Transition to a Bio-Based Economy: Worley Takes on FEED for Avantium’s New Plant

Worley has been awarded the front-end engineering design (FEED) contract to develop Avantium’s flagship plant, supporting the transition to a bio-based economy for plastics. This plant will produce 100% plant-based FDCA (furandicarboxylic acid), a crucial component for various chemicals and plastics.

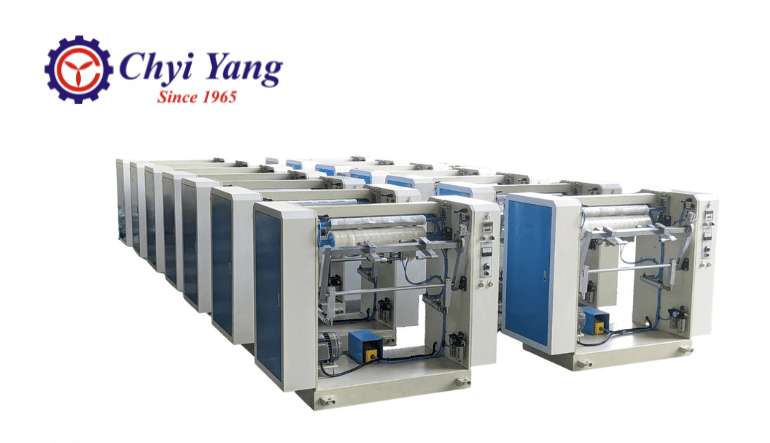

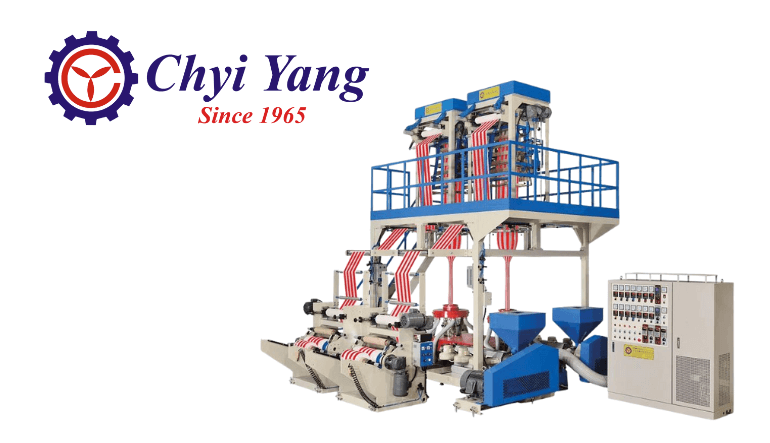

CHINAPLAS Exhibitor Interview: CHYI YANG PE Stretch Film/Cling Film Wrapping Machine

CHYI YANG, the products launched at the exhibition are PE stretch film/cleaning film wrapping machine: RW-1 Series and RW-2 Series. The fully automatic RW-1 series has a rewinding width of 300mm, a length of 30–300M, and a speed of 0–600 (M/Min). Increase work efficiency. The other is the RW-2 series, with a wrapping width of 200-550mm, a wrapping length of 30–1,000M, and a speed of 0–150 (M/Min). These two products can support industrial and food grade cleaning films, and are widely used and trusted.

