Tung Yu Hydraulic Group Celebrates 40th Anniversary

Tung Yu Hydraulic Machinery Co., Ltd., established in 1983, is a major hydraulic machinery manufacturer in Taiwan. We are dedicated to the research and development of high-quality hydraulic mechanical equipment and provide customers with a wide range of molding solutions. Tung Yu has successfully built a wide customer base in the international market, and our products are sold to more than 70 countries around the world.

Key Point of Lithium-Ion Battery: Coating Technique

The rapid growth of the lithium-ion battery industry is driven by increased usage of 3C products and electric vehicles. Lithium-ion batteries offer high energy density, environmental friendliness, and a booming market exceeding $50 billion by 2025. Coating techniques are vital for uniform electrode slurry application, with slot die technology providing advanced solutions.

Tung Yu: Your One-Stop Service for Hydraulic Presses and Conveyor Belt Production Lines, Ranging from 5 Tons to 13,000 Tons.

Tung Yu offer a diverse range of products, spanning from 5-ton hydraulic presses to 13,000-ton conveyor belt production lines. Our services extend to comprehensive One-Stop Shopping for our customers. Our product lineup encompasses Compression Molding Machines, Rubber and Liquid Silicon Injection Molding Machines, Conveyor Belt Vulcanizing Machines, Tire Molding Machines, and Retreading and Solid Tire Molding Machines.

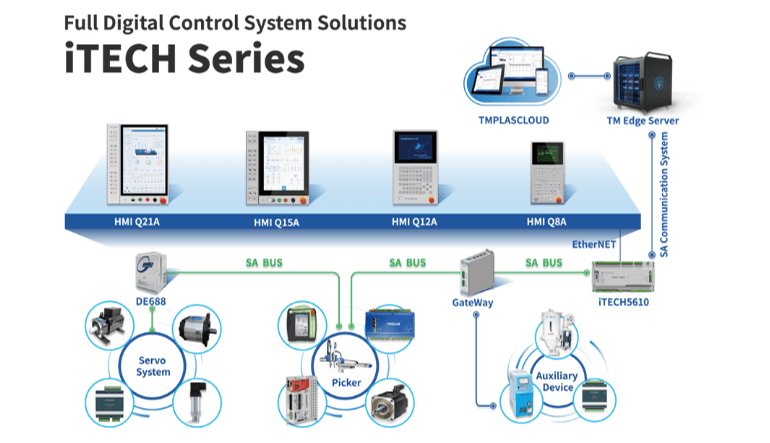

Building Techmation Digital Vision and Welcoming the 40th Anniversary of the Brand

2023 is a crucial year for Techmation Technology to connect the past and the future. At the end of its 30 year journey, Techmation Technology proposed a new concept of "establishing the Techmation Data Eye and Envisioning a Techmation Digital Vision". In the future, with decades of innovation accumulation, Techmation Technology will look forward to the digital development of the industry and promote its transformation and upgrading. Faced with the upcoming 40th anniversary of the brand, Techmation Technology is poised to showcase intelligent control systems, digital factory service platforms, and cutting-edge industry system solutions at this exhibition.

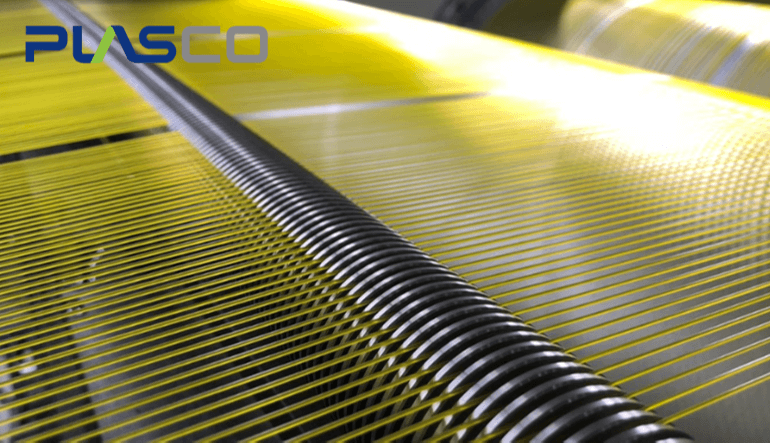

PLASCO: Key Features of Nylon Monofilament Extrusion Lines

Nylon monofilament is a versatile and strong material used in various applications such as fishing nets, dental floss, and strings for musical instruments.The production process for PA monofilament involves blending the materials in an extruder, followed by extrusion from a die head, drawing, and winding, all of which occur through the use of a nylon monofilament extrusion machine.

