Quick Die Change | FORWELL

Quick Die Change - Quick Die Change System-qdcs-en-Forwell Features : • Decreased die change time • Designed for hydraulic and pneumatic presses • Increased efficiency • Reduced labor costs • Safer operations System Introduction : Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management. Quick Die Change Systems are becoming a standard for large manufacturers as they not only increase production efficiency, but also improve the overall working environment. The Automatic Die Change System can be built specifically for your machining requirements and will drastically reduce machine idle time during die changes, boosting your competitiveness. There are also a number of indirect benefits of installing a Quick Die Change System for your hydraulic and mechanical type press machines. Firstly, automated operations reduce labor expenses, but also reduce workshop accidents and the physical stresses on operators, making them more productive. Secondly, all dies can be changed without any modification allowing for the use of standardized die and press equipment, saving costs. Lastly, multiple presses can share a single Quick Die Change System, further economizing on costs and resulting in higher efficiency and productivity.

Solventless Laminating Machine (LM SF1300T) | WEBCONTROL

Webcontrol develops innovative solventless laminators with driven coating system and automatic turret unwind & rewind for high efficiency, consistent tension & minimum waste during roll changes.

Accumulator Head Blow Molding Machines | FONG KEE

Accumulator Head Blow Molding Machines | FONG KEE Specializes in Accumulator Head Blow Molding Machines, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Accumulator Head Blow Molding Machines manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Accumulator Head Blow Molding Machines and etc. If you are looking for good Plastic Blow Molding Machine Supplier, please feel free to contact us.

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

HSIN LONG Blown Film Die Heads | CHINAPLAS 2021

PRM Media Channel is very glad to announce the great cooperation with CPRJ, the official media group of CHINAPLAS. For this great opportunity, we bring you one of our special actors in the Blown Film Die Head Industry to share with us important facts & insights into the industry, and how their expertise reflects an outstanding performance on customer service, manufacturing process, and quality field. With half a century of rich experience in manufacturing, HSIN LONG is mainly specialized in producing Blown Film Dies and related components. These components can be applied in Packaging Films, Barrier Films for food packaging, Technical Films for high-tech applications, Sealing Films, Agricultural Films, Medical Films, Shrink and Stretch Films, TPU Films, Biodegradable Plastic Bags / Green Plastic Bags, and many more. In this video, our PRM Marketing Specialist Billy will be carrying the interview with the Special Assistant to the GM, Sandy from HSIN LONG Thread Rolling Co.

CHINAPLAS 2021 | PRM What to Say EP1

PRM Media Channel is here with a brand new program: PRM What to Say. More Info: https://bit.ly/2RngTZM Due to the rapid transformation in many industries because of pandemic, including plastics and rubber industry, we all realized the power of social media and video marketing. Through PRM What to Say program hosted by PRM Media Channel, we aimed to bring current issues of plastics and rubber industry on the table, and discuss these topics with experts and listen the possible solutions. Let's take a look at our first episode about CHINAPLAS 2021 and let us know your opinions and questions in the comments section. Thank you for your support!~

Solventless Lamination - Webcontrol

Solventless Lamination - Solventlless Laminator-LM-SF1300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Solventless Lamination since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Lamination with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Lamination service ensure our worldwide customers must be satisfied.

Aluminum Foil Printing Techniques | WORLDLY

Have you ever wondered how essential it is for manufacturers and consumers to have the right packaging or sealing material on a decomposable product like medicine, snacks/drinks, or any other related product? By interviewing Klive from WORLDY, we have been explaining what kind of technical strengths Worldly has and they are capable of manufacturing and designing customization machines according to client's demand. Moreover, You will obtain the knowledge of the difference between plastic and aluminum foil to understand the applications of each materials.

Bangladesh Culture and Tips on Operating Market | PRM What To Say EP18

Bangladesh has a rich, diverse culture. Its deeply rooted heritage is thoroughly reflected in its architecture, dance, literature, music, painting and clothing. For this episode, we’re going to talk about Bangladesh culture and tips on the operating market. Let PRM Cicilia share her insight and observation about Bangladesh Market!