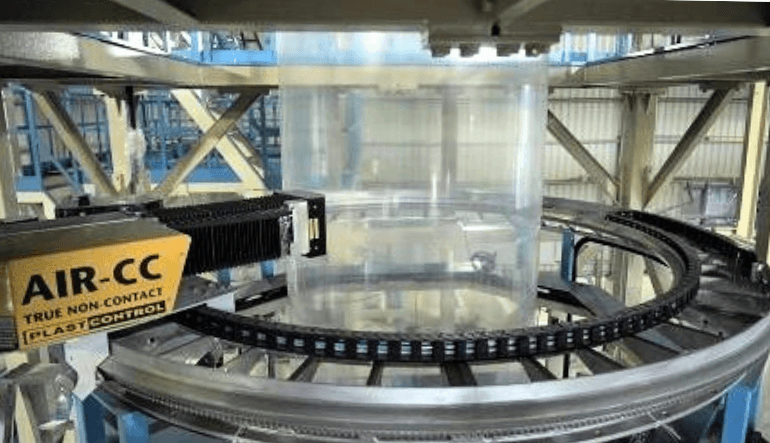

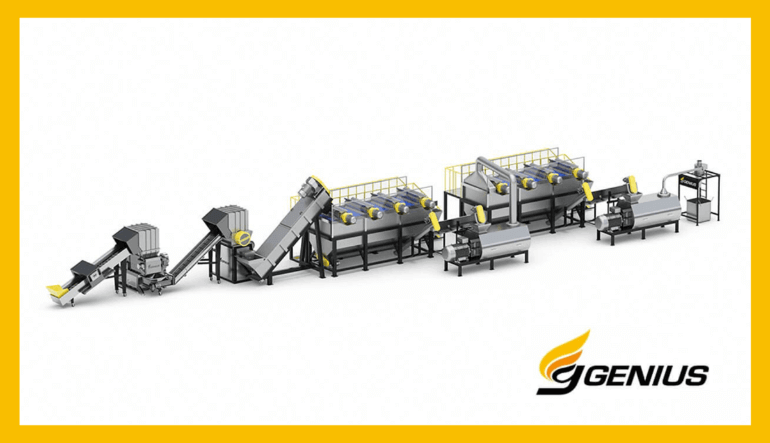

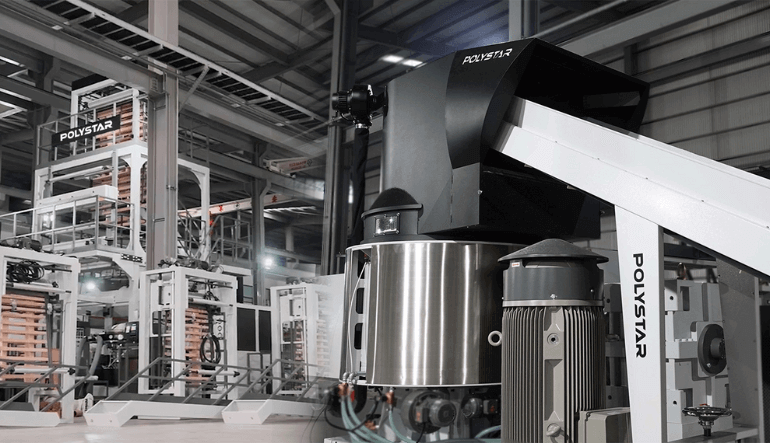

Plastic Pelletizer Comparison for In-house Plastic Film Recycling

In-house plastic film is usually clean and can be reprocessed right away without extra procedures. But what kind of recycling equipment you should invest in to make the best use of it? For in-house plastic film recycling, POLYSTAR has two recommended solutions: the Cutter-compactor Plastic Pelletizer, Repro-Flex, and the Air-cooled Plastic Pelletizer, Repro-Air. Both recycling machines can process HDPE, LDPE, and LLDPE clean post-industrial plastics like film, bags, T-shirt bag cut-offs, and edge-trim waste. However, Repro-Flex can deal with more kinds of plastics such as PP, PS, PA, etc. Let’s take a closer look at what they feature and their advantages, which are the main differences between them.

Eterlong's Evolution from Blown Film Dies Technical Skill to Comprehensive Blown Film Machines

For over 50 years of manufacturing experience in Blown Film Dies, Eterlong is dedicated to upgrade and optimize the design constantly to meet the market trend and the ever-changing technology.

