. Jing-Day Machinery, originating from Taiwan, has accumulated over 40 years of knowledge and expertise in rubber and silicone molding since its establishment in 1983. This expertise allows them to excel in crucial technologies, enabling them to develop various specialized machinery and equipment for clients across a wide spectrum of industries.

落實永續循環:塑膠中心打造低碳新包材

在氣候變遷、地球暖化的壓力下,低碳淨零永續已是全球共識與重要積極作為,歐盟與美國等先進國家先後發佈一次性塑膠製品限用、回收政策與淨零碳排之相關規範,如歐盟與美國直接要求2025年底前,所有包裝材料必須含有25%的回收料。此外,塑橡膠廠商亦不斷探尋具高值潛力的低碳永續材料,以及回收塑料再生的開發,打造完整上中下游的綠色經濟產業鏈。

Aluminum Idler Rollers – Perfect for installation on web presses and converting machinery | TOP ROLLER

For more than 30 years of producing high quality Idler Rollers, Top Roller has been the premier supplier for the Printing Machinery Industry, Plastic Extrusion Machinery Industry, and Paper Industry worldwide.

Customized with High Performance. Your best partner for Bio TPU , ETPU , LFRT and ABS | GRECO

ISOTHANE TPU resins are high quality environmental friendly materials and available in a wide range of hardness in polyester and polyether-based formulations. ISOTHANE exhibit the valuable characteristics of flexible rubber and rigid plastics and their wide spectrum of mechanical properties can meet customers’ demands in extensive applications. ISOTHANE TPU portfolio includes non-plasticizer soft grades, high transparency grades, hot melt grades, breathable film grades, medical/biocompatible grades, engineering grade, low compression grades, bio-renewable grades (Between 25~60% Bio-based), flame retardant grades, calendaring grade and TPU adhesion grades and special compounds like TPU with 40%, 50%, 60% Long Fiber Reinforced Compounding Materials (TPU LFRTs).

Plastics Innovation Towards ESG Sustainability

In response to the global trend of sustainable development and net-zero emissions, the innovation in the plastics industry is closely tied to the three dimensions of ESG (Environmental, Social, and Governance) sustainability. This has become a focal point of global industry innovation opportunities, and companies that can balance ESG sustainability while pursuing economic growth are now crucial.

JING DAY: The Best Customized Rubber Injection Machines for Automotive Parts and Components

According to rubber industry studies, it is expected that the rubber injection machine market will have a moderate growth during the present time to 2027. This is due to the changes occurring in the market, such as: fast production of rubber products, minimum wastage of material, low labor cost, and flexibility in material, color, and design.

HUARONG Launches Optimized Two-Platen Injection Molding Machine and Composited Injection Blow Molding Machine

Huarong is a Taiwanese manufacturer of injection molding machines for more than 40 years. "Industrial alliances create value for customers " as the core spirit for Huarong, being a worthy injection molding partner for customers is what Huarong insists on.

JING DAY: Automation of Rubber Injection Moulding Machines

While crowds cheer and television audiences tune in to watch professional athletes test their skills against one another, few will give any immediate thought to something as seemingly banal as rubber — but rubbers play a significant role.

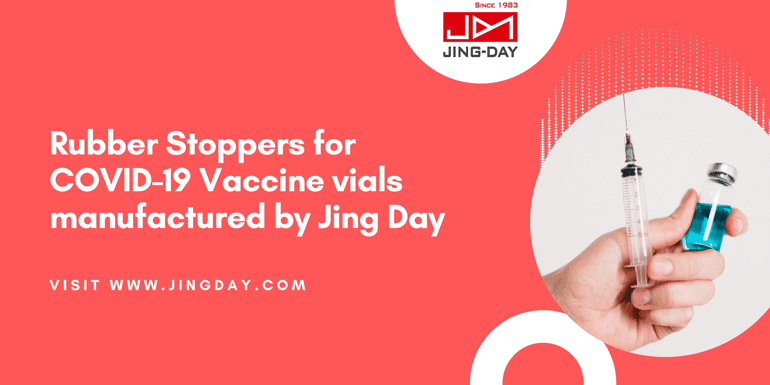

Rubber Stoppers for Vaccine Vials Manufactured by Jing-Day

There is no COVID-19 vaccination without those sterile rubber stoppers which seal each high-purity vaccine vial. These stoppers are being manufactured on special presses designed by Jing-Day Hydraulic Presses. In this year, suppliers of the international pharmaceutical industry awarded Jing-Day with a lot of order of these stopper presses.

