CHINAPLAS 2021 PRM Trade Show Activities | PRM Media Channel

Throwback to CHINAPLAS 2021 to share the online and offline events of PRM. More Info About PRM Online Exhibition: https://bit.ly/3f1UN8t Let's take a look at PRM Trade Show Activities related to this biggest plastics and rubber industry exhibition in Asia. It was our pleasure to attend CHINAPLAS 2021 this year. Since the pandemic, the foreign visitors and exhibitors have been fewer than in previous years; however, PRM understands our customers' and international buyers' circumstances. In this video, you will find our exhibition activities, including matchmaking buyers and manufacturers of the plastics and rubber industry through our in-time inquiry system. During the exhibition, PRM observed the Chinese market and CHINAPLAS, also we have interviewed exhibitors to gather more profound insight into the market. You can find detailed information on our Youtube Channel, E-newsletter, and social media platforms that are provided below. We also cooperated with Adsale, the organizer of CHINAPLAS, to bring out interview videos and the Livestreams about the current situation of the plastics and rubber industry and their solutions. For more information and videos, please visit our PRM-TAIWAN TechHub@CPRJ at https://bit.ly/3f1UN8t Follow PRM Media Channel on: YouTube: https://www.youtube.com/c/PRMTaiwan Facebook: https://www.facebook.com/PRMTAIWAN Linkedin: https://www.linkedin.com/company/prm-taiwan/

Air Bubble Film Extrusion Line - CHI CHANG

Air Bubble Film Extrusion Line - 2.5M Wide 3-layer Air Bubble Sheet Extrusion Line The 2.5M Wide, 3-layer Air Bubble Sheet Extrusion Line produced by Chi Chang Machinery Enterprise Co.,LTD has excellent quality and an outstanding reputation. The Air Bubble Film Extrusion Line includes Take-off unit & winder, In-line lamination, T-Die & laminating unit and EPS/EPE reclaim system.

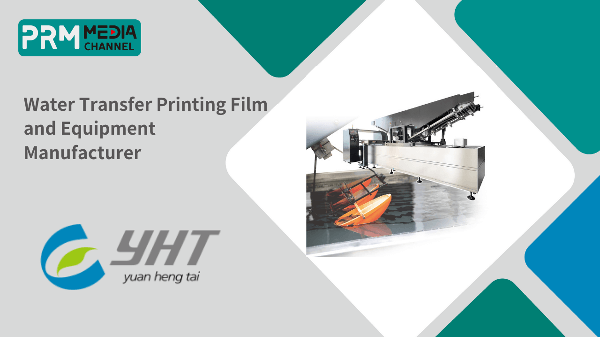

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

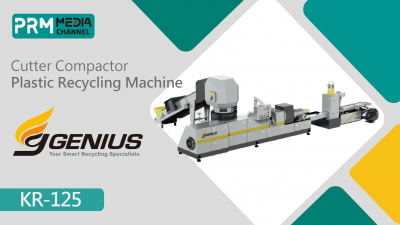

Cutter Compactor Plastic Recycling Machine - KRIEGER Series | GENIUS

Machinery in the Video: GENIUS KRIEGER Series - KR-125 Cutter Compactor Recycling Machine [VIDEO HIGHLIGHTS] 0:00 Plastic Recycling Machine - KR-125 0:28 Belt Conveyor 0:41 Cutter Compactor 1:00 Main Extruder 1:11 User-Friendly Control Panel 1:26 Dual-Piston Filter 1:36 Die-Face Cutting Pelletizing [KEY FEATURES ] Applicable Materials: PET, PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS, etc. Especially for plastic films, foam, woven and non-woven fabric, raffia, washed & squeezed films, flakes, edge-trimmed, and cutting-edge materials. High torque precision gearbox. Low noise and steady operation. Die-face pelletizing is expected to reduce manpower costs. The screw is specially designed for recycled materials based on their characteristics. The unique design ensures full degassing in operation. SAVE cost, energy, and time. The single extruder is suitable for clean materials such as injection leftovers and production waste. [COST SAVING] Saves energy cost up to 20% Reduces labor cost as only 1~2 operators are needed to operate the whole plant. [SUPERIOR FEATURES] /Compacting & feeding/ The high-speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processing. Increase the highest throughputs for more productivity. /Multiple Cooling/ Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The operator can set the temperature of each to stably control the compactor’s temperature. /Flexible Customization/ GENIUS recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients’ needs, presenting a smart and reliable plant.

