Insert Molding vs. Overmolding: Key Differences & Applications

In the field of plastic product manufacturing, Insert Molding and Overmolding Molding are two widely used techniques, each serving different purposes. Understanding their differences is crucial for selecting the right manufacturing process, especially in OEM car parts, consumer electronics, and medical devices.

North America's Economic Reboot: Mexico Joins the Internal Circulation Wave

PLASTIMAGEN 2025 will take place from March 11 to 14, 2025, at Centro Citibanamex in Mexico City, attracting top professionals from the global plastics and rubber industry. As the largest plastics processing exhibition in Latin America, PLASTIMAGEN offers an unparalleled platform for buyers to explore market trends, discover new technologies, and establish valuable business connections. With Mexico’s plastics industry valued at $28.6 billion, this event presents a golden opportunity to expand your presence in one of the fastest-growing manufacturing markets in the world.

Zhenxiu’s Plastic Injection Molding Machines: Precision, Insert Molding & Overmolding Solutions

In today’s competitive manufacturing landscape, precision, efficiency, and cost-effectiveness are crucial for maintaining product quality and profitability. Zhenxiu Plastic Enterprise specializes in plastic injection molding machine solutions that optimize production for industries such as automotive, electronics, and consumer goods. By leveraging advanced injection molding machine technology, Zhenxiu ensures seamless production, whether through insert molding for durable metal-plastic integration or overmolding to enhance aesthetics and functionality.

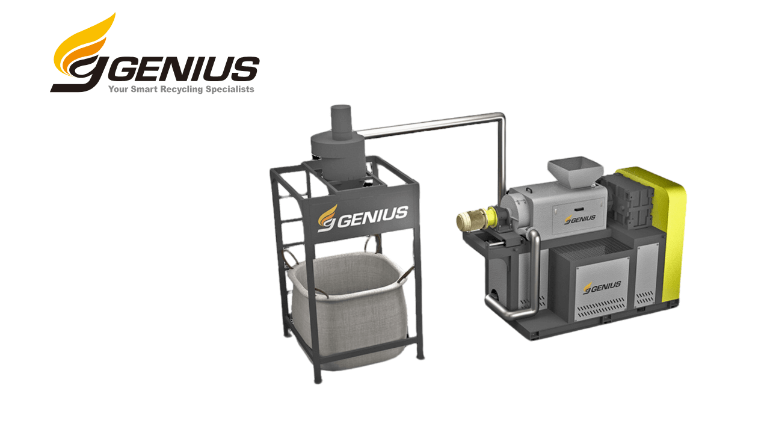

How Screw Press Dewatering Machines Revolutionize Plastic Film Recycling | GENIUS

Plastic waste has become a major environmental challenge, particularly with the growing use of plastic films in agriculture, packaging, and various industries. Recycling plastic films such as agricultural film and stretch film requires efficient dewatering to improve material quality and reduce waste.

Medical Tube Extrusion Line : Key Insights and Case Studies | Twin Screw

In medical manufacturing, precision, efficiency, and reliability are critical to producing life-saving devices. PVC Medical Tube Extrusion Lines play a pivotal role in manufacturing essential products like IV lines, catheters, and respiratory tubes.