Outstanding Quality Blown Film Machine Gets a Vietnam-listed Company's Favor

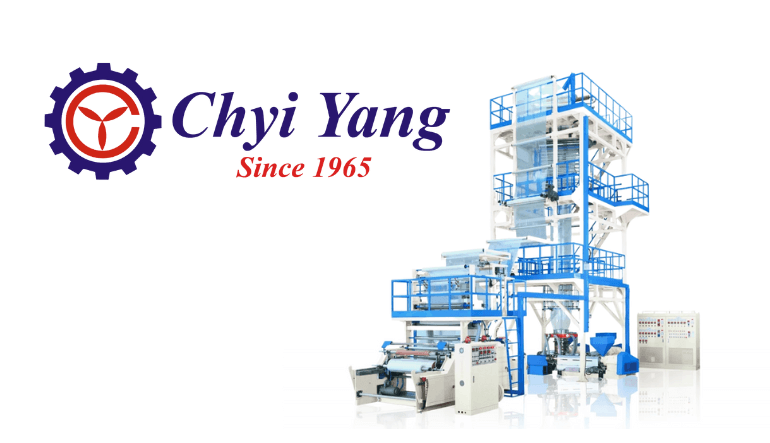

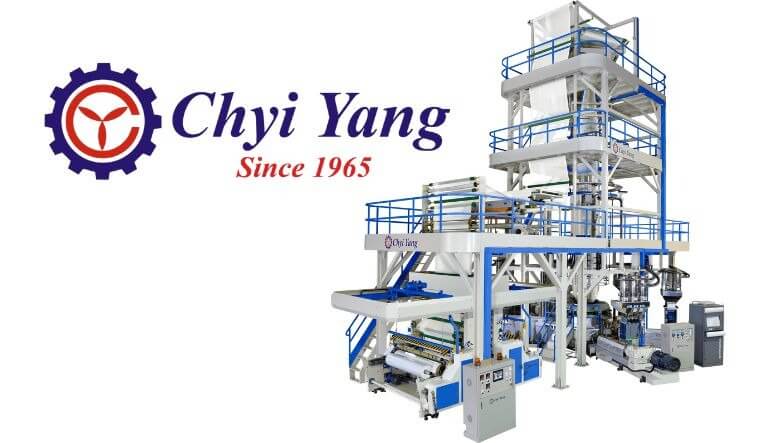

One of the listed companies in Vietnam purchased three sets of blown film machine from Chyi Yang 20 years ago. Afterward, in response to enlarged scope of the company and to reduce the cost, they turned to import equipment from China with lower price. However, the quality of film produced from China machine did not meet Japanese customer’s standard and up to 20 freight containers of products were returned in one transaction.

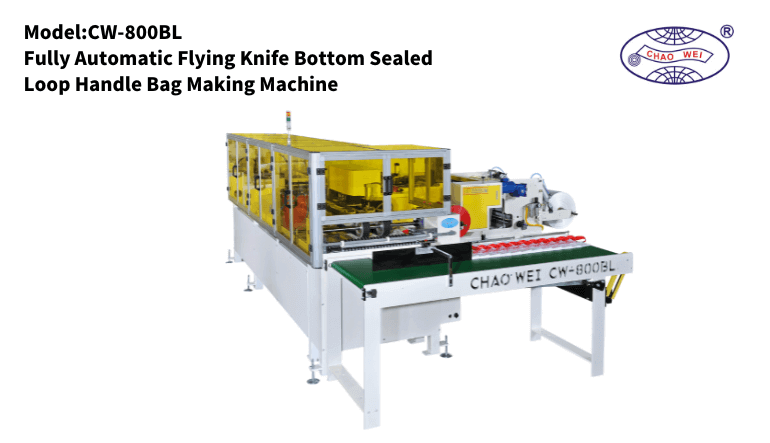

CHAO WEI: Bottom Sealed Bag Making Machine with In-line Folding Unit

Fully automatic bottom sealing bag making machine with in-line 3-foldings unit folds bags twice along their length and once along their width, achieving speeds up to 80 bags/min. Features include precise length control with YASKAWA servo motors, dual touch screens, German-made SICK photocell for printing alignment, and automatic stoppage for jams, film depletion, temperature anomalies, or print misalignment.

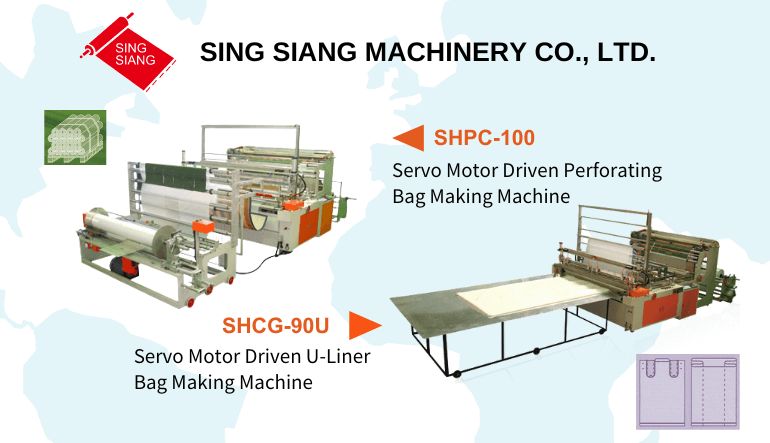

SING SIANG Always at the Forefront of Bag Making Machines Technology

SING SIANG Machinery Co., Ltd. (SSM) is established in 1975 in Taiwan, specialized in all kinds of bag making machines, always provides customers with the most comprehensive technological service. Based on more than 30 years of design and manufacturing experience, SSM is capable of design machines with practical performance for the customer, at a reasonable and competitive price.

