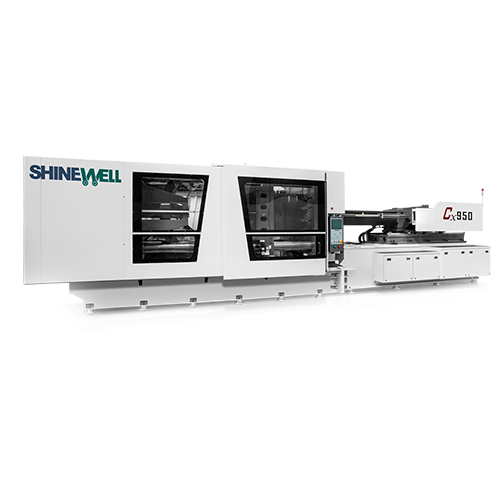

Серво-энергосберегающая литьевая машина CX-60 - CX-1600

КАТЕГОРИИ : Горизонтальные термопластавтоматы

ПРИМЕНЕНИЕ: упаковка, оптика, электроника, ПЭТ-преформы, крышки, столовые приборы, тонкие стенки, автомобильная промышленность.

Vertical Two Tie-Bar Injection Molding Machine

КАТЕГОРИИ : Гидравлические литьевые машины с зажимом

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production, then reduce the cost of production. High precision mold platen (Parallelism/flatness:0.01/100mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact, space-saving design, reduce the heavy burden of the floor of factory.

Vertical Single Shuttle Table Injection Machine

КАТЕГОРИИ : Вертикальные литьевые машины

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

Vertical Shuttle Table Injection Molding Machine

КАТЕГОРИИ : Вертикальные литьевые машины

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie-bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

Custom Vertical LIM LSR Injection Moulding Machine

КАТЕГОРИИ : Вертикальные литьевые машины

Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. Increased productivity and efficiency with shuttle table or rotary table configuration. Pick and place products while another product finsihes molding. Energy savings of around 50-70% with servo pump power system. Safety cover, Light curtain, pneumatic door and dual palm safety button for personnel safeguard. Multi-Language PC Base industrial type Linux core system. 1000 sets of mold settings can be stored and export as backup. Complete record of history settings & warnings. Built in USB connect. On-line remote control and maintenance service.

Vertical 4-TIE BAR Injection Machine

КАТЕГОРИИ : Гидравлические литьевые машины с зажимом

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

C Type Injection Molding Machine

КАТЕГОРИИ : Вертикальные литьевые машины

Tie-bar less (C type) design gives more space for operation. Especially suitable for the power cord and connector with wire. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , thus reduce the cost of production. High precision mold platen ( Parallelism/ flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitrite and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, resolve the floor space shortage problem of factory. Material injected through parting line to cavities.

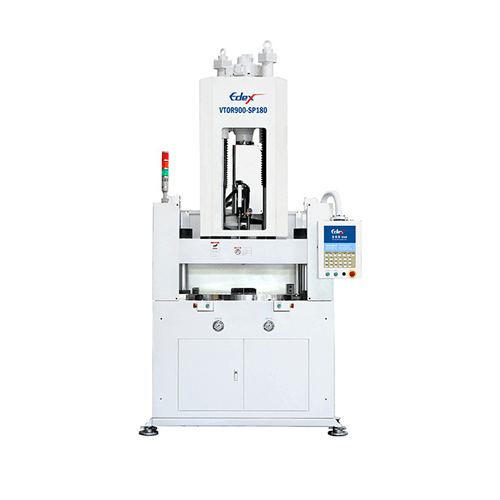

VTOR-Вертикальная ротационная машина для литья под давлением

КАТЕГОРИИ : Автоматические литьевые машины

● Наименьшая конструкция поворотного стола, максимальный диаметр пресс-формы. ● Костюмы для впрыска Плунжерного типа или системы впрыска винтового типа. ● Запатентованная конструкция вспомогательной пластиковой системы байпаса. ● 2-полосная 4-цилиндровая система прямого зажима. ● Запатентованная центральная радиальная плита прочная в течение 30 лет. ● Защитная защитная решетка. ● Интеллектуальный программный контроллер облегчает впрыскивание. ● Самая низкая машина для литья под давлением на столе. ● Точная энергосберегающая гидравлическая система.

JN Series-Double Station

КАТЕГОРИИ : Автоматические выдувные машины

● Автоматическая выдувная машина гидравлического типа. ● Автоматическая конструкция производства. ● Конструкция зажимной конструкции с большой нагрузкой. ● Mold Open / Close / Move by precision linear guide и готовые бутылки выходят в линию для следующего процесса. ● Экструдер привода коробки передач напрямую. ● Ломает централизованное управление. ● Управление ПЛК с сенсорным экраном для времени, давления, расхода и т. Д. ● Диверсифицированные ножи для заготовки и выбор нескольких головок зависят от требования. ● Система энергосбережения для гидравлической системы.

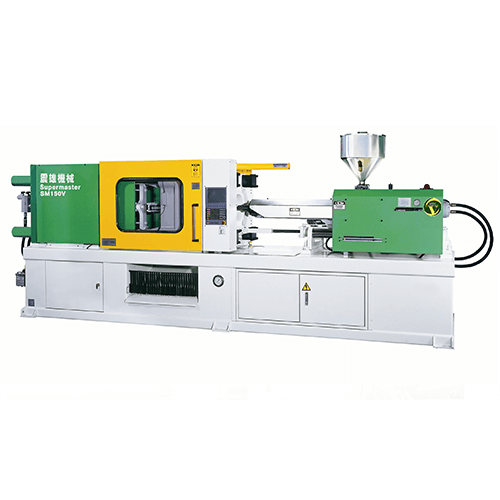

Двойная машина для литья под давлением (серия SMV)

КАТЕГОРИИ : Горизонтальные термопластавтоматы

• Конструкция с двойным цилиндром уменьшает расстояние впрыска. • Ионно-азотированные основные компоненты - бочка, винт и т. Д. Обеспечивают прочный срок службы. • Легко регулируемые и надежные многоступенчатые давления впрыска и регулирование скорости. • Стальные втулки имеют твердость HV800 для сопротивления износу. • Система автоматической смазки обеспечивает постоянную смазку переключающего механизма. • Многотактный гидравлический эжектор обеспечивает положительный выброс продукта и обеспечивает беспилотное производство с использованием или без использования роботизированной рукоятки. • Дифференциальная гидравлическая схема сокращает время цикла и экономит энергию. • Для предотвращения повреждения плесени или чрезмерного износа использовалась система защиты от литья под давлением.

Water Conditioner / scale prevent and eliminate

Water Conditioners magnetically alter the natural characteristics of hard waterminerals, making it difficult for them to bond together and form a hard brittle scale. Instead,they remain in a suspended state and will either flow on through, or can be easily purged from, water-using equipment and plumbing systems. Superior technology also has zero environmental impact because it requires no energy or chemicals to operate.

Переключить энергосберегающую машину для литья под давлением Servo 90E на Servo 570E

КАТЕГОРИИ : Горизонтальные термопластавтоматы

● Effective Energy Saving Unit ● Outstanding Hydraulics ● ASE Servo Pump