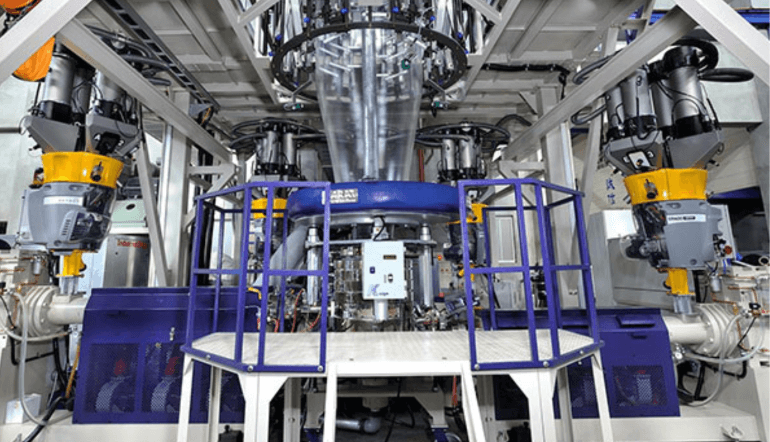

Optimizing Multilayer Blown Film : Key Factors & Advanced Machinery

Blown film technology has undergone significant advancements in recent years, resulting in the development of innovative multilayer blown film designs. These designs offer superior performance in terms of barrier properties, strength, and diversity compared to traditional monolayer films. However, achieving optimal performance requires careful consideration of several key factors during the design process. In this article, we'll explore the key considerations for optimal performance of innovative multilayer blown film designs.

Jumbo Steel: Leading the Next Generation of Straw Manufacturing

Jumbo Steel leads in straw-making machines, offering biodegradable straw solutions and tailored production equipment. Explore sustainable and efficient straw manufacturing technology today!

Leading the Way in Customized Extrusion Solutions: Sino-Alloy’s Highlight at K Show

For the first feature of the new year, we have an exclusive interview with Sino-Alloy Machinery, a company that has gained domestic and international attention in the extrusion field for its excellent technology and rich development experience. We discovered that Sino-Alloy's recent innovations align perfectly with the 2025 K Show theme and meet the latest industry trends.

JANDI'S : THE BRILLIANT EASY WAY OF BAG MAKING

Tackle modern production challenges with JANDI's JIT system for bag-making. Streamline blown film, printing, and bag-making processes while reducing waste, cutting costs, and supporting sustainability. Discover how automation transforms your bag-making operations!

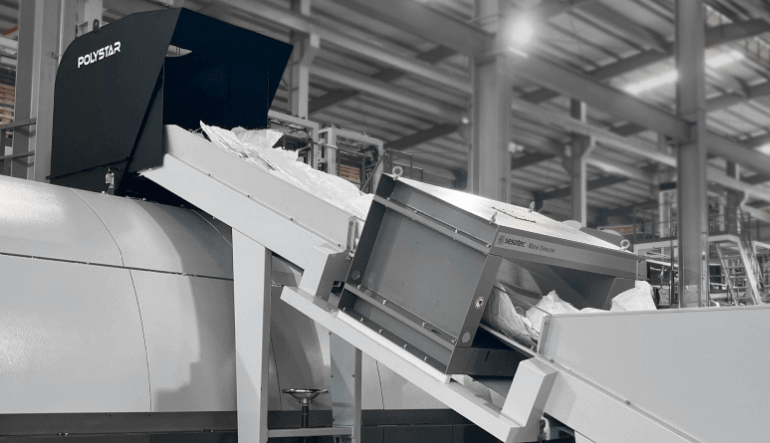

Looking for a High-Value Recycling Machine for 2025? Discover How the Repro-Flex Meets All Your Needs!

POLYSTAR’s Repro-Flex recycling machine produces high-quality, hole-free pellets. Unlike other systems, POLYSTAR’s technology delivers smooth, uniform pellets that enhance the strength and appearance of plastic films. These pellets ensure scratch-free, durable, and visually appealing products.