Water Transfer Printing Dipping Machine | YHT

Since 1990, YHT has been a manufacturer for Printing High Definition Water Transfer Films, leading the way with short new pattern development time, quick lead time to turn around on film printing orders, and providing many solutions to qualify customers demands. We have been supplying films to many famous brand companies all around the world, and these work experiences have made us irreplaceable on Water Transfer Printing (WTP) business. We not only do printing films, but we also make relevant dipping and wash machines to supply a completed chain of product. 【Advantages of our Water Transfer Printing】 Color and design of the pattern through water pressure Decoration is possible for many sizes, shapes, and flexible products 【Applied Products】 Ski goggles, EVA shoes, electric switches, rifle scope, firearm, crossbows, dog leashes, home appliances, car panels, and steering wheels are all in the scope of WTP process.

PET Recycling Innovations and Sustainability through Plastic Recycling | PARTICO

This time our guest is Partico Machinery Inc. Partico stands out with its customized thermoplastic recycling machines in Taiwan with over 25 years of experience. Dear Denny Chang and Lucy Huang, the sales representatives of the company, were really intimate to share their company's innovations and investments in R&D. By developing PET vacuum extrusion pelletizing system, Partico makes a distinction from other traditional manufacturers and creates its own market value. As a manufacturer of extrusion pelletizing machines, Partico is dedicated to calling for the importance of sustainability. The purpose of the company is not only to manufacture plastic recycling machines for the industry but also to assist in environmental protection with efficient machinery, as a part of the company's ESG contribution. The most important thing is that Partico is familiar with various materials that its machines can recycle. In addition, Partico is also capable to plan suitable conveyor systems for the customers according to their materials characteristics and applications, so they do not need to worry about the overall planning of equipment. In recent years, the main trend in the PET recycling industry is to apply pellets to make food contact materials. One of Partico's goals is to get FDA certificate, which refers to manufacturing recycling machines that recycle PET flakes for food packaging applications. We have more to share, then let's take a look at this intimate interview and learn more about Partico and its innovative contribution to the plastics recycling industry.

TAIPEIPACK 2023 On-site Tour| PRM-TAIWAN

TAIPEIPACK 2023 exhibition tour is coming! Follow Daniel to learn about Taiwanese packaging manufacturers And the first-hand industry information!

Shredder Integrated Recycling Machine | GEOR-DING-

Shredder Integrated recycling machine Features: -Can handle large heavy materials or thin-film materials 0:50 -Automatic backfllush screen changer,Reduce the screen changing labor cost 1:03 -Side Feeding Twin Screw design

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

Innovative Technology in Plastic Recycling | BoReTech-

BoReTech is a leading company in the plastic recycling industry. With more than 30 years experience in the industry, BoRetech is introducing its brand new designed ES process.

New Brand Release | PRM-TAIWAN

Throwback to PRM-TAIWAN's New Year Resolution of 2019, the new brand image! PRM-TAIWAN(Plastic and Rubber Media Taiwan) is here to start 2019 with a BAM! Standing firmly as the number 1 platform for Taiwanese plastics and rubber manufacturers, our dreams does not stop here. Although already influential, our goal is to further penetrate global markets including but not limited to the Spanish, European, African and Russian markets. To show our resolve, PRM-TAIWANwill like to present to you our brand new look! The logo is a manifestation of PRM-TAIWAN. With the color representing our mindset, shape representing our physicality and missing pieces as our motivation. Now let us embrace 2019 and shine to the world! Read more: https://www.prm-taiwan.com/industry_i_2019011800001.html

Shanghai World of Packaging (swop) 2024

Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd. will join hands to present the Shanghai World of Packaging (swop) from 18th to 20th November 2024 at Shanghai New International Expo Centre (SNIEC). As a member of the interpack alliance, in addition to continuing to exhibit the packaging industry chain, swop will discuss industry-leading keywords with packers, brands, OEM/ODM, including lightweight, light assets, youth, intelligence, personalization, new materials, new technologies, sustainability, new design trends and other popular topics, sharing packaging cutting-edge concepts and technologies. From materials, equipment, and products to design and marketing, swop is definitely your 360° solution provider in the packaging industry! Find out more at https://adlnk.cn/A3Qm7K5

PET Bottle Recycling System and Process for Food Grade Flakes | BoReTech

BoReTech has been a specialized manufacturer focusing on the customized R&D for PET recycling production since 1989. Moreover, the company also has more than 15 years of manufacturing experience. BoReTech provides a total solution of the plastics recycling system, polyester staple fiber production, and many more. In the video, you will find the on-site machine introduction of : PET Bottle Recycling System Process for Food Grade Flakes Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry As PRM Media Channel, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! The Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the company’s profile and the current situation of COVID-19 in Mexico, the challenges they are having due to the pandemic, and their solutions to overcome those challenges.

