Plastics & Rubber Machinery Videos

With PRM professional matching services, we labeled 15 Machinery Categories and more than 600 videos, for you to conveniently find a supplier that best suits your business.

ALL STYLES

AUXILIARY EQUIPMENT AND INTEGRATED AUTOMATION

BLOW MOLDING MACHINES

EXTRUDERS AND EXTRUSION LINES

FINISHED/SEMI-FINISHED PRODUCTS

INJECTION MOLDING MACHINES

MOLDS AND DIES

PACKAGING MACHINERY

PARTS AND COMPONENTS

PLASTIC CONVERTING MACHINES

PLASTIC RECYCLING & MATERIAL PROCESSING MACHINERY

PRINTING MACHINERY

RAW MATERIALS & ADDITIVES

RUBBER PROCESSING MACHINERY

SHOE MAKING MACHINERY

THERMOFORMING MACHINES

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, they are dedicated to making technological innovations and manufacturing packaging machines.

World Steel on PRM: https://www.prm-taiwan.com/shorturl/Qrm7p5Qg

Product Description

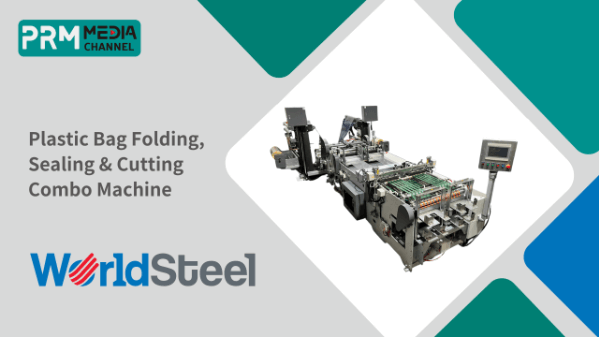

The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation.

Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design.

For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc.

Applications for Electronic Pressure Regulators

Spraying/ Painting

Air Blowing

Leak Testing

Filling Pressure

Artificial Heart

Laser Cutting

FAQ session – Proportional Electronic/Digital Pressure Regulators

What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge?

They are the same products with different names.

Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc.

Is the pressure regulator resistant to dirt?

No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm.

Any restriction on mounting orientation?

Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag.

Knowledge Base

How Does a Proportional Pressure Regulator Work?

A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control.

Uses of Regulators

Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications.

The Working Process:

Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static.

When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal.

Please check our video on: GennDih Enterprise. Co. Ltd

TAIWAN KINKI(TKC) is pioneer of Vertical Injection Molding Machines for Auto Industry, we were the first in the world to design and manufacture the 1st all-electric vertical injection molding machine for Taiwan and China. TKC works with a wide range of plastic injection materials and molded parts.

【All-Electric Vertical Injection Molding Machine Features】

Low Noise:All process-relevant movements (injection, mold open/close) are executed via electric motors, resulting in quieter and less noisy operation.

High Efficacy:The electric unit is digitally controlled so that the mechanical operation is highly repeatable and precise, and the electrical drive enables the parallel movement of the machine, so the process is faster and more efficient.

Save Water:Fewer components and oil need to be preheated than hydraulic injection machines, thus saving on cooling water usage.

Power Green Energy:No hydraulic system is used, and energy is only used during machine movement, so it can save more energy and achieve power green energy.

Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturer of PP/PE/PET woven bag machinery and whole-plant equipment. Since its establishment in 1980, HAO YU has been dedicated to the research and development of high performance machinery. Our dedication to continuous research and development is the reason for the excellence of HAO YU machines. Our objective is to enhance our present machinery and develop new models that improve the efficiency, product quality and profitability for our customers.

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

Specializes in bag making machine, Dah Bah Machinery Industrial Inc. is the pre-eminent manufacturer of high-quality bag making machine, as well as a complete range of other converting equipment for bag making machine.

RE-PLAST EXTRUDER CORP. IPF JAPAN 2023 FAIR DEMO MACHINE: RTU

Going beyone the traditional fixed type designs, effectively achieving noise reduction and dust prevention.

Production speed up to 250 pcs/minute 15,000 pcs/hour.

Paper Bubble Mailer Making Machine, MGA-47P-1000

Learn More:https://www.mingjilee.com/tw/product/...

MING JILEE: PP Extrusion Line and Bag Converting Machine Since 1987

Made In Taiwan, Best Quality and Global Support

Website: https://www.mingjilee.com/

E-mail: [email protected]

Whatsapp: +886 934 081 955

Complete Address: No.76-8, Ming-Ho, Ming-Ho Vil., Shan-Shang Dist., Tainan City, 74342, Taiwan

ISOTHANE Bio TPU

Sustainable bioplastics derived from natural plants, Make life more energy efficient and make the world a better place to live.

Our PET / PLA Crystallizer is a closed-loop heating system continuously to re-crystallize PET amorphous resin and covert it into crystalline state.

FEATURES

The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time.

YANN BANG Crystallized Hopper Dryer is the best choice for PET users.

1. SAVE COST. With YANN BANG's patented drying technology,the crystallized hopper dryer mixes the resin evenly while drying and shortens the drying time.

2. PREVENT BRIDGE MAKING. When drying oily,sticky,abnormal shaped resin,it is easy to have the bridge making.To use the crystallized hopper dryer can prevent the bridge making effectively.

3. NUMEROUS MIXERS AVAILABLE. Different kinds of unique mixers to suit for your special needs.