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT Originated from the parent company Alfa Auto Machinery Co., Ltd, Gamma is established based on the specific needs of customers. The chairman of ALFA, Mr. Shi Fuxing founded Dongguan Gmtek Technology Limited and Suzhou Gamma Automation Tech Co., Ltd in 2006 with the foundation of 2 million US dollars. The main services of Gamma are precision machining and professionally developed and manufactured high speed vertical machining center. Since the establishment, Gamma strives to fulfill the requirements of the customer and continue to provide the customers with the best service no matter if it’s precision, machining speed , the cost performance or the flatness.

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~

2024 CHINAPLAS Interview | Shubham Extrusion

We were delighted to have CHINAPLAS at the ETERLONG booth and meet their largest buyer in India for an interview with us. Mr. Nirav Shah shared that 15 years ago, TAIPEIPas found their trusted partner through PRM-TAIWAN

Blown Film Extrusion Line | FONG KEE

Blown Film Line - Three Layer Co-Extrusion Blown Film Line Located in Taiwan, FKI is the manufacturer of Three Layer T-Die Co-Extrusion Cast Film Machine. The demand of the Mono Layer/Multi layer T-Die Cast Film Extrusion Line has became more and more, which widely involved in many applications of packaging field, such as: 1. Decoration film 2. Gift wrapping film 3. Flower wrapping film 4. Stationery product packaging film 5. Lining film for dry/wet lamination 6. Sanitary product packaging film 7. Flexible packaging film 8. High barrier food packaging film With its outstanding optical and physical properties, either the mono layer or multilayer cast film being widely used in many applications, due to the well developed materials grades and additives, plus the well designed processing equipment with high precision control system as a full package to set the positiveness.

2024 CHINAPLAS Interview | ETERLONG

We are here with Melody from Eterlong Co., Ltd at the CHINAPLAS. ETERLONG is known for high-quality products, such as blown film machines, extrusion die and extruder filters, and their post-sale service. We gained information about how ETERLONG applies digitalization to their equipment.

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

All Electric 3 Layer, Double Station Blow Moulding Machine for plastic bottle making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system. Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com

3/5/7-LAYER CO-EXTRUSION BLOWN FILM MACHINE | CHYI YANG

CHYI YANG INDUSTRIAL CO., LTD. were set up in 1965, are inseparably linked with the life and development of plastic machinery in Taiwan. The 2nd eldest producer of plastic machinery and holds the reputation of being a reliable business partner. Our immortal goal is to improve & upgrade ourselves continuously and endless and to achieve the level of technology and production management which will ensure high quality of all products and services. We do hope to attract and care for customers by following the fundamental principles such as correct and refined manners in business relations, as well as skilled, flexible and reasonable management, to create a new era in PLASTICS.

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

Second Life to Recycled Plastics | BoReTech

Have you wondered how PET bottles have been recycled? Where do recycled plastics go? BoReTech is a leading company in the plastic recycling industry, who strives to solve plastic waste and give it a second life. With more than 30 years experience in the industry, BoReTech is able to process different materials from different countries and gain know-how experiences. Lately, BoReTech has redesigned their washing line in a smaller footprint, which is 50% less surface area compared to their standard line. Here are four improvements of the latest washing line called ES-process PET Bottle Recycling System. Smaller Foot Print Convenient in Maintenance Environmental Protection and Sustainability Quality Improvements To be a global pioneer in the plastic recycling ingenuity, BoReTech has gradually moved towards the research, development, and design of the all-plastic recycling process. Let's keep our environment in ecological balance and promote global sustainable development. 【Video Outline】 0:00 Reduction of Carbon Emissions 0:52 BoReTech's Plastic Recycling Solution 1:32 Journey to Plastic Recycling 3:11 Development of BoReTech 3:54 Innovation & Integration to meet food-grade demand 4:38 BoReTech PET Bottle Recycling System 5:10 ES-process PET Bottle Recycling System 7:07 Market share of BoReTech in India & Japan 8:51 Service from BoReTech 9:46 Future Development & Mission

