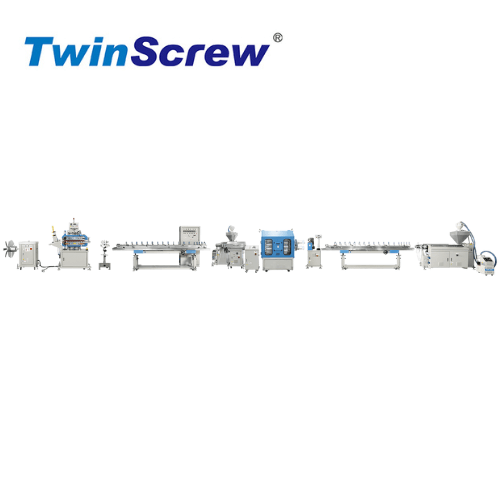

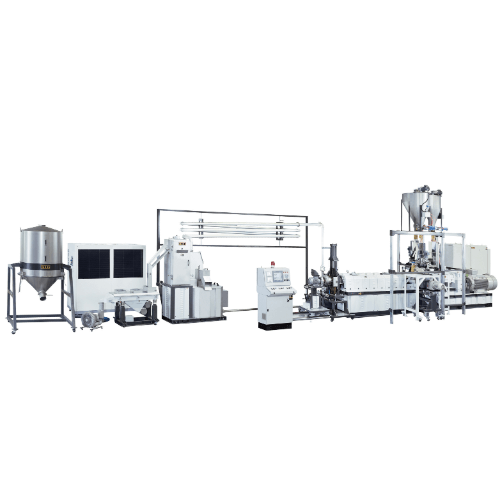

Co-rotating Twin Screw Underwater Pelletizing Compounding Line | CK-HT

КАТЕГОРИИ : Двухшнековые экструдеры

CK-HT series Co-rotating Twin Screw Underwater Pelletizing Compounding Extrusion Line is designed especially for compounding materials with high viscosity, low MI, or difficulty to be shaped. The extrusion line can be applied to a wide range of materials and applications. Possible materials: TPU, TPE, TPV, TPR, PP, PS, PLA, PVA, SEBS, EVA, Rubber, Hot-melt adhesive, Special resin, and Micro pellet, etc.

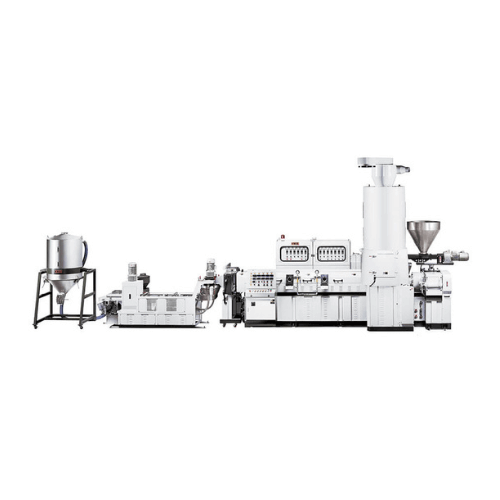

Single Screw Underwater Pelletizing Extrusion Line | CK-S

КАТЕГОРИИ : Одновинтовые экструдеры

CYKF CK-S series Single Screw Underwater Pelletizing Extrusion Line can be applied to a wide range of applications. It is especially suitable for materials with high viscosity, low MI, and difficulty to be shaped, e.g., TPE and TPR. Possible materials : TPU, TPE, TPV, TPR, PP, PS, PLA, PVA, SEBS, EVA, Rubber, Hot-melt adhesive, Special resin, and Micro pellet, etc.

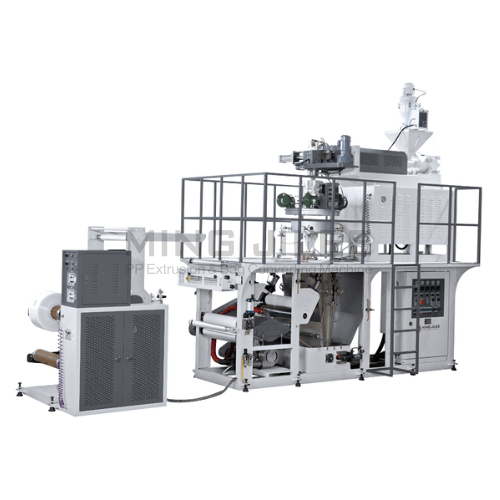

Side Force Feeder Type Recycling Pelletizing Extrusion Line | CK-SF

КАТЕГОРИИ : гранулятор

CK-SF series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic crushed films. Possible materials : EPE, EPP, EPS, PP, HDPE, LDPE, ABS, PS crushed films.