VDMA Interview | Insight into the European Plastics & Rubber Market

We are excited to share the interview with Mr. Florian Mikulasch from Germany, who is the Marketing Analyst of VDMA (German Mechanical Engineering Industry Association). Mr. Mikulasch shared a clear insight into the German and European Plastics & Rubber Market, the current problems due to the pandemic, the second lockdown in Germany, and the solutions that companies and associations bring to life to ease the effects of the pandemic. Welcome to add comments and ask your questions in the comment section. Also, let us know about the video interviews (Such as which market?) that you would like to see on PRM Media Channel.

Industry 4.0 Smart Factory for Injection Molding - sFactory 4.0 | SHINI

【VIDEO FOCUS】: SHINI Industry 4.0 Smart Factory for Injection Molding which is called "sFactory 4.0" 【ABOUT SHINI】 Derived from Taipei, Taiwan, Shini group has gone through an extraordinary journey for more than 40 years. To date, Shini group has established six production bases and one corporate technology center globally. Specialized in manufacturing plastic auxiliary equipment, Shini products consist of eight series, including drying & dehumidifying, feeding & conveying, dosing & mixing, heating & cooling, granulating & recycling, automation solution, systematic solution, and hot runner system. Adhered to the management principle “focusing on a particular business, pursuing to be the world leader”, Shini people have created new situations one after another. Till now, Shini group has ranked among the world-class manufacturers of plastic auxiliary equipment and taken the lead of Asia's plastic auxiliary equipment industry.

2024 TaipeiPlas International Plastics & Rubber Industry Show| Geording

In this video from the 2024 TaipeiPlas International Plastics & Rubber Industry Show, we present Geording’s machine designed to support green policies. With a self-cleaning screen changer, their equipment helps customers enhance efficiency and focus on green recycling development. Geording has maintained a long-term working relationship with Polaris, and we explore their experience with our services. Watch to learn more about Geording's commitment to sustainability in the plastics and rubber industry!

Bag Making Automation Solutions at K 2022 | PLAS ALLIANCE

It's such a great honor to interview Eugene Chiu, the Sales Manager from PLAS ALLIANCE LTD. In the interview, he mentioned influences by the pandemic. In the end, he also talked about the trending topics in recent years, for instance, Circular Economy. PLAS ALLIANCE LTD. also has excellent customization ability. They provide customized machinery, especially when their customers are searching for Biodegradable Materials applications.

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

The Cliff's Notes of Chinese Market | PRM What to Say EP2

We are very excited to announce that our general manager, Hero, went to China for CHINAPLAS 2021. It was our pleasure to invite him to PRM Media Channel to share Cliff's Notes on the Chinese Market. Hero mentioned the quarantine process, CHINAPLAS 2021 on-site observation, the escalating demand in China, and the recent Alibaba case in the Video. Moreover, Hero is surprised how the Chinese market digitized, which we should work on. Therefore we are working on creating a borderless environment for our viewers. VIDEO OUTLINE 0:00 Video Starts & Introduce our general manager, Hero 0:50 Experience of Quarantine Process 1:20 Insight into CHINAPLAS 2021 2:23 Domestic Demand in China 4:06 Changes in Chinese Lifestyle 5:44 Brief Talk about Alibaba Case Know us more on PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Positioning swop as a Packaging Industry Leader: Insights from Adsale’s VP, Rita| Shanghai swop 2024

In my latest interview at swop, I had the honor of speaking with Rita, Vice President of Adsale, one of the key organizers of this impactful exhibition. Rita shared her perspective on how Adsale strategically positions swop as a cornerstone for the packaging industry, fostering meaningful connections and driving innovation. She also revealed Adsale’s core mission behind organizing exhibitions like swop and how they contribute to shaping the future of the industry. Curious about how swop creates value for packaging professionals worldwide and what to expect from this pivotal event? Don’t miss Rita’s insights and her vision for swop’s role in the global packaging ecosystem.

T-Shirt Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines T-shirt bag on roll making machine High production efficiency to save men power and time Computer control over the entire process From film roll to final bag, once process flow Servo motor, as standard attachment, makes it easy to adjust the bag length and production speed Automatic film feeding, coordination free from tension adjustment Oscillation film feeding system for stability and high out put Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses Automatically core changing system Punch system on magnetic roller 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES OF THE MACHINE: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

2024 CHINAPLAS Interview | ETERLONG

We are here with Melody from Eterlong Co., Ltd at the CHINAPLAS. ETERLONG is known for high-quality products, such as blown film machines, extrusion die and extruder filters, and their post-sale service. We gained information about how ETERLONG applies digitalization to their equipment.