LUNG CHANG Cultivates the Trust of Manufacturers through Customized Screws and Barrels

During pandemic COVID-19 one of the biggest challenges for the plastic machinery industry is the travel and logistics limitations. No matter after sales services of the manufacturers are good, once it comes to the maintenance and part requirements, current transportation and logistics obstacles might cause the manufacturers delay in their business. Therefore, many plastic machine manufacturers prefer to use the parts, such as screws and barrels, that are high quality and meet customers' requirements precisely in their machines. In this case LUNG CHANG is one step ahead in the industry with its reliable extruder screws and barrels as well as injection molding machine screws and barrels.

JING DAY: Pioneer Silicone and Rubber Injection Molding Machines for Electric Vehicle Market

The sales of electric vehicles (EV) are increasing day by day in the world. Due to aiming to reduce greenhouse gas emissions for less polluted air, using electric vehicles is encouraged by governments worldwide through different types of financial measures, including tax and purchase incentives. This positively affects the global silicone and rubber market. The market size was valued at USD 971.8 million in 2017 and expected to observe an annual growth rate of 8.1% from 2018 to 2025 according to the report of Grand View Research.

JING DAY: Expert of Medical Silicone Rubber Injection Molding Machines

Recently, there is huge demand emerging for rubber and silicone molded products for medical device components due to the epidemic COVID-19, as well as the requirement in several industries

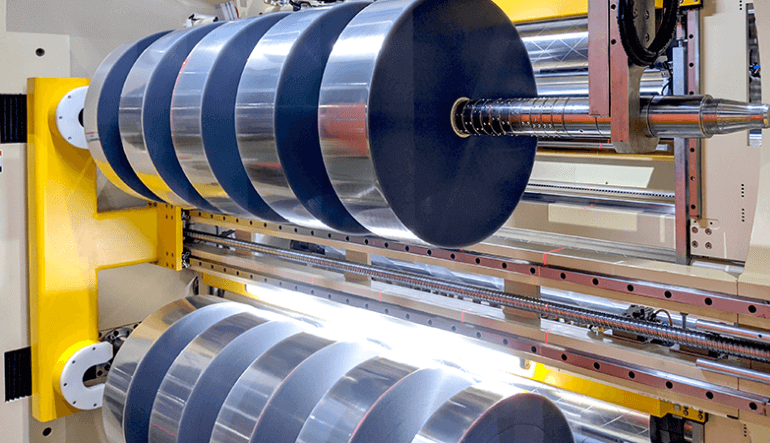

Flexible Packaging Film Slitting : Understanding Process and Select the Right Slitter

Flexible packaging is fundamental in providing protection and enhancing the visual appeal of consumer products. Central to the operations of this industry is the slitting process for flexible plastic films—which is a mechanism that significantly influences the efficiency and quality of the output.

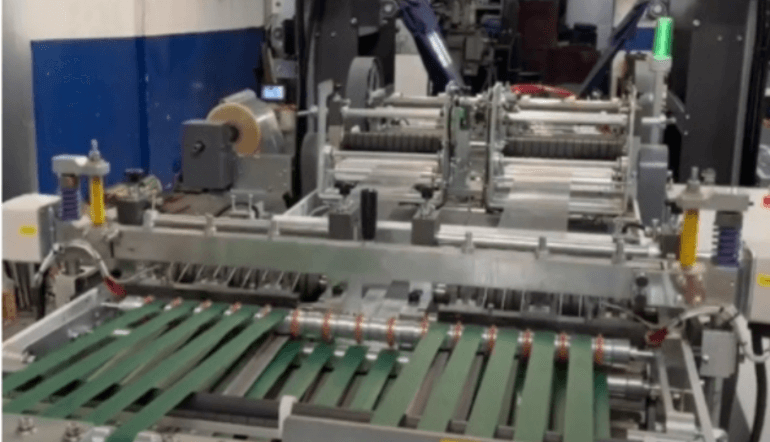

Plastic Bag Folding, Sealing & Cutting Combo Machine : Boost Your Efficiency with This All-in-One Solution

At World Steel Machinery, we understand that innovation drives success in the manufacturing industry. Our Plastic Bag Folding, Sealing & Cutting Combo Machine is an automated bag-making solution designed to streamline production by integrating plastic film folding, sealing, and cutting into one efficient system. This multi-functional packaging machine ensures faster, more efficient bag production, helping businesses reduce costs and increase output.

