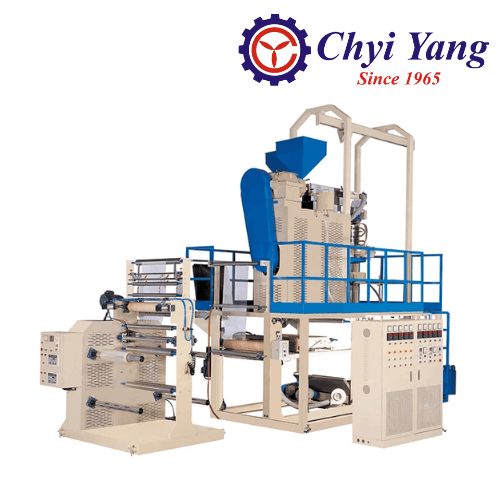

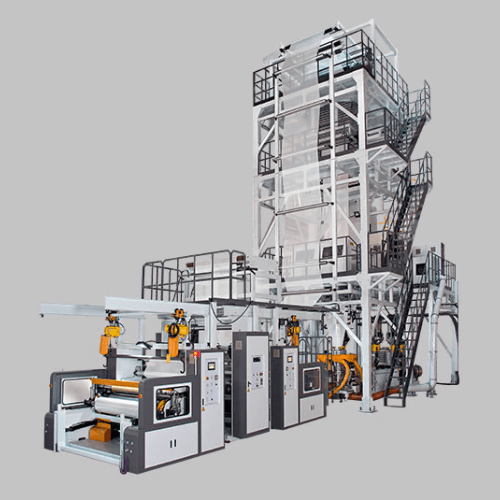

Super High Speed HDPE/LDPE/LLDPE Blown Film Machine

КАТЕГОРИИ : Экструдеры пленки методом выдувания

Barrel and Screw have special treatment and forced feeding for better output Easy installation & operation Adjusting thickness easily by screws of die, high capacity & less plastic waste Automatic flying cutter & manual change reels winder, flying cutter to match the machine speed, won’t be re-winded on the nip roller Main Motor is driven by inverter for better performance & less electricity Purchasing a LDPE/LLDPE die can produce LDPE/LLDPE film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

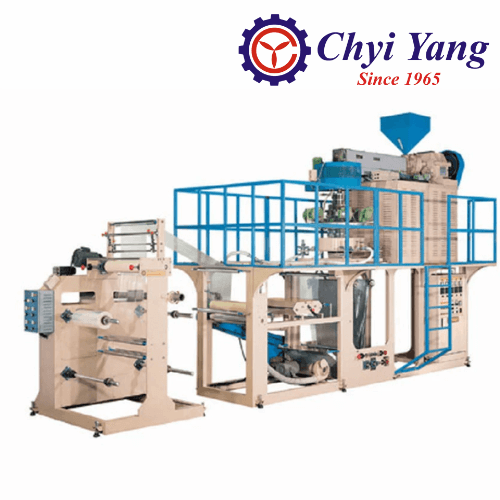

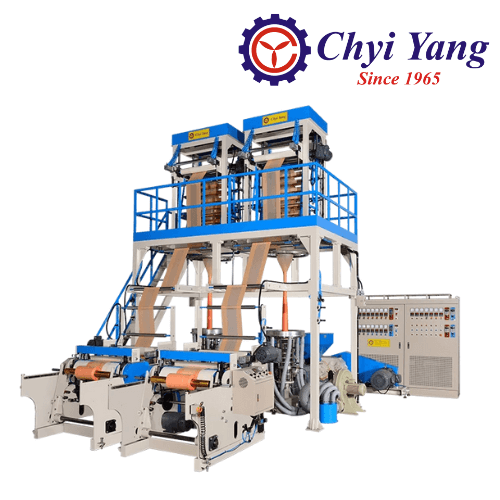

Two Stripe Color Blown Film Machine

КАТЕГОРИИ : Экструдеры пленки методом выдувания

TCP-H is designed by two independent motors, gear boxes and extruders to produce films with two colors stripes TCP-SE is designed by one motor, one gear boxes & two extruders to produce film with two colors stripes TCP-H makes width of two colors can be adjustable TCP-SE is for saving cost of machine & less capacity The precise die design makes the colors vivid, clear & won’t be mixed together Purchasing a 2-layer co-extrusion die can produce 2-layer film We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

PP Blown Film Machine

КАТЕГОРИИ : Экструдеры пленки методом выдувания

Water cooling system makes glossier and more transparent PP film for food or garment packing. Unique screw provides high production for a long period life and holds film uniformly steady. Dry chamber provides a fast water removal, for food package purpose. Optional tension control for winder provides good tension film in rolls, used in food packaging & printing. We didn’t show all our models, please don’t hesitate to contact us for bigger extruders.

