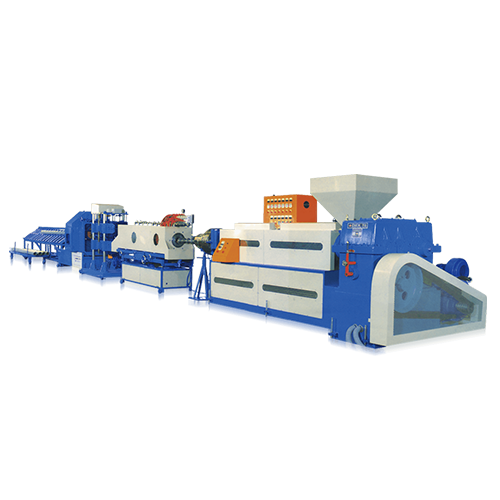

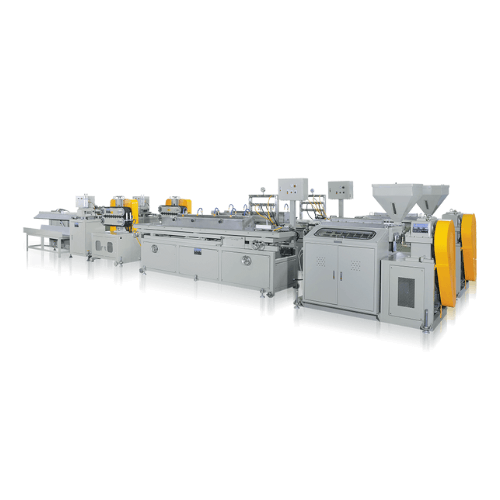

The PVC pipe making machine is a specialized manufacturing equipment used to produce PVC pipes. The machine can produce pipes of different sizes and specifications, depending on the requirements of the manufacturer. PVC pipe making machines come in different types and configurations, each designed to perform a specific function in the production process.

BENEFITS OF USING A PVC PIPE MAKING MACHINE

Using a PVC pipe making machine offers several benefits, including:

- Higher efficiency: A PVC pipe making machine can produce PVC pipes at a much faster rate than manual methods, resulting in higher production rates and increased efficiency.

- Consistency: PVC pipe making machines are designed to produce pipes of consistent quality and dimensions, ensuring that each pipe meets the required specifications.

- Cost savings: Using a PVC pipe making machine can lead to significant cost savings in terms of labor, time, and materials.

- Improved safety: Using a PVC pipe making machine can improve safety in the workplace by reducing the risk of accidents and injuries associated with manual pipe production methods.

|

Модель |

CY-50RP |

CY-65RP |

CY-80RP |

CY-100RP |

CY-120RP |

CY-150RP |

|

Модельный ряд |

3/8” → 1” |

1” → 2” |

2 → 2½” |

3” → 4” |

5” → 6” |

6” → 8” |

|

ЭКСТРУЗИОННАЯ МОЩНОСТЬ (КГ/Ч) |

20 ~ 35 |

30 ~ 50 |

40 ~ 70 |

70 ~ 100 |

80 ~ 150 |

150 ~ 220 |

The PVC pipe making machine consists of several components, including:

- Extruder: The extruder is the heart of the PVC pipe making machine. It is responsible for melting and mixing the PVC resin with other additives to create a homogenous mixture. The extruder also shapes the mixture into a pipe by pushing it through a die.

- Die: The die is a critical component of the PVC pipe making machine. It shapes the melted PVC mixture into a pipe of a specific size and shape. The die is designed to withstand high temperatures and pressures to produce pipes of high quality.

- Cooling system: The cooling system is used to cool down the PVC pipe after it is extruded from the die. The cooling process is important to ensure that the pipe retains its shape and does not deform.

- Haul-off unit: The haul-off unit pulls the PVC pipe through the cooling system to ensure that it is properly cooled and shaped.

- Cutting machine: The cutting machine is used to cut the PVC pipe into the desired length.