K Show 2022 Press Lunch Event | PRM x Kaigo

Are you excited to participate K Show 2022? You cannot miss the chance to watch this teaser! PRM will release the full videos or the following sharing session in September. Stay tuned! PRM was invited to join K Show 2022 Press Lunch organized by Kaigo Co., Ltd. Exhibitors who are participating in K Show 2022 were gathering in the event to be presented the show trending in this year, such as Circular Economy, Digitalization and Climate Protection. Sharing sessions was hold in the event which given by 1. Welcome Opening of Press Lunch - Kaigo Co., Ltd. Project Manager Mr. Richard Keim 2. K Show 2022 Trending - Kaigo Co., Ltd. Project Manager Mr. Alexander Keim 3. Make Plastic Green - Plastic Industry Development Center VP Ph.D Chiu Zen-Wen 4. Exhibition in Post-pandemic Era - Airtrade Express Ltd. Mr.Tommy Shih

Garbage Bags on Roll Making Machine:SOSR-1000-2T-R+L

Fully Automatic High Speed Single Line Core-less Garbage Bags on Roll Making Machine with label device Model : SOSR-1000-2T-R+L • Core-less bags on roll • Bottom sealing bags with V, C, N, M shape • Shuttle sealing & feeding system • Label device

Thermoforming Systems at K 2022 | ILLIG

It was a great honor for PRM to interview the Sales Director — Adam Liang from ILLIG. ILLIG showcased their newest Thermoforming Machine at K 2022. Integrated Sustainability and Digitalization into product applications, including recyclable and biodegradable PP flakes. Mr. Liang also shared his insights for the future in the Plastic & Rubber industry.

Upstream and Midstream of Taiwan Automation Manufacturing | What To Say EP16

Have you ever wondered why Taiwan is an automation and automotive parts manufacturing stronghold? In this episode, you will be explaining the first two streams, which are upstream and midstream, which are the initial points for the following procedure of the automotive industry.

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

JIT-SS |JIT T-Shirt Bag Making Line |JANDI'S

【Machine Features】 Mono-layer, 2+0 printing Power Required Reduced Processing Waste Reduced Production Mistake Reduced CO2 Emission Reduced Total Lead Time Reduced Labor Cost Reduced Recover Die-cut Material Storage Space Reduced 【Company Intro】 JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

2024 NPE Orlando Interview | WIPA

We are honored to have our first interview with Wipa, a high-quality plastic recycling machine manufacturer from Germany. In this interview, Wipa introduces their latest machine show at NPE, highlighting its features and benefits for the plastic recycling industry. Join us to learn more about this innovative technology and how Wipa continues to lead performance.

Customization & After-sale Service | GENIUS

More and more countries request all plastic-made products to be fully recycled; therefore, plastic recycling machines have been important. Mr. Peter Tsai, the general manager of Genius, explained the best seller “Single Stage Cutter Compactor Plastic Recycling Machine” as known as KRIEGER series in their product lines. This machine is capable of recycling HDPE drums and films with superior features, such as Italian-made heater, extruder-degassing vents, dual piston filters. With excellent customer satisfaction and customization service, Genius awarded an order from a returning Japanese client again. According to the language and the use habits, the parts of the machine have been installed with many Japanese brands in order to lessen obstacles while Japanese employees operate the machine. Moreover, Peter has expressed how Genius values customer satisfaction, customization service and after-sales service in the interview. Through this video, you will be showcased how Genius is running the testing of Single Cutter Compactor Machine before shipment. 【Brief Intro】 Genius Machinery specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipment. 【Video Outline】 00:00 - Introduction 00:31 - Machine Testing & Superior Features 02:10 - Conveyor Belt 02:19 - Compactor 02:50 - Extruder-degassing 03:19 - Dual Piston Filter 03:40 - Pelletizer 04:18 - Details of customized control panel 05:21 - Materials Process & Applications of Machine 06:27 - After-sale service for installation & maintenance 08:05 - Messages to customers

Triangle Folding Machine, 1 Color Rotogravure Printing | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000 from MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