PLASCO: What Are The Trends for Monofilament Extrusion Line in 2023?

As a leading manufacturer in the monofilament yarn making machine industry, PLASCO would like to share the 4 main trends we expect to see in the development of monofilament yarn making machines in 2023.

Which Molding Machine is Best for Your Project?

The process to make rubber and silicone products is including materials preparation, mastication, mixing, preformer, cutting, calendaring, vulcanization and machining step. Each step needs specific equipment and technology to complete.TungYu provide machines with the best control on temperature and pressure which is the critical parameter in curing process.

Esleeve: Revolutionizing Shrink Sleeve Labeling with Cutting-Edge Solutions

In the fast-paced world of product packaging, staying ahead of the competition requires innovative solutions. Eversleeve Enterprise Co., Ltd. (Esleeve) is a leading global supplier of auto shrink sleeve labeling machines and accessories, dedicated to delivering state-of-the-art technology and exceptional service.

Efficient and Customized Blow Molding Solutions by CHEN WAY Machinery

Blow Molding is a widely used Plastic Molding method, and there is a high global demand for Plastic Molding. CHEN WAY Machinery Co., Ltd. specializes in manufacturing Plastic Blow Molding machines and has been in the industry for over 30 years since its establishment in 1990. They have successfully integrated research and development with manufacturing, and their products have been marketed in multiple countries worldwide. With rich experience in customized production, CHEN WAY can tailor machines 100% to clients' needs to meet their efficiency and effectiveness requirements in the production process.

What is TungYu's resolution for the next 40 years?

TungYu Hydraulic Machinery Co., Ltd. was founded in 1983 and has been devoted to the research and development, as well as manufacturing of hydraulic machinery for 40 years,at the moment TungYu is one of the leading enterprises in the global hydraulic machinery supply chain.

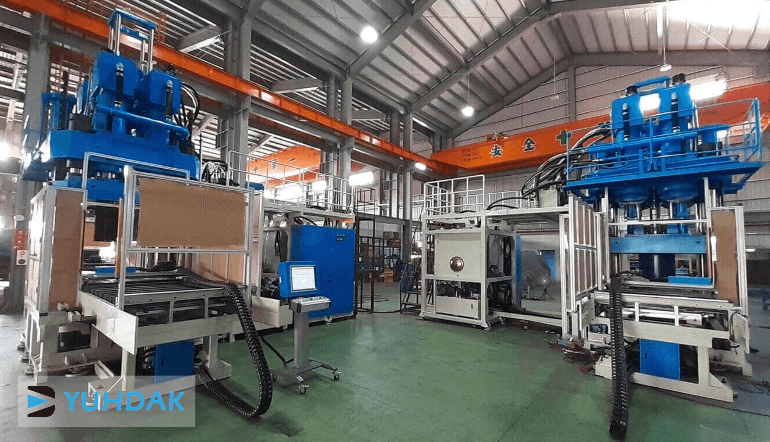

YUHDAK Enters Into the Detroit Automobile Glass Production Line Supply Chain | YUHDAK

After acquiring “automobile glass hemming machine” contract orders from the world’s largest automobile glass manufacturer, YUHDAK successfully broke into the American automobile supply chain. In joining the production line of an automobile glass giant based in Detroit, YUHDAK had to participate in a grueling selection process. It went up against European, American, and Japanese firms in the first round, Chinese firms in the second, and brands from Taiwan in the third, before ultimately being selected by the client.

In-mold Label, IML | XIANG IN

In mold labeling is an advanced method for decorating plastic containers in nearly ten years. It is suitable for the automated production products. You don’t need to do secondary processing if an injection machine or a blow molding machine equipped with the labeling system which can make a preprinted label permanently fused to the plastic part itself. It is not only reducing the production process but also increase the production capacity.