Exploring the Future of Packaging Machinery with Thomas Dohse | Shanghai swop Interview

In this exclusive interview at Shanghai swop, we sit down with Thomas Dohse, a key figure from interpack, to dive deep into the future of packaging machinery and the emerging trends shaping the industry. Discover the fascinating highlights of the swop exhibition, including innovative technologies and unique insights into the latest advancements. Thomas also shares his perspective on the resurgence of globalization, which has taken a new form through fragmented and decentralized transactions, creating fresh opportunities for businesses worldwide. Finally, Thomas gives us a sneak peek into the 2026 interpack, unveiling its central themes and what we can look forward to in this global event. Don’t miss this insightful discussion that combines cutting-edge trends with a vision for the future of packaging!

New Brand Release | PRM-TAIWAN

Throwback to PRM-TAIWAN's New Year Resolution of 2019, the new brand image! PRM-TAIWAN(Plastic and Rubber Media Taiwan) is here to start 2019 with a BAM! Standing firmly as the number 1 platform for Taiwanese plastics and rubber manufacturers, our dreams does not stop here. Although already influential, our goal is to further penetrate global markets including but not limited to the Spanish, European, African and Russian markets. To show our resolve, PRM-TAIWANwill like to present to you our brand new look! The logo is a manifestation of PRM-TAIWAN. With the color representing our mindset, shape representing our physicality and missing pieces as our motivation. Now let us embrace 2019 and shine to the world! Read more: https://www.prm-taiwan.com/industry_i_2019011800001.html

Bottle Grade PET Bottle Washing Line | BoReTech

MACHINERY LINE IN THE VIDEO: Bottle-to-Bottle Grade PET Bottle Washing Line from BoReTech. The line is mainly used for PET bottle-to-bottle projects (FDA Approval), which recycles post-consumer PET bottles into rPET flakes. The regenerative PET flakes conform to the quality index requirements of downstream food packaging and are used for bottle blowing and packaging which can directly contact food after pelletizing and SSP processes in the late stage. HIGHLIGHTS Solutions for diversification of input PET bottle bales. Automatic de-baling technology, reduces labor, a strong bale breaking ability for high-density PET bottle bales. Patent technology for PVC label removal. Patented Pre-washing and hot washing process to ensure the cleanliness of rPET flakes. Integrated technology and capability for automatic sorting machine and PET bottle recycling line. The hot washing process reduces impurities content to achieve food-grade index. Stable and reliable quality of rPET flakes, online inspection to ensure the stability of rPET flakes. Completed online water recycling treatment system for pre-washing, hot-washing, and rinsing. Low operation breakdown, production management guidance service for the customers. FOOD GRADE PET BOTTLE RECYCLING PROCESS De-baling➜Metal Removal➜Label Removal➜Metal Removal➜Bottle Pre-washing➜Optical Bottle Sorting➜Manual Sorting➜Crushing➜Dust Removal➜FlotationHot washing➜Friction Washing➜Rinsing➜Flushing Washing➜Drying➜Dust Removal➜Optical Flakes Sorting➜Blending➜Online Inspection➜Packing FOLLOW PRM ON: PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ #BoReTech #PRMMediaChannel #PETrecycling #PETwashingLine #BottleToBottleRecycling #PRMTAIWAN #Plastics #Rubber #Industry #Internationalmarket #Export #machinery #PET #PETbottle #Recycling

2024 NPE Orlando Interview | WIPA

We are honored to have our first interview with Wipa, a high-quality plastic recycling machine manufacturer from Germany. In this interview, Wipa introduces their latest machine show at NPE, highlighting its features and benefits for the plastic recycling industry. Join us to learn more about this innovative technology and how Wipa continues to lead performance.