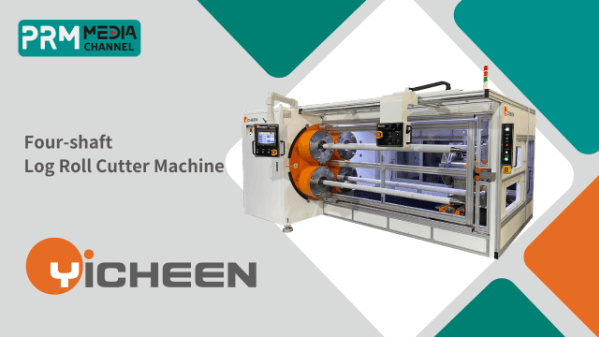

Automatic Log Roll Cutting Machine|Four-Shaft Log Roll Cutter | Yicheen

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw / Automatic Log Roll Cutting Machine Features / Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down. PLC control system Auto change cut size setting in the same shaft. Precise and smooth positioning. Multi-speed cutting rolls to improve operating efficiency and maintain high quality. The blade has different angle changes according to different materials, reducing the number of tool changes. / Advantages of Yicheen / Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions. / links of Yicheen / Contact us: https://bit.ly/3q8KLaK Subscribe us: https://bit.ly/3wGjjU3 Product Info: https://bit.ly/3tU2QdK

2023 Plast Eurasia Interview | WEI MENG

It's our great honor to interview WEI MENG and their Turkish agent in the 2023 PlastEurasia. Watch our video for more information!

Quick mold change system|QMCS|for Injection molding|Sistemas de cambio rápido del molde|FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations. When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits. Indirect Benefits Die Standardization Press Standardization Increased Safety Improved Working Environment Increased Competitiveness Direct Benefits Reduction in Die Change Time Efficient Small Batch Runs Reduced Stock Handling Higher Productivity and Quality Reduction in Labor Costs

PP Woven Bag Fully Automatic Liner Inserting-Bag Top Hemming Conversion Line | BOTHEVEN

【MAIN FEATURE】 All in one multi-functional machine - Flexible Usage for various type of PP woven bag Processing on the same machine. Available for PP woven bags: ● With liner Inserting-Cutting-Sewing and bag top hemming process ● With Cutting-Sewing and Bag Top Hemming Process Only (Without Liner Inserting) ● With Liner Inserting-Cutting-Sewing Only (Without Bag Top Hemming process) Cutting-Sewing Process only (Without Liner Inserting & Without Bag Top Hemming) Saving Manpower, Space and Saving Cultivated Training for Skilled Manual Operation to the Maximum. Producing Finished Bags with Conformed & unified quality with stable performance Experiencing Clean Process of Bag Top Hemming, largely Reducing Hang-Touching on the bag top area. Highly synchronized machine for Easy Setup and quick bag size changeover. A Total-Solution Machine for PP woven bags with Final Products Applicable in a Big Variety Market. 【COMPANY INTRO】 Botheven Machinery Industrial Co., Ltd, (Since 1984), has accumulated more than 30 years of technical experience & know-how in the planning design, manufacturing, sales and service of PP/HDPE Woven Bag Making Machines in Taiwan. Our equipment has been sold worldwide with assured quality, stable performance and reliable after-sales services. We can build machinery according to customers' requirement; also provide cost-down solution for customers.

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

Taiwan Injection Molding Machine | CLF

Taiwan Injection Molding Machine - Chuan Lih Fa Products: plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html

High Speed Co-Extrusion Coating and Laminating Machine WCL-H-1300| WORLDLY

High Speed Co-Extrusion Coating and Laminating Machine WCL-H-1300 (300 m/min) WORLDLY In this fast-changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds of resin or more by two or more extrusion units to create multi-function extrusion layers. The variety of resin after melted and go through the feed block then join into the T-die. The side screw has corrosion resistance treatment. It’s fine to work with acid copolymer resin, such as EVA, EAA, EMAA, and Surlyn, etc. The barrel heated by a ceramic heater to ensure more energy-saving and short start up time. Worldly also developed the exclusive extrusion output control system with Germany leading dosing system company. So it provides the very accurate and stable output and coating gauge control during the production. It can save more material especially for the long run jobs. The high-speed H series version of the rewinding splicer adopted with a tracking roller device. It provides two kinds of gap & contact winding mode and gives a uniform and perfectly straight finished winding during high speed running. Also the taper tension can properly control the winding from the beginning roll. So it can reduce the wastage and avoid the wrinkle generate at the inner roll. Worldly utilizes only high quality imported T-dies and maintains a ±3% thickness variation. The inner deckle system is customized in-house to reduce trim and provides uniform high-speed production.