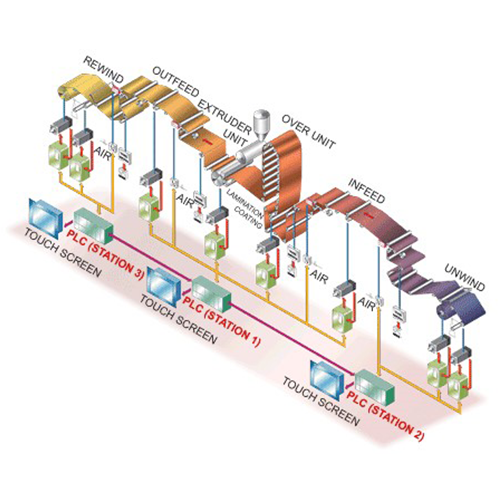

PLC STATION 1

- Laminating speed control

- Extruding speed setting

- Laminating parameter setting

- Operation temperature setting

- Driver status monitoring

- Production additives saving

- Malfunction warning information

- Tension information monitoring

PLC STATION 2

- Automatic unwind tension control

- Diameter detecting control

- Dancer roller tension control

- Automatic cutting roll change

- Jointing gluing surface check

- Automatic pre-drive jointing

- Automatic infeed tension control

- E/P transducer control

PLC STATION 3

- Automatic rewind tension control

- Rewind tape tension control

- Dancer roller tension control

- Automatic cutting roll change

- Non-stop roll change

- Automatic length counting

- Automatic outfeed tension control

- E/P transducer control

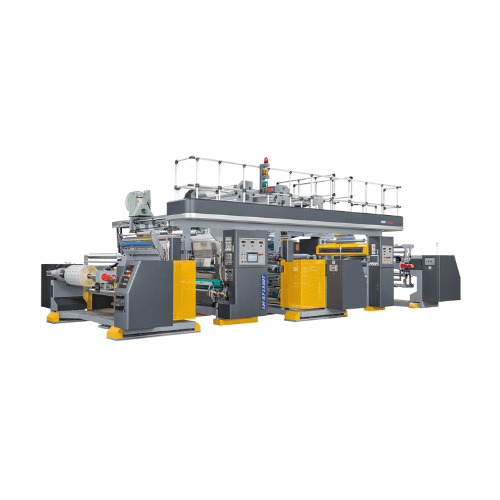

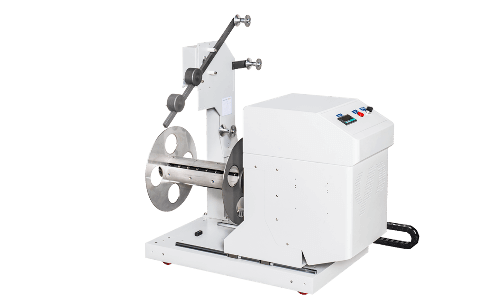

Extrusion System Lamination Machine

|

SUPER |

STANDARD |

POPULAR |

ECONOMY |

|

Main |

|||

|

AC vector motor & driver |

AC vector motor & driver |

AC motor & frequency inverter (11Kw) |

AC motor & frequency inverter (7.5Kw) |

|

First Unwind |

|||

|

AC servo motor & driver |

AC vector motor & driver |

Powder brake 10kg-m |

Powder brake 5 kg-m |

|

Low friction air cylinder 63 x 78 |

Low friction air cylinder 63 x 78 |

Auto tension control |

Manual tension control |

|

E/P transducer |

Precision air regulator |

|

|

|

Load cell & dancer roller |

Dancer roller |

Load celler |

|

|

Infeed |

|||

|

AC servo motor & driver |

AC vector motor & driver |

AC motor & inverter |

|

|

Very low friction Air cylinder 63 x 78 |

Very low friction Air cylinder 63 x 78 |

Low friction Air cylinder 63 x 78 |

|

|

E/P transducer |

Precision air regulator |

Precision air regulator |

|

|

Load cell & dancer roller |

Dancer roller |

Dancer roller |

|

|

Outfeed |

|||

|

AC servo motor & driver |

AC vector motor & driver |

AC motor & Inverter (2.2Kw) |

AC motor & inverter (1.5Kw) |

|

Very low friction air cylinder 63 x 78 |

Very low friction air cylinder 63 x 78 |

Low friction air cylinder 63 x 78 |

Low friction air cylinder 63 x 78 |

|

E/P transducer |

Precision air regulator |

Precision air regulator |

Precision air regulator |

|

Load cell & dancer roller |

Dancer roller |

Dancer roller |

Dancer roller |

|

Rewind |

|||

|

AC servo motor & driver |

AC vector motor & driver |

AC motor & driver |

DC torque motor & driver |

|

Very low friction air cylinder 63 x 78 |

Low friction air cylinder 63 x 78 |

Auto tension controller |

Manual tension control |

|

E/P Transducer |

Precision E/P Transducer |

|

|

|

Load cell & dancer roller |

Dancer roller |

Load cell |

|

|

Coating |

|||

|

AC servo motor & driver |

AC vector motor & driver |

AC motor & frequency Inverter (2.2Kw) |

AC motor & inverter (1.5Kw) |

|

Low friction air cylinder 63 x 78 |

Very low friction air cylinder 63 x 78 |

Low friction air cylinder 63 x 78 |

Low friction air cylinder 63 x 78 |

|

Precision control transducer |

Precision air regulator |

Precision air regulator |

Precision air regulator |

|

Second Unwind |

|||

|

Powder brake 10 kg-m |

Powder brake 5 kg-m |

Powder brake 5 kg-m |

Powder brake 5 kg-m |

|

Calculated auto tension control |

Calculated auto tension control |

Calculated auto tension control |

Manual tension control |

|

Load cell & dancer roller |

Dancer roller |

|

|

|

Extruder |

|||

|

AC servo motor & driver |

AC servo motor & driver |

AC motor & frequency Inverter (55Kw) |

AC motor & frequency Inverter (55Kw) |

|

PLC |

|||

|

Network type PLC |

San Shiah high speed PLC |

San Shiah medium PLC |

San Shiah PLC |

|

MMI Touchscreen |

|||

|

Color touchscreen 6" x 2 / 10" x 1 |

Grey touchscreen 6" x 3 |

Grey touchscreen 6" x 1 |

LED Key PAD type |

|

Machine Speed |

|||

|

300 m/min (Max.) |

200 m/min (Max.) |

150 m/min (Max.) |

100 m/min (Max.) |

|

Lamination Material |

|||

|

OPP, PE, PET, PVC, CPP, Paper,AL |

OPP, PE, PET, PVC, CPP, Paper,AL |

OPP, PE, PET, PVC, CPP, Paper,AL |

OPP, PE, PET, PVC, CPP,AL |

|

Tension Range |

|||

|

3-30 kg |

3-30 kg |

3-30 kg |

3-30 kg |

|

Unwind/Rewind Diameter |

|||

|

90-800 mm |

90-800 mm |

90-800 mm |

90-600 mm |

*All specifications, dimensions and design characteristics shown in this catalogue are subject to change without notice.

*Above control system is suitable for rotogravure printing machines. Control components are provided according to customer's requirement.

*Control systems for other printing machines are available. Contact us for further details.

This is the detailed information for Extrusion System Lamination Machine Control System. The information includes model, name, description and specification for Extrusion System Lamination Machine Control System.