OEM with Italy Manufacturer for Better 3-layer Co-Extrusion Film Quality

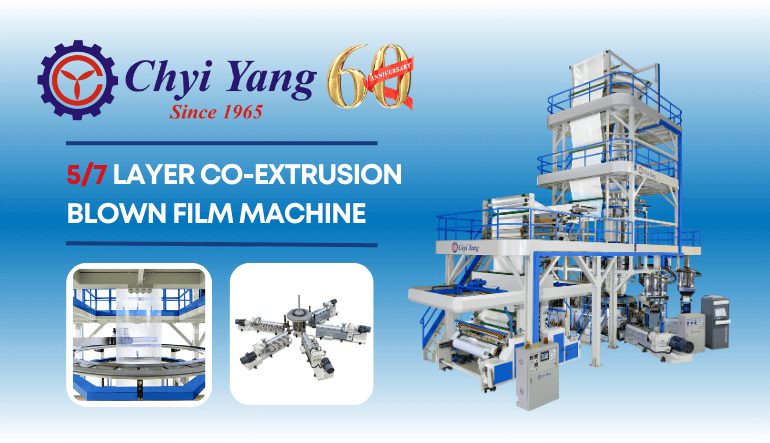

Chyi Yang showed one set 3-Layer Co-Extrusion Blown Film Machine in 2014 Taipeiplas exhibition. We cooperated with Italy SYCRO to produce main parts including IBC, 3-layer co-extrusion die, air ring, automatic width & thickness controller. The internal bubble control (IBC) is available for film cooling & increasing output. Film width is set up by touch screen instead of manual operation. According to the oil price increases & not stable, Chyi Yang uses Automatic Thickness & Width Control to control the difference range between ±5% to save resin cost. The air ring is up-and-down moveable in order to improve the cooling when you run high speed. There are 48 points in air ring to adjust the thickness automatically. The extruders are 65mm & 90mm & 65mm, equipped with motor 75HP & 100HP & 75HP. The max. film width is 1500mm & the capacity is max. 8.4tons per day.

Why KaoLu Proportional Valves Stand Out in Performance and Precision

An efficient fluid pressure and flow control system is key to ensuring the optimal performance and longevity of machinery. KaoLu's proportional pressure and flow control valves have emerged as a leading solution in the market, combining precision, durability, and energy efficiency. These valves are perfectly suited for applications requiring dynamic, rapid, and precise pressure and flow control.

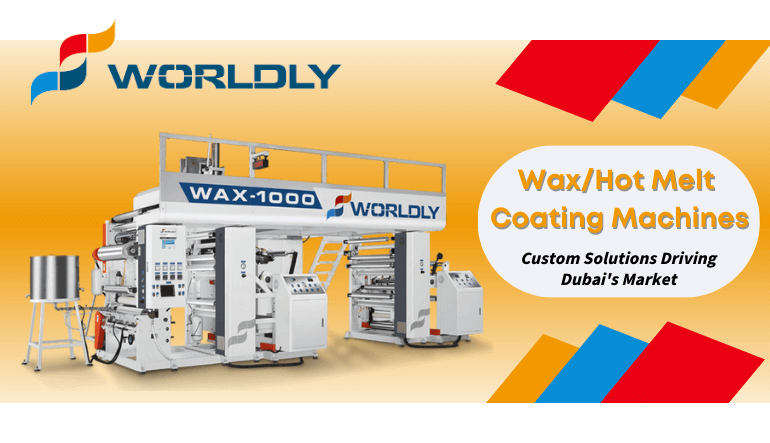

Worldly: Wax/Hot Melt Coating Machines and Custom Solutions Driving Dubai's Market

Since its founding, Worldly has provided a wide range of flexible packaging machines designed to exceed customer expectations. Worldly’s product lineup includes rotogravure printing machines, laminating machines, coating machines, and extrusion coating laminating machines. To stay competitive, manufacturers require solutions that deliver both high efficiency and versatility.

Shaping the Future of Plastic Recycling in the USA with POLYSTAR

The United States is putting more emphasis on sustainable practices. One area getting a lot of attention is plastic recycling, which is evolving rapidly in response to growing environmental awareness and shifting consumer habits. This industry is all about giving plastic waste a new life, from turning everyday items like used bottles, containers, and packaging into raw materials for new products to reducing the plastic piling up in landfills.

Hao Yu: Taiwan's Pride Leading the Global Market for Woven Bag Equipment

Founded in 1980, Hao Yu Precision Machinery Industrial Co., Ltd. has emerged as a leader in the global woven bag equipment manufacturing industry, renowned for its exceptional technology and professionalism. Hao Yu's product lineup includes complete plant equipment for PP/HDPE/PET woven bags and specialized machinery tailored for onion bags, jumbo bags, cement bags, tarpaulin, laminated woven bags (inner and outer), and geotextiles.

How Custom Coating and Laminating Machines Won Over Dubai's Market : A Success Story

Introduction In Dubai's fast-paced manufacturing sector, the need for advanced, adaptable machinery is growing rapidly. To stay competitive, manufacturers require machines that can deliver high efficiency and versatility. This blog explores how innovative custom coating and laminating machines have met these needs, leading to a notable success story in Dubai's market.

