Source:PRINTPLAS

Video Description

- The central impression drum surface precise grind and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transport and precisely printed.

- 80mm thick cast metal plate frame provide a very steady, vibration free foundation for the printing work.

- Servo motors equipped for main drive / in-feed /out-feed / unwind and rewind, provide a smooth motion control for constant tension for film.

- Servo motors driven auto impression setting for each printing station with memory pack.

- Anilox sleeve and plate sleeve system is quick change side insert type.

- Turret type auto splicing for unwind and rewind is non-stop to change the roll.

- Equipped with internet accessible control system for remote diagnoses of programming and electronic components.

【Company Introduction】

Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan.

With skill workers and machine R&D department, we are keeping our effort for providing precise, stable, high speed printing machine for our users.

Featured Videos

-

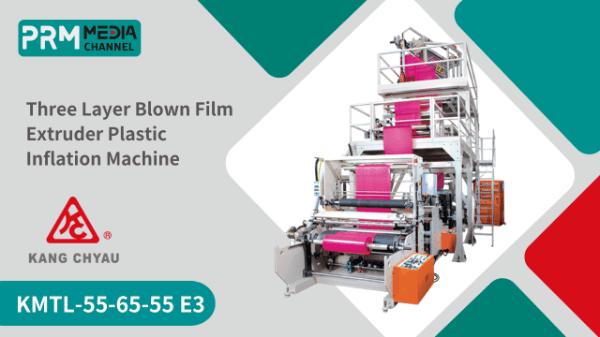

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

-

Two Platen Injection Molding Machine 600TPIIR | CLF

-

GMA 30th Anniversary - Extrusion Dies Empowered by Innovation | GMA

GMA 30th Anniversary - Extrusion Dies Empowered by Innovation | GMA

-

Product Enhancement Through In-mold labels & Heat Transfer Films | XIANG IN

Product Enhancement Through In-mold labels & Heat Transfer Films | XIANG IN

-

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Rubber & Silicon lnjection Molding Machines | LONG CHANG