Meet Your Needs for Stable Thickness, High Productivity & Multilayer Quality with CHYI YANG Blown Film Machine

The global ESG trend is forming, and corporate sustainability will become a "standard" for businesses. As the European Union takes the lead in announcing the 2030 carbon reduction target, countries follow suit, and the plastic film industry is also contributing to the trend of sustainable development.

YICHEEN: Multifunctional Slitting Machine – The Importance of Post-Processing in the Flexible (Plastic) Packaging Industry

Understanding the Principle of Operation To fully leverage post-processing equipment in the flexible (plastic) packaging industry, it is crucial to understand its working principles. The post-processing slitting machines in the flexible (plastic) packaging industry primarily deal with two main types of materials: 1. Plastic tape / 2. Plastic film.

Creating Business Opportunities with CLF's Customized Injection Molding Solutions

Deeply rooted in the Southeast Asian market, Chuan Lih Fa(CLF) – Taiwan's leading Injection Molding Machine manufacturer, known for high-tonnage and highly customized machines. In the following article, CLF will showcase their recent success stories and demonstrate how they integrate highly customized plastic injection technology into various industries, providing the best solutions for their customers.

From Waste to Resource: Pioneering Plastic Recycling Microfactory

In Phoenix, city officials are collaborating with Arizona State University to develop a pioneering circular plastic recycling microfactory. This initiative aims to create a replicable model that can be implemented across the country and even internationally. The project is associated with Precious Plastic, a global effort originating in the Netherlands, which provides communities with guidance, physical blueprints, and business models to start grassroots plastic recycling programs.

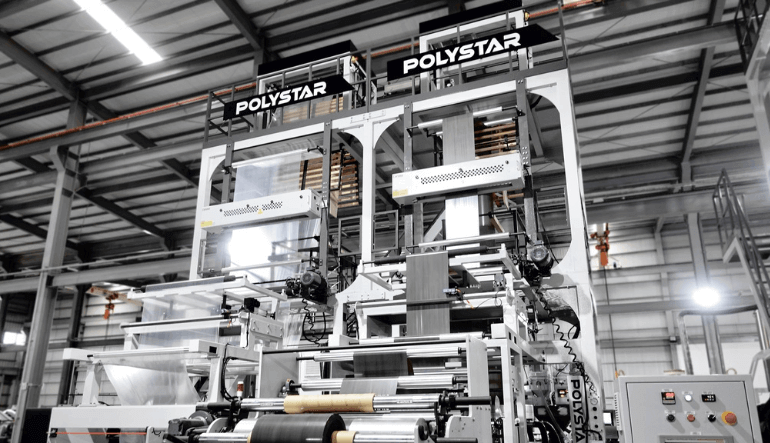

Optimized Blown Film Technology: Keys to Sustainable Packaging

Eco-friendly packaging is a necessity more than a trend, for both environmental and economic sustainability today. As one of the main carriers of packaging film production, blown film extrusion technology must keep evolving to meet the market requirements. POLYSTAR's blown film extruders are designed to be operationally stable and easy to use. Additionally, by optimizing extrusion screws and die heads, our machines empower manufacturers to adopt sustainable materials like recycled pellets, and CaCo3. Let’s take a closer look into how POLYSTAR develops its blown film extrusion machine technology to better contribute to eco-friendly packaging!

Do You Know the Invisible Champion Who Can Assist You Enter into the Cling Film/Wrapping Film Market with Ease?

How do we make PE cling film that is non-toxic, breathable, and easy to tear and break? Ask Chyi Yang, the company that provides a complete plant solution that enables beginning manufacturers to enter the PE cling film/wrapping film market with just one machine, allowing them to cope with the unpredictable market environment easily.

Super High Speed HDPE Capacity Blown Film Machine in Less Space

Chyi Yang showed one set “Two Stripes & Two dies Co-Extrusion Blown Film Machine” in Andina-Pack 2015 Colombia exhibition. This machine is equipped with two dies & two extruders to produce two stripes T-shirt bags for market using. The two 45mm extruders provide two dies to have 2-line film rolls at one time. Forced feeding extruders offer you bigger capacity, the max. capacity is 140kgs/hr. for 550mm film width at 20micron film thickness. You can get max. 70kgs/hr. from each winder, and max. 140kgs/hr. from two winders.