Case Studies in PVC Medical Tube Production: Real-World Examples of Success

In medical manufacturing, precision, efficiency, and reliability are paramount to producing life-saving devices. PVC Medical Tube Extrusion Lines are essential in manufacturing critical products like IV lines, catheters, and respiratory tubes. This article explores the key processes involved in PVC medical tube extrusion and provides real-world examples of successful implementations.

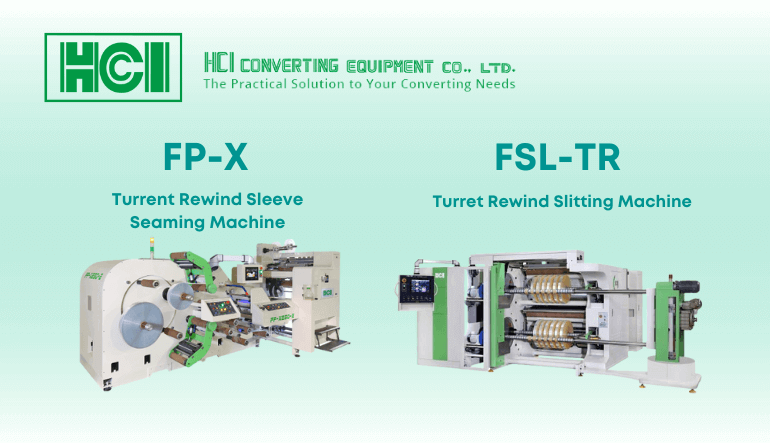

Driving the Circular Economy, Creating a Sustainable Future – HCI’s Green Commitment in Converting Machinery for Flexible Packaging

At HCI, we understand that industrial innovation and environmental protection can go hand in hand. We are committed to designing and manufacturing machinery that supports a circular economy, assisting our customers enhance production efficiency while reducing resource waste and moving towards sustainable development.

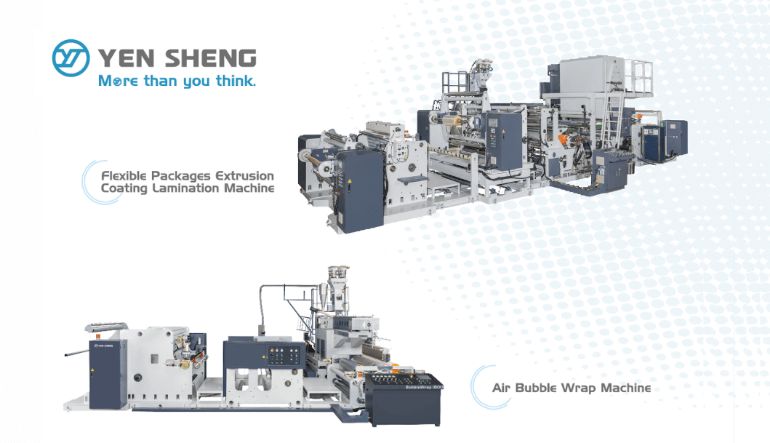

Explore YENSHENG’s Expertise at TaipeiPlas: Lamination, Bubble Film, and Beyond

At YEN-SHENG, we believe that consistent focus drives creativity and innovation. Since 1969, we have committed to delivering exceptional engineering services and integrating cutting-edge technologies into our machinery. We specialize in extrusion machinery, including the Extrusion Coating Lamination Machine, Air Bubble Film Machine, and Honeycomb Board Machine.

