Label Converting and Finishing System | YICHEEN

Machinery in the Video: Label Converting and Finishing System from YICHEEN Features: * Running operated by full rotary die cut method or intermittent die cut method. * Die is easy in change, save a lot of time in die mold adjustment. * Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession. * Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control. * Sensor detector and alert for broken material to reduce material lost. * Optional module for satisfying customized demands. * Optional Mechanism: EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet * Application: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material, and so on.

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

User Feedback from Azin Polymer | K 2022

It was an honor to interview Mr. Arash Alivirdi, a sales manager form Azin Polymer, at K 2022. He has been using PRM-TAIWAN for ten years. Let's listen his experience in using PRM-TAIWAN as a major platform for seeking machinery suppliers.

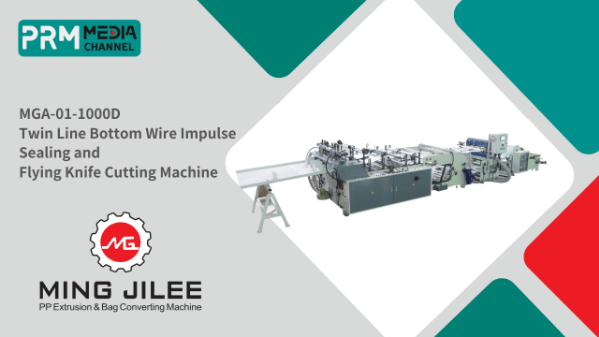

Twin Line Bottom Wire Impulse Sealing and Flying Knife Cutting Machine MGA-01-1000D | MING JILEE

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

Precision Mold Making & Injection Molding Solutions

Jia Thai Industrial Co., Ltd. Company Profile

IoT Injection Molding - Hot Runner Temperature Controller-TC50 | ARICO

【AUXILIARY EQUIPMENT IN THE VIDEO】 Hot Runner Temperature Controller-TC50 for Injection Molding Machines, IoT Solutions from ARICO. 【FEATURES】 HMI: 7" LCD display with touch panel Group setup function Mold Memory Power balance detection and display Synchronous heat up and cool down Self-diagnosis log Mold leakage detecting Injection machine connect for I/O function VNC function(option) 【SPECIFICATIONS】 Thermocouple type: J/K Temperature unit: ℃/℉ Heating mode selectable The maximum drive current is 15 ampere for each zone Temperature PID control Zero cross/Phase angle output trigger modes Auto detect the frequency of power source The current detect and display The output with auto/manual setting The soft-start for dehumidification Boost Standby Output mode: Stop/Manual/Slave/continually selectable when Thermo-coupler broken Overload protection for electric Overload protect for heating output The protect mode of power source when wrong input Auto shutdown when abnormal work on the module The fast fuse used to protect TRIAC 【ABOUT ARICO】 ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. Founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. ARICO is not only good at producing customized precision Hot Runner Temperature Controllers and related application equipment but also provides high-quality Hot Runner Temperature Controllers with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia, and other countries.

KAIMEI | PE Extruding Blow Molding Machine for Product Maximum to 1,500L - PBI-1305X-

Kai Mei Plastic Machinery Co., Ltd. established in 1977, is a highly reputed manufacturer of blow molding machines. Different types of machines are designed to produce containers of various raw materials such as PE, PVC, PP, PETG, PU, etc. Kai Mei can produce 5-ml containers of PBA Series Machines to 1,500-liter containers of PBI-X Series Machines. These are fully recognized by customers around the world.

2024 NPE Orlando Interview | WIPA

We are honored to have our first interview with Wipa, a high-quality plastic recycling machine manufacturer from Germany. In this interview, Wipa introduces their latest machine show at NPE, highlighting its features and benefits for the plastic recycling industry. Join us to learn more about this innovative technology and how Wipa continues to lead performance.

PLASTIMAGEN Light 2021 | PRM Media Channel Exhibition Insight

Recently on PRM Media Channel, we had our second online interview with PLASTIMAGEN Mexico, one of the greatest and biggest Plastic Industry Exhibitions of Latin America in Mexico. In the interview, the Vice-President of Tarsus in Latin America, Paul St. Amour, walked us through their audacity brand new project called“PLASTIMAGEN® LIGHT”. This special version of the exhibition was organized after they collected some surveys they sent to their overall exhibitors and resulted in a large minority needing to participate in this event. Differences between PLASTIMAGEN and PLASTIMAGEN Light: During the interview, it was mentioned that PLASTIMAGEN Light will be very much different from the normal version in terms of the vast of machinery that will not be able to be present due to the fewer exhibitors attendees and the location of the event will be relocated and will no longer be at the Convention Center, where it was normally held. Also, this new version will consist of a complete first line of hybrid technology where Digital Exhibition will be the main focus in advantage for all the international and local exhibitors and visitors who are unable to attend the 2021 exhibition.

3 Layer Air Bubble Film Extrusion Line | CHI CHANG MACHINERY

【Applications】 The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope. 【Compnay Introduction】 Since our founding in 1972 CHI CHANG MACHINERY ENTERPRISE CO., LTD has been on a never-ending quest for breakthroughs and innovations in technology. CCM ensures that wherever our customers are in the world, all of our extrusion equipment and services reach outstanding levels of performance. Adhering to our motto of Integrity, Innovative technology and Sustainable services, CCM is dedicated to the design and fabrication of plastic extrusion machinery.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

6 Cavities Automatic Injection Heading Machine | BONMART-

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.