классификация: ОКАЗАНИЕ УСЛУГ

Страна: Taiwan

Телефон: +886-2-8601-3839

факс: +886-2-8601-3833

Контактное лицо: Sales

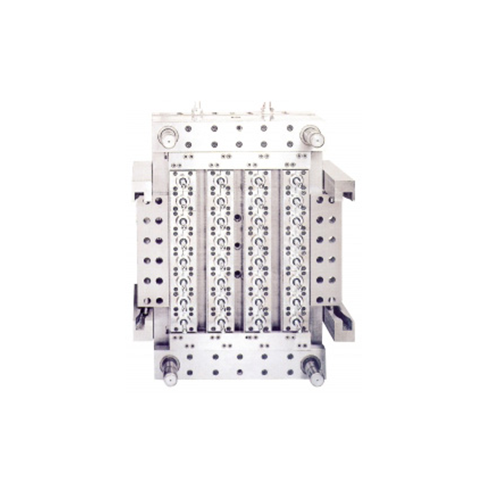

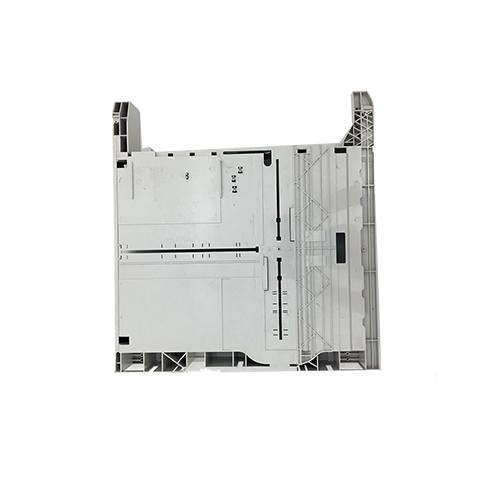

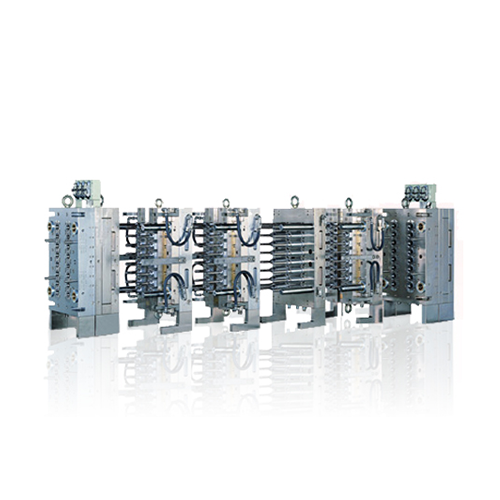

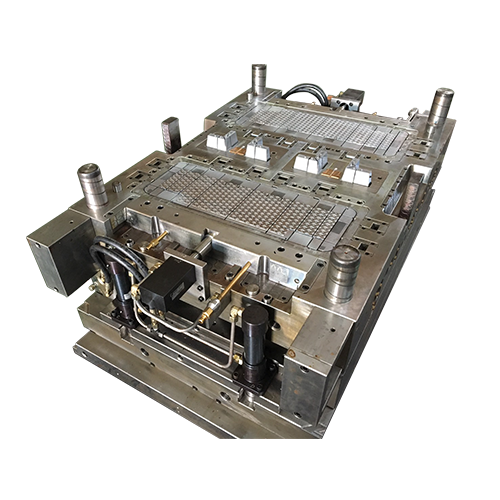

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks.

THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING :

- Micro means the size of the part. It is the most common definition when dealing with micro molding.

- Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features.

- Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding.

SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS :

- Dimension Aspect ratios around 6:1 (material dependent)

- Wall thickness : 0.3 mm ( 0.012”) min. for plastic

- Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min.

Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. - Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).