CHAO WEI: Bottom Sealed Loop Handle Bag Making Machine

CW-BL is for bottom sealed loop handle bags at maximum speed 50 bags/min.

Essential Types of Plastic Recycling Machines for Efficient Waste Management

Plastic recycling is essential for addressing the waste crisis and reducing environmental impact. Beyond waste reduction and resource conservation, a significant advantage is the substantial decrease in carbon emissions achieved by diverting plastic from landfills and incineration. Recycling processes inherently involve lower energy usage, resulting in decreased carbon emissions. To enhance efficiency and maximize environmental benefits, integrating advanced technologies like plastic recycling machines, including Plastic Extruders, Shredders and Granulators, Plastic washing Lines, and Plastic Pelletizers are crucial. These mechanized systems automate and streamline the recycling process, making it more economically viable and scalable.

How Can High Quality be Produced Consistently out of Complex Formulations?

The blown film market is evolving in an increasingly fast pace to meet the highly diversified, large-volume and variable material requirements of industries and emerging applications. Bag manufacturers and packaging material producers must use blown film machines with hardness, corrosion resistance, and durability to achieve consistently high yields while maintaining quality. More important goal is meeting the demands in film processing with complex characteristics such as those for agricultural films, cover films, laminated films, grain and dry food packaging, medical packaging and other critical packaging.

Congratulations to CHYI YANG for Being Awarded the 8th Dun & Bradstreet SME Elite Award

According to the data analysis and evaluation of Dun & Bradstreet's global database, it was selected as the Top 1000 Elite Enterprises in 2021 the 8th Dun & Bradstreet SME Elite Award.

JANDI'S: Pioneering Eco-Friendly and High-Efficiency Bag

JANDI'S is a leading supplier of high-quality equipment for the plastic film and bag manufacturing industry, specializing in Blown Film Machines, Bag Making Machine. Our commitment to innovation and sustainability is evident in our continuous efforts to develop machines that cater to the evolving needs of eco-friendly production.

