Sensing & Polymer Test Equipment at K 2022 | Dynisco

We are glad to have an interview with Bill Desrosiers, Vice President of Dynisco, since our last interview at K 2019. The industry has been changed a lot due to COVID said by Mr. Desrosiers. Moreover, we had a discussion of how Dynisco implemented trending topics at K 2022, such as Circular Economy, Digitalization and Environment Protection, and applied these concepts in Dynisco products.

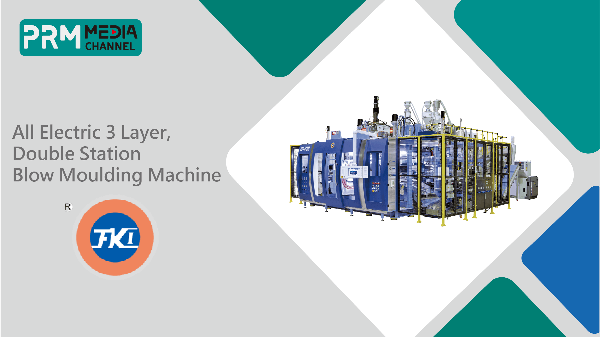

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

All Electric 3 Layer, Double Station Blow Moulding Machine for plastic bottle making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system. Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com

4000 ton injection molding machine | CLF

4000 ton injection molding machine - CLF CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

PRM-TAIWAN @ CHINAPLAS 2021 | Exhibition Opening

PRM Media Channel is happily reporting from CHINAPLAS 2021! In recent years many exhibitions have been canceled or postponed. Despite the COVID-19 pandemic, by implementing strict safety regulations, CHINAPLAS opens its door today once again to assist many exhibitors and the visitor to cultivate plastics and rubber industry. There will be many on-site and online activities expected to take place concurrently. Stay tuned to PRM Media Channel and PRM-TAIWAN B2B platform to gather more insight into CHINAPLAS 2021 activities. We will be posting more content and news about the event.

Vertical Injection Molding Machine Rotary Table | TAIWAN KINKI

MACHINERY IN THE VIDEO: Vertical Injection Molding Machine -Rotary Table KT 300R 3S FEATURES: -Vertical mold clamping and injection, small footprint, and high degree of precision. This machine is ideal for the injection of medium and small products with inclusions. -The Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. -Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. -Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. -This machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production.

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

Hydraulic Slitter and Cutting Machine | Yicheen

Hydraulic Slitter and Cutting Machine

2024 CHINAPLAS Interview | ETERLONG

We are here with Melody from Eterlong Co., Ltd at the CHINAPLAS. ETERLONG is known for high-quality products, such as blown film machines, extrusion die and extruder filters, and their post-sale service. We gained information about how ETERLONG applies digitalization to their equipment.

2024 CHINAPLAS Interview | ChumPower

We are here with Mr. Bush and Mr. Michael from HCI Converting Equipment at the CHINAPLAS. Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries.

Blown Film and Recycling Machines (Chinese Version)- POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, our PRM Director Alice will be carrying the interview with the CMO Mr. David Lo. During the interview, Mr. David Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

PRM Buyer Guide | PRM-TAIWAN

We have over 200 of the biggest and many of the small and medium-sized Taiwanese machinery manufacturers on our site and contacts with many more. Whether you are looking for full lines such as recycling machines extruders, blow molding machines, injection molding machines and printing machines, or auxiliary equipment and parts such as gearboxes, barrels, screws, molds, dies, control systems, and virtually anything related to the plastic and rubber industries including packaging. If it’s made in Taiwan, we will find it for you!