Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

Co-rotating Twin Screw Extrusion | CYKF

Did you know that? Because of the low cost and material versatility, strand pelletizing is the most commonly used pelletizing system. Description: 1. Heating & Cooling System: The material can keep the best temperature in the manufacturing by alternatively using hot water and cold water. 2. Stable Feeding System: The designed screw can avoid material stuck and causing uneven feeding. The feeding quantity can be adusted according to needs. 3. Side Feeder: Used for adding additives including powder, liquid, or pellet type, the side feeder can arrange an automatic system that supplements additives by itself. 4. Vacuum Unit: Purify the pellet by getting rid of exhaust gas or steam from materials. 5. Water Cooling Unit: The water tank cooled the strand plastic, and the organized water tank remains the proper temperature to make the plastic straight and unbroken. 6. Dryer: The dryer removes water from the strand plastic surface with strong wind, and the removed water will return to the water tank eventually. 7. Pelletizer: The pelletizer cut strand plastic into pellets, and the rotate speed can adjust freely, customers can also change other models for bigger productivity. More product information please visit our website: https://www.cykf.com.tw/tw/product/Strand-Pelletizing-System.html

Garbage Bags on Roll Making Machine:SOSR-1000-2T-R+L

Fully Automatic High Speed Single Line Core-less Garbage Bags on Roll Making Machine with label device Model : SOSR-1000-2T-R+L • Core-less bags on roll • Bottom sealing bags with V, C, N, M shape • Shuttle sealing & feeding system • Label device

Taiwan Injection Molding Machine | CLF

Taiwan Injection Molding Machine - Chuan Lih Fa Products: plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

Quick Die Change System | FORWELL

Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management.

Flat Yarn Extrusion Line & Raffia Tape Stretching Line | HAO YU

HAO YU Raffia Tape Stretching Line is designed for producing PP/HDPE raffia tape and flat yarn. 【Equipment Features】 - Capacity: 160 ~ 520 kg/h - Designed for making 500-1500 denier - Working speed 100-270 meter/minute - A screen filter changer - Rotary blade slitting system - Synchronized control electronic system - Low energy consumption - Less downtime - Reduce production loss 【Additional Features】 - European-made gearbox - T-die - Melt pump - Tape winder - Designed for making 2000-6000 denier upon special request 【Finished Products】 - Woven bag - Geotextile - Artificial grass - Carpet backing production 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

2022 Intelligent Asia - Smart Mold, 3D Printing, Logistics & IoT | PRM Exhibition Tour

Let's PRM take you to the on-site through our online touring video!! In the video, you will be showed the advance technology of 3D printing, application of IoT in logistics and high quality of smart mold & die. 2022 Intelligent Asia has 9 major manufacturing sectors that includes Automation, Robots, Logistics, Cold Chain, 3D Printing, Molds & Dies, Laser, Fluid Power, and Smart Machinery.

Triangle Folding Machine & 1 Color Rotogravure Printing Machine | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000, MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES OF THE MACHINE: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

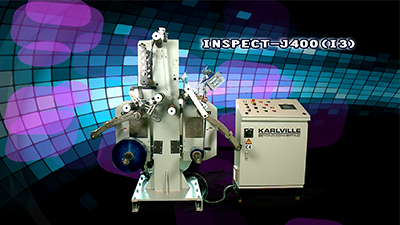

Inspection Machine | WEBCONTROL

Webcontrol Machinery Corp.- Manufacturer of inspection machine and more. More information about inspection machine: 1.Inspection Rewinding Machine- INSPECT-J300 2.Doctoring Rewinder Machine- INSPECT-H300/H400/H500 Webcontrol Machinery Corp has been specializing in manufacture of inspection machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our inspection machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast inspection machine service ensure our worldwide customers must be satisfied.

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.