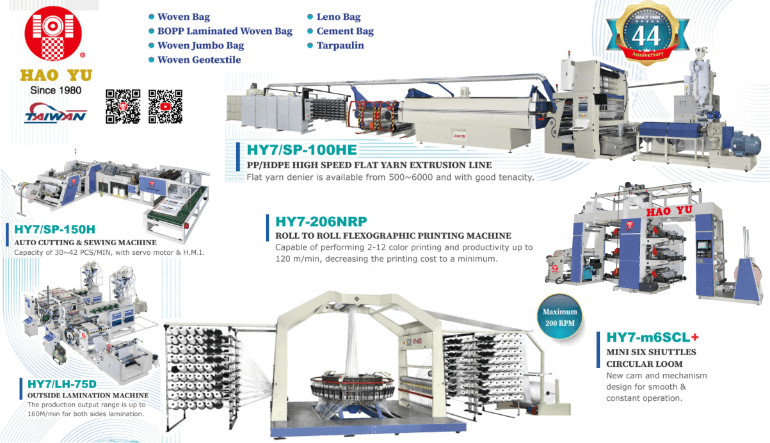

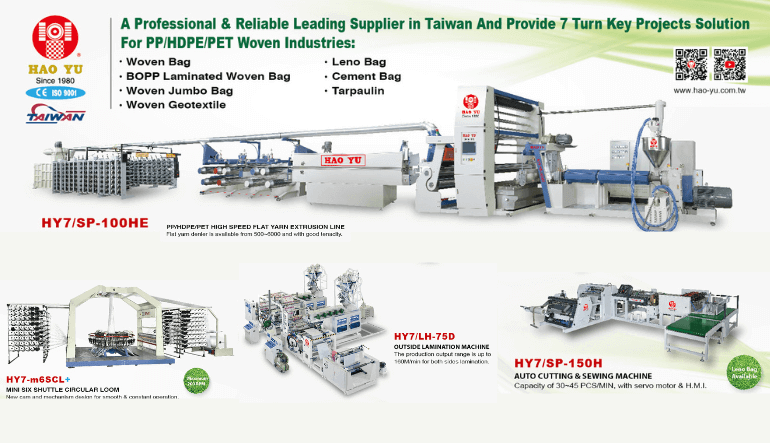

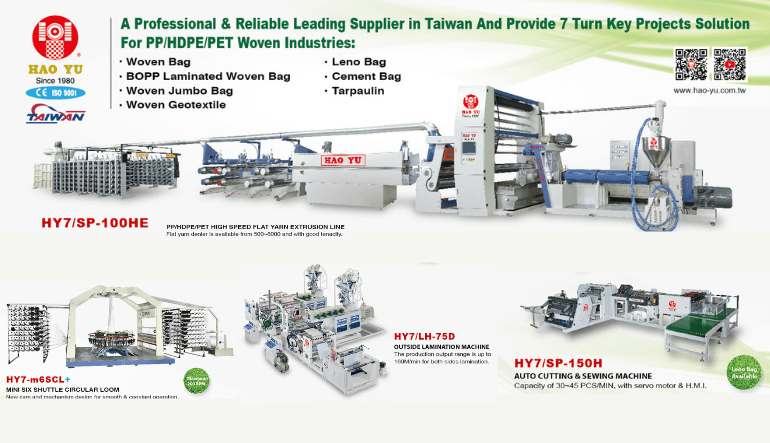

HAO YU: A Professional & Reliable Leading Supplier in Taiwan Provide 7 Turn Key Projects Solution For Plastic Woven Industries.

HAO YU Precision Machinery Industry Co., Ltd. is a one of the most skillful & experienced manufacturers of PP and HDPE and PET woven bag machinery and whole-plant equipment in Taiwan since 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence. Our objective is to enhance our present machinery and develop new models that improve the efficiency, product quality and profitability for our customers.

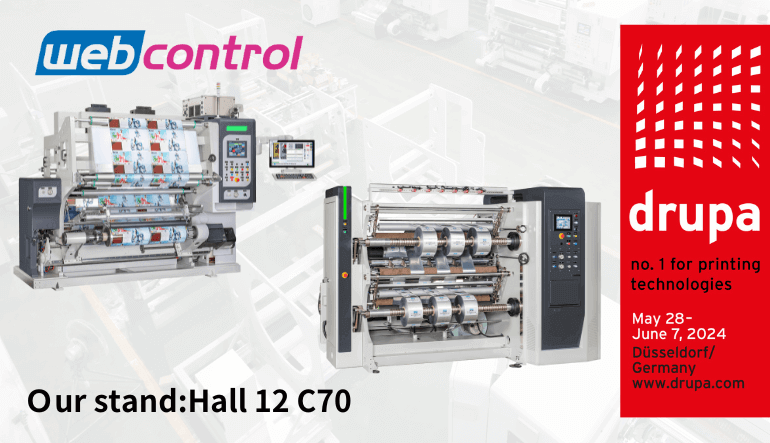

Experience Precision and Efficiency: Visit WEBCONTROL at Drupa 2024, Hall 12 C70!

Drupa's coming! We are already excited to show our excellent machines at our stand Hall 12 C70. Join us and see how Webcontrol can help you save time, reduce waste and achieve efficient production!

MING JILEE: Turnkey for Air Bubble / EPE Foam Converting Production

MING JILEE provides the all kind of converting machine for air bubble and EPE foam material. For the different application, we can cut the material into envelope, bag, sheet, hole punching, coreless roll. Latest model MGA-47P-1000 is 100% Paper Bubble Mailer Making machine, we design the heavy duty bubble embossing station to make the bubble shape paper in-line from mailer making machine.

Super Provider of Essential Blown Film Line for the "Unmanned Factory"

Global manufacturing has been struggling in recent years to address the labour shortage. The wave of automation has arrived quickly due to the significant impact of global pandemic, wars, and other "black swan" effects - and the market's industrial upgrade is about to occur. Right now, it appears that there is a major global supplier of film-blowing technology who has been quietly offering automated equipment solutions for years, aiding in the establishment of "unmanned factories," and strongly supporting these film manufacturers to successfully pass the "post-pandemic era." Chyi Yang Industrial Co. is the super provider of this key blown film line solution.

