Plastics & Rubber Machinery Videos

With PRM professional matching services, we labeled 15 Machinery Categories and more than 600 videos, for you to conveniently find a supplier that best suits your business.

ALL STYLES

AUXILIARY EQUIPMENT AND INTEGRATED AUTOMATION

BLOW MOLDING MACHINES

EXTRUDERS AND EXTRUSION LINES

FINISHED/SEMI-FINISHED PRODUCTS

INJECTION MOLDING MACHINES

MOLDS AND DIES

PACKAGING MACHINERY

PARTS AND COMPONENTS

PLASTIC CONVERTING MACHINES

PLASTIC RECYCLING & MATERIAL PROCESSING MACHINERY

PRINTING MACHINERY

RAW MATERIALS & ADDITIVES

RUBBER PROCESSING MACHINERY

SHOE MAKING MACHINERY

THERMOFORMING MACHINES

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC)

[TAIWAN KINKI LINES OF BUSINESS]

Production of vertical plastic injection molding machines.

Design of automatic injection molding machinery.

Turn-key plants for accessories and peripherals for injection machinery.

Injection mold design and manufacturing.

Electrodeposition, powder coating, baking enamel, and leather treatment.

Agency of the vertical injection machine and Zinc alloy coating.

[APPLICATIONS]

Especially suitable to manufacture Automobile Parts

[TAIWAN KINKI (TKC) BACKGROUND]

TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing.

The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

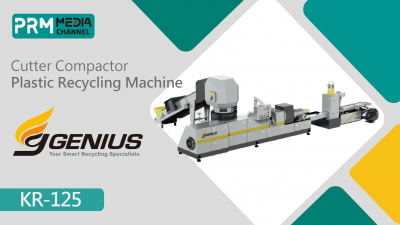

Machinery in the Video: GENIUS KRIEGER Series - KR-125 Cutter Compactor Recycling Machine

[VIDEO HIGHLIGHTS]

0:00 Plastic Recycling Machine - KR-125

0:28 Belt Conveyor

0:41 Cutter Compactor

1:00 Main Extruder

1:11 User-Friendly Control Panel

1:26 Dual-Piston Filter

1:36 Die-Face Cutting Pelletizing

[KEY FEATURES ]

Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc.

Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials.

High torque precision gearbox. Low noise and steady operation.

Die-face pelletizing is expected to reduce manpower costs.

The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation.

SAVE cost, energy, and time.

The single extruder is suitable for clean materials such as injection leftovers and production waste.

[COST SAVING]

Saves energy cost up to 20%

Reduces labor cost as only 1~2 operators are needed to operate the whole plant.

[SUPERIOR FEATURES]

/Compacting & feeding/

The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity.

/Multiple Cooling/

Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature.

/Flexible Customization/

GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.

Two Platen Injection Molding Machine 600TPIIR 3D animation from CLF.

CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance.

【HIGHLIGHTS OF THE MACHINE】

Clamping Force 1800~4000 TONS

Unique two-platen design for clamping mechanism exhibits exceptionally high-speed clamping feature.

Clamping force, mold opening stroke, and distance between tie bars are easy to customize.

Quick and accurate mold adjustment makes the machine suitable for small lot flexible production.

Uniform force distribution on mold ensures the high accuracy of the product.

Uniform tension force on tie bars for the dramatic increase of service life.

Simplified construction with no wearing problem on toggle clamp.

Rigid machine structure, minimum deformation, and consistent product accuracy.

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, World Steel is dedicated to making technological innovations and manufacturing packaging machines. The company has one of the best engineering crews in the industry to provide total solutions which include design, customization, and development.

If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self-adhesive bags, handle bags, sandwich bags, or more, then World Steel is one of the best choices for you.

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU.

For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance,

PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap.

Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S

SUITABLE MATERIAL: HDPE / LDPE / LLDPE

APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on.

FILM THICKNESS: 0.010-0.15 mm

FILM WIDTH RANGE: 1200 mm

FILM OUTPUT: 90-140 kgs/hr

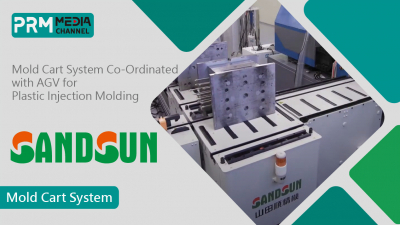

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer.

Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world.

Features of die/mold cart system :

Shorten the operation time of mold change.

Auto position checking of mold changer moving.

Automatically check the stroke of mold open, arrival, and positioning in the process of moving.

Device for preventing mold sliding.

Die / Mold Cart System co-ordinate with AGV :

This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals.

