классификация: Этикетировочная машина с рулонной подачей

Страна: Taiwan

Телефон: +886-3-4755947 (13)

факс: +886-3-4755475

Контактное лицо: elva

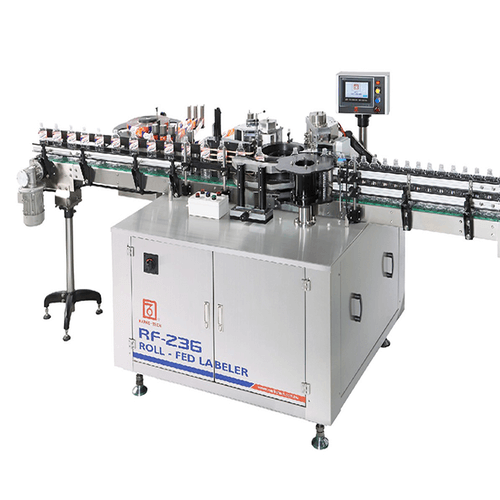

Available for 250cc~1500cc (bottle diameter 50mm~90mm) filled r un-filled round bottle shape labeling application as mineral water bottle, drink bottle, glass bottle, PET bottle, stable speed reaches to 200~300BPM.

| Round bottle hot melt OPP labeler | |||||||||

| Model/ Specification | RF-236 / H | ||||||||

| Speed | 200 / 300 BPM | ||||||||

| Model/ Specification | Round bottle hot melt OPP labeler | ||||||||

| RF-236 / H | |||||||||

| Speed | 200 / 300 BPM | ||||||||

| Bottle shape | Round bottle | ||||||||

| Ø50~Ø90mm /250cc~1500cc | |||||||||

| Label size | Width 30~150mm / Length 170~390mm | ||||||||

| Label thickness | 0.038mm~0.04mm |

- Star wheel design for input and output to make sure the bottle not feed in falling. Torque limiting for automatic stop device. Ensure smooth operation, connection, and safety.

- The overall frame is made of C-shaped steel, which has high strength and low vibration. It uses a steel wire suction pipe, which is durable, high strength, and not easily deformed by heat.

- Using high-precision gear driven, the gears are heat-treated and grounded, with high precision and low noise

- Using Italian motor reducer, long life, and high efficiency

- Core vacuum drum: After the rubber pad is worn, only the head and tail rubber pads need to be replaced, which greatly reduces the maintenance cost. The hidden suction pipe design is not easy to be damaged and beautiful.

- Cutter mechanism: The base of the cutter mechanism adopts beveled roller bearings; stable cutter holder and higher precision. No touch label cutting, not easy worn, longer life and lower cost. The gap of cutting precision can be reaching to 0.001mm, faster and easier adjustment, the cutter is made of wolfram steel, which is sturdy and durable.

- Gluing mechanism: The base adopts beveled roller bearings, the mechanism is stable, less vibration, evenly distributed glue applying quantity and the easier adjustment, low production cost.

- Feeding mechanism: By star wheel for feeding, which really drives the bottle that is not easy to fall on conveyor. The protection setting of torque limit avoids damage to the machine when bottle falling.

- Wiping mechanism: When the bottle changing, the wiping guiders can be directly replaced without any further adjustment.