POLYSTAR Recycling Machines Turn Waste into Profit

In the first quarter of 2024, POLYSTAR traveled to various countries worldwide for installations, maintenance, and exhibitions. We had the pleasure of meeting one of our biggest customers in the US. In this article, we'll take you through their successful journey of integrating our plastic recycling technologies and achieving success in the industry. If you're interested in our plastic recycling machines, be sure to catch us at these upcoming exhibitions for our innovative plastic recycling solutions

TAIWAN KINKI: Dual Expertise in Business and Technology, Standing Out in the Vertical Injection Molding Industry with Excellence in Quality and Flexible Services

Taiwan Kinki Machinery (TKC) has established itself at the top of the vertical injection moulding industry after more than four decades of persistence, overcoming challenges under Mr Wu's command, and impeccable teamwork. Their astonishing achievements can be found in each machine they make, which is capable of extreme precision and efficiency, but more importantly, in their excellent services that successfully satisfy buyers’ demands.

The Multilayer Film Boom: Why Companies are Investing

International Plastics News for Asia | Chi-Chuan Cheng The Multi-Layer Co-Extrusion Film Blowing Machine plays a vital role in modern plastic production with its benefits of high efficiency, automation, precision, and energy efficiency. It finds applications not only in food, building materials, and agriculture but also in fields like medicine, chemical, and electronics.

Quality Triumphs Cost ── Lessons from a Leading Vietnamese Industrial Player CHYI YANG's Customer-Centric Approach

International Plastics News for Asia | Chi-Chuan Cheng The crucial consideration for manufacturers is whether to cut costs or enhance value. There is a well-established plastic film producer located in Hanoi, Vietnam, which a few years ago purchased blown film machines from the renowned quality-driven company, Chyi Yang. However, due to price considerations, the factory later shifted to purchasing low-cost multilayer blown film machines manufactured in China, temporarily expanding its production capacity. Despite momentarily stepping back from the price competition, Chyi Yang remains steadfast in its commitment to quality-driven development, continuously innovating and advancing with the introduction of various styles of 5-layer / 7-layer co-extrusion blown film machines.

Path to a Greener Tomorrow── CHYI YANG's CFV Solutions of Precision and Sustainability

Global environmental awareness has prompted the manufacturing industry to transition towards green production. The need for "carbon reduction" in the CFV stages has led the global blown film manufacturing industry to pursue sustainable development solutions. Chyi Yang's 5-layer / 7-layer co-extrusion blown film machines have become a key player in today's green supply chain due to their three key advantages: "Big Data Analysis," "Precision Formulation and Calculation Functions," and "Recycled Waste Technology Innovations" in their multi-layer blown film machines. The international blown film manufacturing market also recognizes the indispensability of Chyi Yang in the trend of carbon reduction.

2024 PRM Spotlight Plan: Monthly Success Stories of Taiwanese Suppliers

In this article, we delve into the "Spotlight" plan, a monthly showcase that highlights the exemplary efforts of Taiwanese suppliers in tailoring solutions to meet customer needs, fostering innovation, and driving the industry forward. Though the export data for Taiwan machinery decreases in 2023 due to the economic recession, the excellent suppliers must be seen. And that's why PRM, as a pioneer media in the Plastic and Rubber industry, devoted itself to promoting Taiwanese brands.

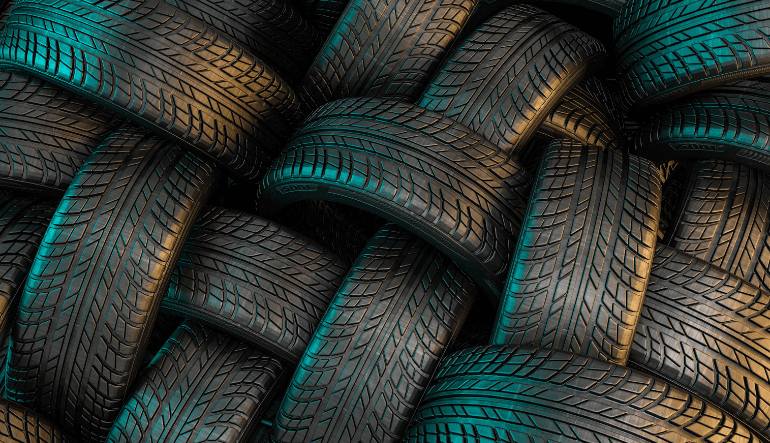

Advanced Technologies Could Process 20 Percent of U.K.’s Waste Tires

Norwegian rubber waste recycler Wastefront is set to open a $120 million plant in Sunderland, England, either late in 2024 or early 2025. The plant will utilize pyrolysis to convert end-of-life tires into tire-derived oil (TDO), which will then be refined into various combustion fuels, including diesel. Wastefront claims that the TDO produced will be cleaner than fossil diesel and cost-competitive, depending on the grade. It is expected to be cheaper than hydrotreated vegetable oil and similar biofuels.