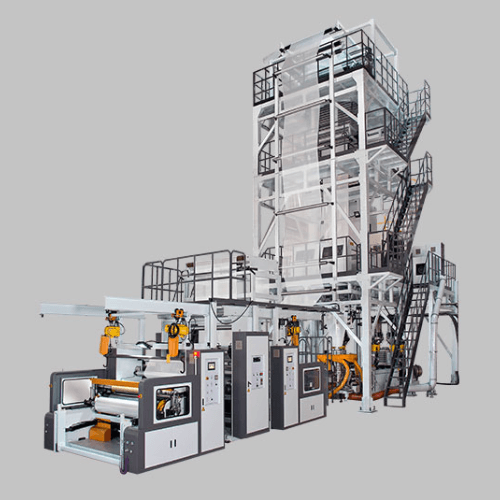

2,5-миллиметровая 10-слойная экструзионная линия для экструзии воздуха с пузырьковой экструзией

КАТЕГОРИИ : Экструдеры воздушно-пузырчатой пленки

Упаковка электронного материала с антистатической добавкой

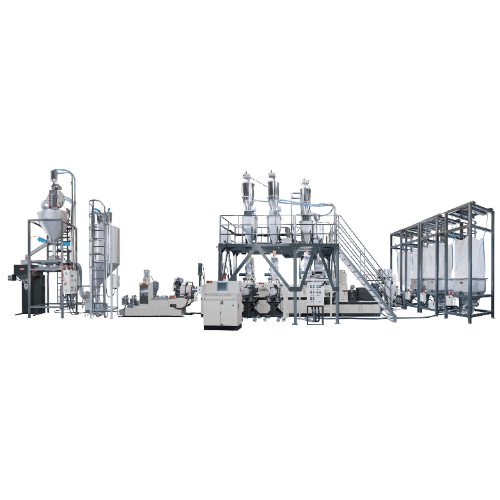

Co-rotating Twin Screw Automatic Metering / Weighing / Conveying Pelletizing Compounding Line | CK-HT

КАТЕГОРИИ : Двухшнековые экструдеры

CYKF is committed to the R&D and manufacturing of the automatic extrusion systems, and constantly strives for perfection. The CK-HT series Co-rotating Twin Screw Automatic Metering Weighing and Conveying Pelletizing Compounding Extrusion Line successfully overcomes the problem of customer limited site space and configures the optimal traffic line for customers. The high-efficiency system shows the advantages of safety, convenience, efficiency and quality, reflecting the greatest value of CYKF.

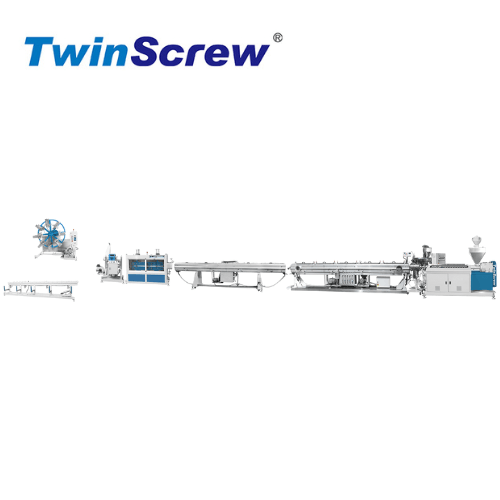

PVC Pelletizing Extrusion Line | CK-DT

КАТЕГОРИИ : Двухшнековые экструдеры

CYKF is well-known in PVC extrusion. Our CK-DT series Counter-rotating Twin Screw Extruder is especially designed for PVC. The available screw diameter is between 55 to 130mm. We never stop improving our PVC extrusion technology and we love sharing ideas with customers. Our in-depth understanding of PVC enables us to design better extrusion lines compared to other competitors. CYKF’s PVC extruder is high-efficient and durable, its outstanding performances has earned highly praises from global users.

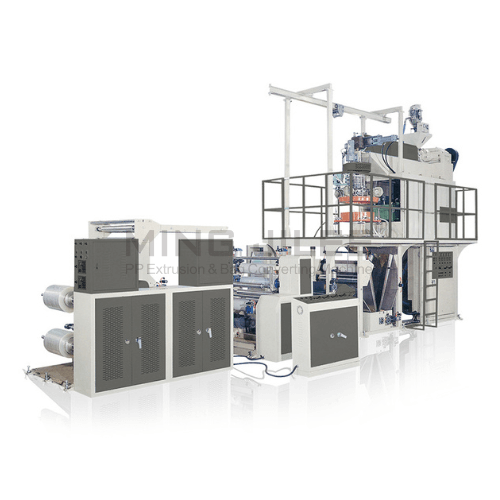

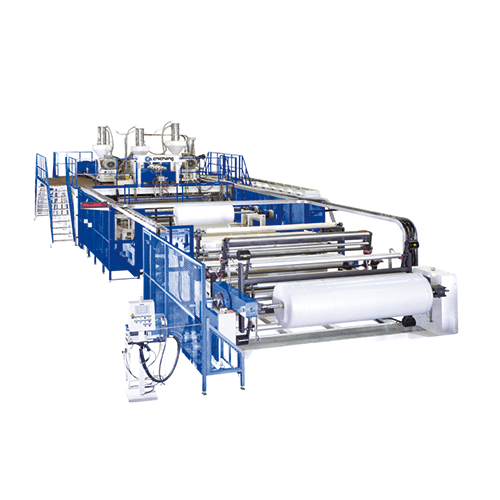

Линия для экструзии плоской пряжи PP / HDPE (для Ткани из PP / HDPE)

КАТЕГОРИИ : Экструдеры ленты

Трехслойная линия экструзионной ленты с технологией прорыва для производства трехслойных ПП-лент премиум-качества и самых низких производственных затрат. Ленты в основном используются для мешков из полипропилена и различных применений.