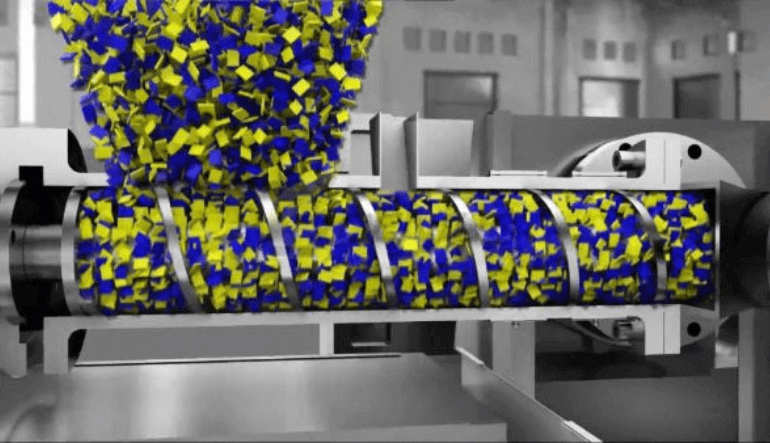

Comparing Feeding Methods for Plastic Recycling Equipment: Which One Suits Your Needs?

In the realm of plastic recycling, the way materials are fed into recycling equipment plays a pivotal role in determining overall efficiency and output. Whether handling thin films, bulky plastic waste, or powders, selecting the appropriate feeding method is essential for optimizing machine performance and maintaining consistent production. This article delves into the primary feeding methods used in plastic recycling equipment, highlighting their unique features and ideal applications.

Leading the Future of Green Manufacturing: CHYI YANG's Innovative 7-Layer Blown Film Solutions

With the rise of ESG sustainability goals and increasing global environmental awareness, the plastic film manufacturing industry faces a significant shift towards technological upgrades. Chyi Yang plastic machinery is at the forefront of innovation, launching its advanced 7-Layer Co-Extrusion High-Speed Blown Film Machine, which not only enhances production efficiency but also aligns with market demand for eco-friendly manufacturing.

POLYSTAR PP Raffia Recycling: An Eco-Friendly and Cost-Effective Approach for Manufacturers

PP raffia is a strong, durable, and cost-effective plastic widely used across various industries. However, improper disposal can lead to environmental harm. Fortunately, PP raffia is recyclable, offering manufacturers a sustainable solution to minimize their environmental impact while also benefiting economically.

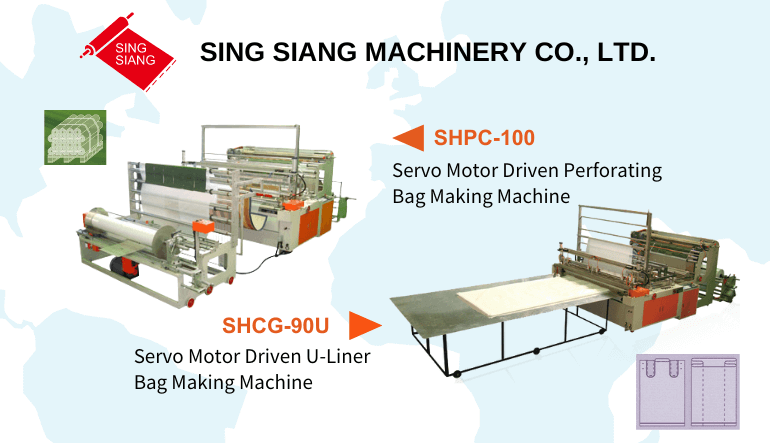

SING SIANG Always at the Forefront of Bag Making Machines Technology

SING SIANG Machinery Co., Ltd. (SSM) is established in 1975 in Taiwan, specialized in all kinds of bag making machines, always provides customers with the most comprehensive technological service. Based on more than 30 years of design and manufacturing experience, SSM is capable of design machines with practical performance for the customer, at a reasonable and competitive price.

BoReTech: Wastewater Treatment System Enabling Green Production for Plastic Recycling Facilities

Through the recycling of waste plastic, materials are reintroduced into the production cycle, achieving a “resource-product-waste-recycled resource” loop that prolongs plastic lifespan and effectively reduces the need for landfill and incineration. By recycling plastics, greenhouse gas emissions are decreased, contributing to the mitigation of climate change. As the plastic recycling industry advances, it paves the way for new technologies, plastic, and industries, promoting green innovation. However, with increased plastic recycling comes the critical task of addressing the wastewater treatment during the plastic recycling process.