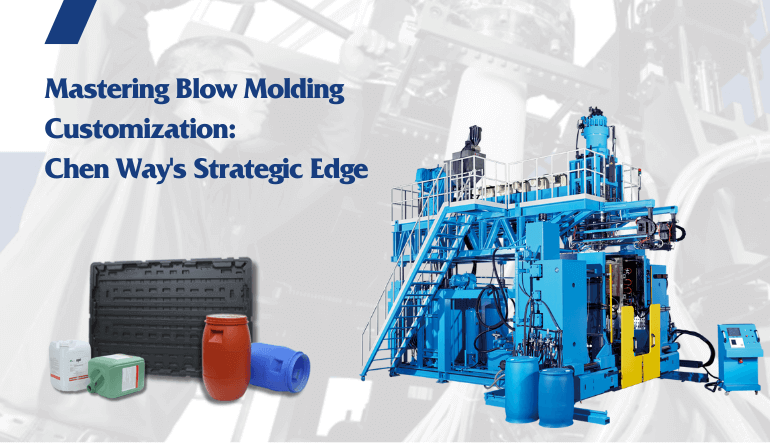

Mastering Blow Molding Customization: Chen Way's Strategic Edge

In the dynamic world of manufacturing, the ability to offer tailored solutions that meet specific client requirements is a significant competitive advantage. Chen Way Machinery (進韋機械), a leading player in the Plastic Blow Molding machinery sector, exemplifies this capability through its extensive range of products and exceptional customization services. This article delves into Chen Way Machinery's offerings, success stories, and the factors that make it a preferred choice for international machinery buyers.

TungYu: Revolutionizing the Industry and Shaping a Greener Future

TungYu, a name synonymous with innovation in the rubber industry, is thrilled to announce our participation in two of the most prestigious industry events: RubberTech 2024 in Shanghai, China, and TaipeiPlas 2024 in Taipei, Taiwan. At TaipeiPlas 2024, TungYu will be focusing on the theme of "Shaping a Greener Future of Sustainable Forming Technologies.

TungYu Servo Press: Revolutionizing Manufacturing with Sustainable Power

Are you looking to enhance your manufacturing processes while minimizing environmental impact? TungYu's advanced all-electric servo press offers a sustainable and efficient solution. By replacing traditional hydraulic systems with high-performance servo motors, our servo press achieves significant energy savings and a reduced carbon footprint.

WORLD STEEL: Build Your Flexible Production Line

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, we have the best engineering crew in the industry to provide total solutions which include design, customization and development. To meet customer needs, we are committed to developing new models and increasing product competitiveness.

Plastic Drums and Plastic Drum Machines: A Quick Guide

Blue HDPE plastic drums are very common containers in warehouses and transport facilities across the world. These sturdy and durable containers are not only cost-effective but also incredibly useful when it comes to the safe and secure storage and transport of many different industrial goods. Given their popularity, plastic drum-making machines are also in constant demand by customers who seek effective solutions for their industrial businesses.

MOLDPOWER is Looking for Hot Runner System Distributors Worldwide

In 1997, Mr. Chen, Chung-Le and Mr. Chen, Ya-Mo co-founded Mold Power Co. Our core-values are honesty, quality, expertise, and a better future together. We are devoted to the design and the manufacturing of hot runner systems and originated the brand “Mold Power”. Because of our superior product performance, our products have been adopted by quite a few domestic mold plants for appliances, food containers, cosmetics, automotive parts, medical supplies, electronic products etc.. We provide customers with complete products and technology sharing.

Full Shine Machinery's Expertise in PC Water Bottles Making Machine

Full Shine Machinery has 30 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.

Discovering Latest TungYu Solutions at 2024 Rubber and Plastics Exhibition

As part of its corporate development strategy, we will participate in the Global Rubber and Plastics Exhibition in 2024. This international exhibition brings together top companies and experts from the global rubber and plastics industries. Participation in this exhibition will provide TungYu with a platform to showcase its latest technology and products, engage in exchanges and collaborations with peers from around the world, and further enhance the company's international influence.

40th Techmation: Digital Low Carbon Dual Wheel Drive, Intelligent Manufacturing in the Future

2024 marks the 40th anniversary of Techmation. Over the past 40 years, Techmation has taken the first Chinese screen injection molding machine controller in Asia as the starting point, vertically breaking through technological barriers, horizontally expanding product applications, and steadily drawing an industrial application map with Techmation control system as the core.