#

SANDSUN

Die Cart System

Mold Cart System

AGC

Automated Guided Vehicle

Fourth Industrial Revolution

Industry 4.0

PRM Media Channel

Hizli Kalip Degistirme Sistemleri

Enjeksiyon Makinesi Kalip Degistirme

MACHINERY LINE IN THE VIDEO: Bottle-to-Bottle Grade PET Bottle Washing Line from BoReTech.

The line is mainly used for PET bottle-to-bottle projects (FDA Approval), which recycles post-consumer PET bottles into rPET flakes. The regenerative PET flakes conform to the quality index requirements of downstream food packaging and are used for bottle blowing and packaging which can directly contact food after pelletizing and SSP processes in the late stage.

HIGHLIGHTS

Solutions for diversification of input PET bottle bales.

Automatic de-baling technology, reduces labor, a strong bale breaking ability for high-density PET bottle bales.

Patent technology for PVC label removal.

Patented Pre-washing and hot washing process to ensure the cleanliness of rPET flakes.

Integrated technology and capability for automatic sorting machine and PET bottle recycling line.

The hot washing process reduces impurities content to achieve food-grade index.

Stable and reliable quality of rPET flakes, online inspection to ensure the stability of rPET flakes.

Completed online water recycling treatment system for pre-washing, hot-washing, and rinsing.

Low operation breakdown, production management guidance service for the customers.

FOOD GRADE PET BOTTLE RECYCLING PROCESS

De-baling➜Metal Removal➜Label Removal➜Metal Removal➜Bottle Pre-washing➜Optical Bottle Sorting➜Manual Sorting➜Crushing➜Dust Removal➜FlotationHot washing➜Friction Washing➜Rinsing➜Flushing Washing➜Drying➜Dust Removal➜Optical Flakes Sorting➜Blending➜Online Inspection➜Packing

FOLLOW PRM ON:

PRM YouTube:https://www.youtube.com/c/PRMTaiwan

PRM Facebook: https://www.facebook.com/PRMMediaChannel

PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

#BoReTech #PRMMediaChannel #PETrecycling #PETwashingLine #BottleToBottleRecycling #PRMTAIWAN #Plastics #Rubber #Industry #Internationalmarket #Export #machinery #PET #PETbottle #Recycling

BoReTech has been a specialized manufacturer focusing on the customized R&D for PET recycling production since 1989. Moreover, the company also has more than 15 years of manufacturing experience. BoReTech provides a total solution of the plastics recycling system, polyester staple fiber production, and many more.

In the video, you will find the on-site machine introduction of :

PET Bottle Recycling System

Process for Food Grade Flakes

Know PRM Media Channel more on:

PRM YouTube: https://www.youtube.com/c/PRMTaiwan

PRM Facebook: https://www.facebook.com/PRMMediaChannel

PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

Inquiry and More Info: https://bit.ly/3hVGAvO

Introducing the Film/Bags Waste Plastic Recycling Machine from one of the pioneering plastic recycling machinery and film extruder manufacturers in Taiwan, KANG CHYAU.

Please click the link above for more information and/or inquiry, which will direct you to the manufacturer. For any assistance, PRM will be more than happy to assist. Contact us through our social media platforms or leave a comment below. Then we will reply and contact you asap.

Machinery in the video: Film/Bags Waste Plastic Recycling Machine

Model No: KCR-85

Output:80-120 kgs/hr

Screw Diameter: Ø 85mm Single Dega Sification

Suitable Materials: HDPE/LDPE/LLDPE

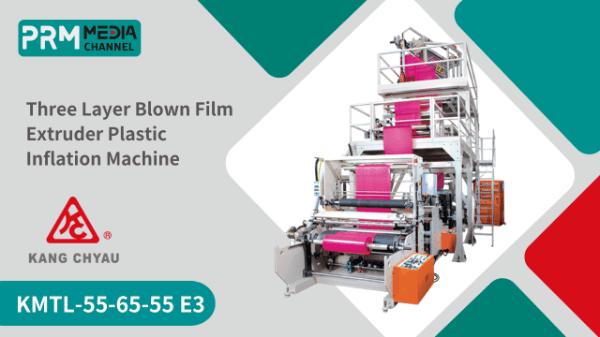

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap.

Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3

Film Width: 500-1800 mm

Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm

Suitable Materials: HDPE/LDPE/LLDPE/mLDPE

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN

[DESCRIPTION of the Machine]

⚡️Special for two lines perforating coreless bottom and star sealing bags on roll.

⚡️In-line triangle folding device for star sealing bags.

⚡️E.P.C. (Edge Position Control) for the film at correct position.

⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption.

⚡️Bag length & production speed can be changed easily from touch screen.

⚡️German made photocell-SICK for accurate printing mark.

⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees.

⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll.

⚡️Two lines automatic roll changing system.

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine

GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more.

We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.