HAO YU: Pioneering Excellence in Woven Bag Machinery Since 1980

HAO YU Precision Machinery Industry Co., Ltd. is a one of the skillful & experienced manufacturers of PP and HDPE woven bag machinery and whole-plant equipment in Taiwan since 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence.

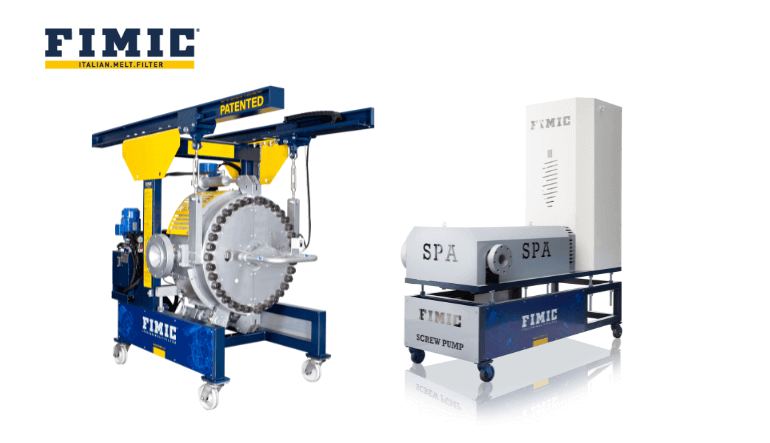

FIMIC Innovations in Automatic Filtration

Recycling is a game where size matters. Nowadays recyclers need to reach a higher hourly production capacity with efficiency and simplicity, they required right applications for high-throughput recycling lines. FIMIC has been working many years now on improving its filtration technologies in order to meet and satisfy the needs (quality, characteristics) of recyclers, and at the same time facing the challenges of recycling post-consumer and post-industrial plastics.

ETERLONG: Your All-In-One Solution for Blown Film Machines

ETERLONG – A merger with the leading Blown Film Die manufacturer former brand HSIN LONG. Continuation of HL spirit and experiences, in addition, ETERLONG have advanced production facilities and acquire IoT (Internet of Things) intelligent equipment to expand production capacity. We are dedicated to create All-in-One to deliver great service to make customers simple choices, they can purchase not only individual components but also complete Blown Film Machines, all from ETERLONG.

POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

HAO YU: Pioneering Excellence in Woven Bag Machinery Since 1980

HAO YU Precision Machinery Industry Co., Ltd. is a one of the skillful & experienced manufacturers of PP and HDPE woven bag machinery and whole-plant equipment in Taiwan since 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence.

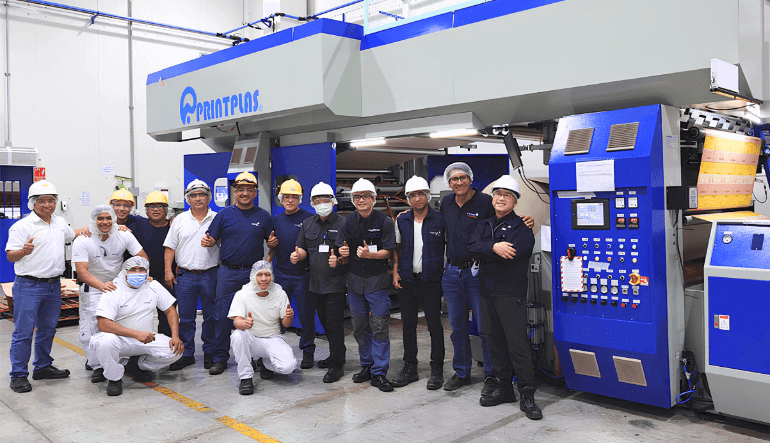

PRINTPLAS: PRECISION, NO BLUR YOUR BEST PARTNER IN PRINTING BUSINESS!

Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan. With skilled workers and machine R&D department, we are keeping our efforts to providing precise, stable, high-speed printing machines for our users.