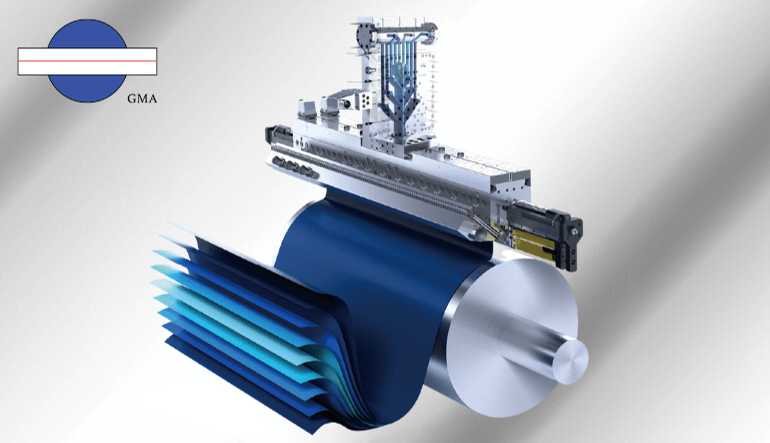

GMA Machinery's Evolution from Extrusion die Craftsmanship to Slot Die and Coating Equipment - A Journey of Unwavering Excellence

For over 30 years, GMA Machinery, with its rich experience in extrusion die design and manufacturing, has caught the attention of global extrusion machine market. What prompted GMA Machinery to smooth transition from specialized extrusion die design and manufacturing to enter the slot die and coating equipment and equipment sector? How did it swiftly emerge as the new choice for slot die and coating equipment in the optoelectronics and precision manufacturing industries?

TOP 6 BLOW MOLDING EXAMPLES BY EXTRUSION BLOW MOLDING MACHINES

There are lots of Extrusion Blow Molding(Moulding) Products in our daily life. Blow molding is a manufacturing process for forming and joining together hollow plastic parts. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding (one stage), and injection stretch blow molding (two stages). In the extrusion blow molding process (EBM), plastic is melted and extruded into a hollow tube (a plastic parison). This plastic parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected. It is designed to manufacture high volume hollow plastic products.

TungYu's Pathway To Net-Zero Emissions In 2050

TungYu is actively undertaking a comprehensive carbon footprint reduction plan to meet the challenges of achieving net-zero emissions by 2050. The initiative targets greenhouse gas inventory, product carbon footprint, and low-carbon and energy-efficient design throughout the product lifecycle, implementing a range of specific measures to achieve sustainable development goals.

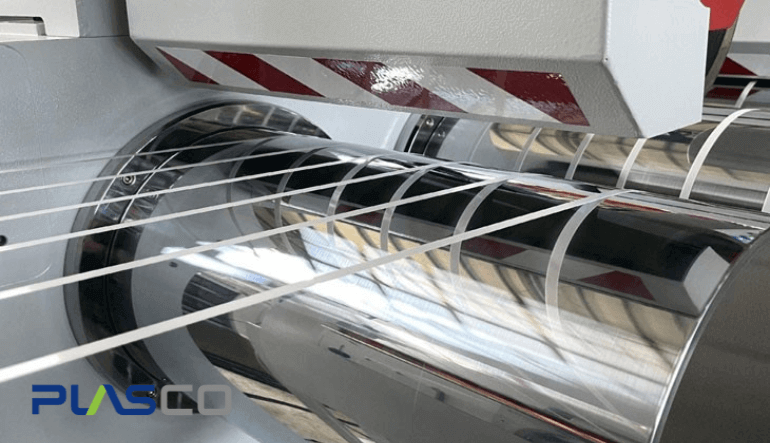

PLASCO: The Essential Reference of Strapping Band Extrusion Machines

Within the packaging industry, PP/PET strapping band making machines stand as vital equipment. These machines are employed in the production of strapping bands, which serve to secure a diverse range of goods, such as boxes, pallets, and drums. The utilization of PP/PET strapping band extrusion machines yields enhancements in packaging efficiency, cost reduction, and safety improvements. Our discussion will encompass the components, varied strapping band grades, their applications, as well as a comprehensive buying guide for PP/PET strapping band extrusion lines.

CHEN WAY : How to Select the Correct Blow Molding Material for Your Products

Extrusion blow molding machines can produce a wide variety of hollow plastic products. It is important to keep in mind that in order to produce exceptional products, besides purchasing high-quality Blow Molding Machines, it is also crucial to choose the correct blow molding material for each project. This ensures that the end products will have the desired properties and will also be able to withstand the environment(s) that they will be exposed to.

Here are 10 key points to understand extrusion dies.

This article explores extrusion dies, a vital component in the plastics industry. It focuses on "flat extrusion dies," which create uniform sheets and films by guiding polymer material through a chamber. The die's structure includes a body, width, and thickness adjustment systems. Extrusion dies find applications in various industries, from stationery boards to automotive films. The manufacturing process involves precise machining and finishing.