Mini Type Blown Film Machine

КАТЕГОРИИ : Экструдеры пленки методом выдувания

Designed for T-Shirt bag and flat bag production Small occupancy of space Simple, flexible and economic operation High output and saving energy Also can work with LDPE resin if changing air ring Film thickness HDPE 0.008~0.06 mm

High Speed Twin Die Blown Film Machine

КАТЕГОРИИ : Экструдеры пленки методом выдувания

TDH series is one extruder provides two dies to get bigger capacity & less space. TDH-S series is standard machine. TDH-F series is forced feeding type for more output & faster speed. Purchasing extra LDPE die can produce LDPE film.

2-LAYER CO-EXTRUSION BLOWN FILM MACHINE

КАТЕГОРИИ : Выдувные машины с коэкструзией

Available for agricultural film, coated film, stretch film, cling film, greenhouse film etc. Max film width up to 4.2 m (8.4 m in single-layer-opened film) Raw material HDPE, LDPE, LLDPE, EVA, MPE etc. Two sets of gearbox, motor & extruder for independent control For producing PE stretch/cling film, PIB liquid adhesion system can inject liquid adhesion into screw directly to save resin cost & adjust the stickiness ratio you need Purchasing PIB system can produce out-layer film non-sticky to prevent dust, in-layer film sticky to pack subjects Optional “Waste film recycling machine” lets this machine doesn’t have any waste plastic film, it can feed waste film directly into screw to save your cost We didn't show all our models, please don’t hesitate to contact us for bigger extruders.

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine

КАТЕГОРИИ : Выдувные машины с коэкструзией

Water Cooling Downstream 2-Layer Co-Extrusion Blown Film Machine, CHYI YANG is Multilayer Co-Extrusion Manufacturer, We mainly produce plastic film machinery whole plant equipment and inseparably linked with the life and development of plastic machinery in Taiwan.

3-LAYER CO-EXTRUSION BLOWN FILM MACHINE

КАТЕГОРИИ : Выдувные машины с коэкструзией

Application for greenhouse sheet, agricultural films, construction sheets, food packaging, sacks, shrink films, shrink hood films, and more. Max. film width of up to 4.2 m (8.4 m for single-layer-opened films) It supports a wide range of raw materials such as HDPE, LDPE, LLDPE, EVA, MPE, PP, and others. The machine is equipped with three sets of gearboxes and motors for independent control. Optionally, a 360º Oscillating Nip roller device can be added to ensure uniform film thickness and improve the performance of the rotary die device. The machine can be equipped with a "Waste Film Recycling Machine" which enables direct feeding of waste film into the screw, eliminating any waste plastic film and reducing costs. Please note that the models shown here are not exhaustive. If you require larger extruders, please feel free to contact us.

5-слойная коэкструзионная пленочная машина

КАТЕГОРИИ : Выдувные машины с коэкструзией

Экструдер 5-слойная PE группа / Рециркулированный / PA / EVOH 5-слойная коэкструзионная экструзионно-выдувная пленка 5-слойный коэкструзионный удар

3-х слойная коэкструзионная пленочная машина

КАТЕГОРИИ : Выдувные машины с коэкструзией

Экструдер 3-слойная (ABC) PE Group / PP / Переработанная 3-слойная коэкструзионная экструзионно-раздувная машина

7-LAYER CO-EXTRUSION BLOWN FILM MACHINE

КАТЕГОРИИ : Выдувные машины с коэкструзией

CHYIYANG specializes in manufacturing 7-Layer Co-Extrusion machinery, which is utilized for producing uniform films used in various applications such as food and milk packaging, shrink film, shrink hood film, self-adhesive films and more. Our machinery is equipped with a bi-metal screw and a precision die. With over 50 years of experience in the field of Co-Extrusion, we ensure high-quality results.

ABA 3-Layer Co-Extrusion

КАТЕГОРИИ : Выдувные машины с коэкструзией

CHYIYANG is ABA 3-Layer Co-Extrusion manufacturer, ABA 3-Layer Co-Extrusion, ABA Co-Extrusion Machine, It produces uniform film for food & milk package etc. Screw is Bi-metal & precise die More than 50 years experience about ABA Co-Extrusion.