How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry. What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected? Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide. Topics Covered: U.S. reciprocal tariffs overview Strategic moves for manufacturers in 2025 Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Long Chang is manufacturing the series of Rubber & Silicon injection Molding Machines, and Heated Compression Molding Machines etc. 【Machine Series】 Silicone Injection Molding Machine Rubber Injection Molding Machine Horizontal Automatic Rubber & Silicone Injection Molding Machine Single Body / Twin Body Vacuum Oil Hydraulic Compression Molding Machine Vacuum Rubber Oil Seal Hydraulic Compression Molding Machine Single Body / Twin Body Die-Moving & Ejection Compression Molding Machine Four Columns Type Oil Hydraulic Press EVA Foam Tire / Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine 【Company Introduction】 Long Chang Mechanical lndustrial Co., Ltd. was established in 1971, under the leadership of president Huang Chin-Huo with the idea of "always be loyal to the obligation, give more than enough thought to operate the business" and demands "making the perfection more perfect" to be the target.

Flat Yarn Extrusion Line & Raffia Tape Stretching Line | HAO YU

HAO YU Raffia Tape Stretching Line is designed for producing PP/HDPE raffia tape and flat yarn. 【Equipment Features】 - Capacity: 160 ~ 520 kg/h - Designed for making 500-1500 denier - Working speed 100-270 meter/minute - A screen filter changer - Rotary blade slitting system - Synchronized control electronic system - Low energy consumption - Less downtime - Reduce production loss 【Additional Features】 - European-made gearbox - T-die - Melt pump - Tape winder - Designed for making 2000-6000 denier upon special request 【Finished Products】 - Woven bag - Geotextile - Artificial grass - Carpet backing production 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

HSIN LONG Blown Film Die Heads | CHINAPLAS 2021

PRM Media Channel is very glad to announce the great cooperation with CPRJ, the official media group of CHINAPLAS. For this great opportunity, we bring you one of our special actors in the Blown Film Die Head Industry to share with us important facts & insights into the industry, and how their expertise reflects an outstanding performance on customer service, manufacturing process, and quality field. With half a century of rich experience in manufacturing, HSIN LONG is mainly specialized in producing Blown Film Dies and related components. These components can be applied in Packaging Films, Barrier Films for food packaging, Technical Films for high-tech applications, Sealing Films, Agricultural Films, Medical Films, Shrink and Stretch Films, TPU Films, Biodegradable Plastic Bags / Green Plastic Bags, and many more. In this video, our PRM Marketing Specialist Billy will be carrying the interview with the Special Assistant to the GM, Sandy from HSIN LONG Thread Rolling Co.

Plastic Wood Composite Profile Extruding Machine | CHEN YU

Plastic Wood Composite Profile Extruding Machine | CHEN YU CHEN YU PLASTIC MACHINE CO., LTD is a professional designer and manufacturer in Plastic Wood Composite Profile Extruding Machine.

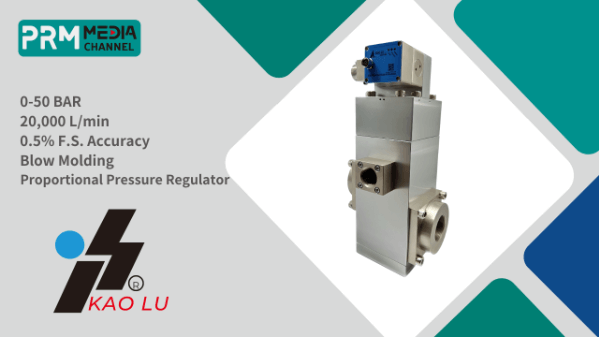

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd