CHEN WAY: How is a Sports Water Bottle Made by Extrusion Blow Molding?

When we talk about everyday use products, we can mention different examples such as sports water bottles, which are in almost everyone's daily life: besides ensuring individuals stay hydrated throughout the day, they also eliminate the need for disposable, single-use bottles which are known for polluting the oceans.

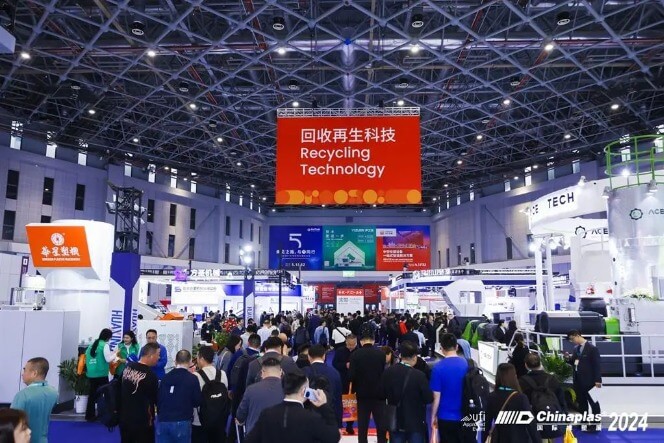

GMA: Chinaplas, a New Opportunity to Meet Customers and Showcase Latest Developments and Technologies

Last year Chinaplas was held in Shenzhen, being the second year of the pandemic the situation made the number of people relatively small in comparison with previous editions, also most of the visitors were local.

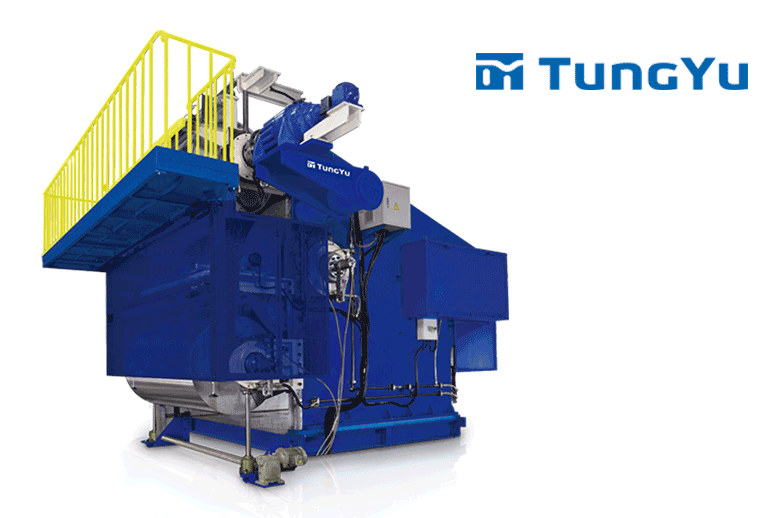

TungYu: Horizontal Rubber Injection Molding Machine

How to save material and increase productivity simultaneously? Horizontal rubber injection molding machine can contribute to reduce material waste and optimize automation. Tung Yu makes our effort to serve the best solution for customer.

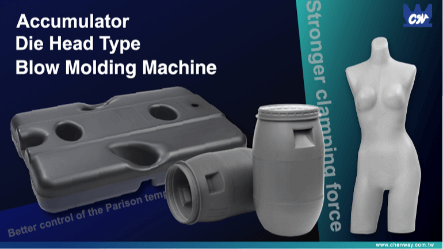

CHEN WAY - How to Select the Correct Blow Molding Material for Your Products

Extrusion blow molding machines can produce a wide variety of hollow plastic products. It is important to keep in mind that in order to produce exceptional products, besides purchasing high-quality Blow Molding Machines, it is also crucial to choose the correct blow molding material for each project. This ensures that the end products will have the desired properties and will also be able to withstand the environment(s) that they will be exposed to.

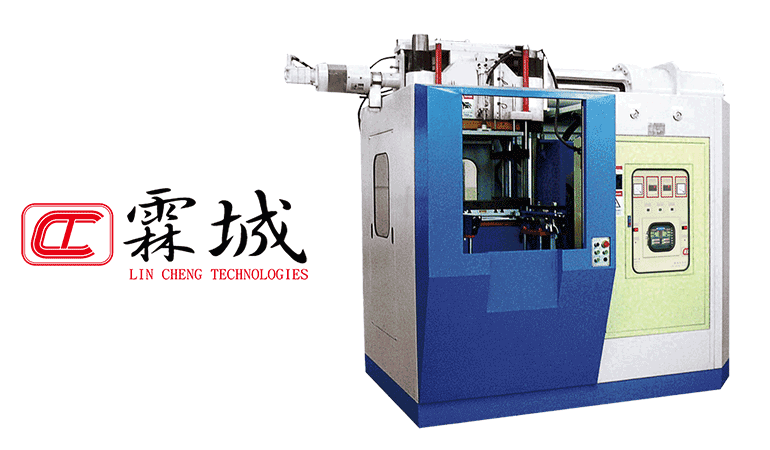

What to Expect in 2022 for LIN CHENG’s Strategy and Performance for their Rubber Injection Molding Machinery

For more than four decades Lin Cheng Technologies has shown its great expertise around the world on the run of providing Customized Solutions, Rubber Injection molding machines, Silicone rubber injection machines, vacuum hot press injection molding machines and other types of hot press injection molding machines to the Industry.

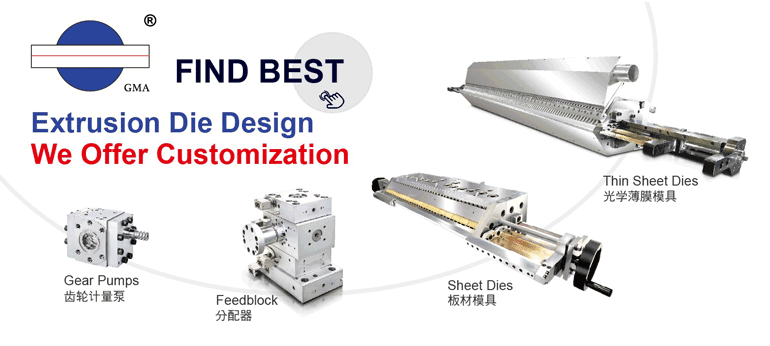

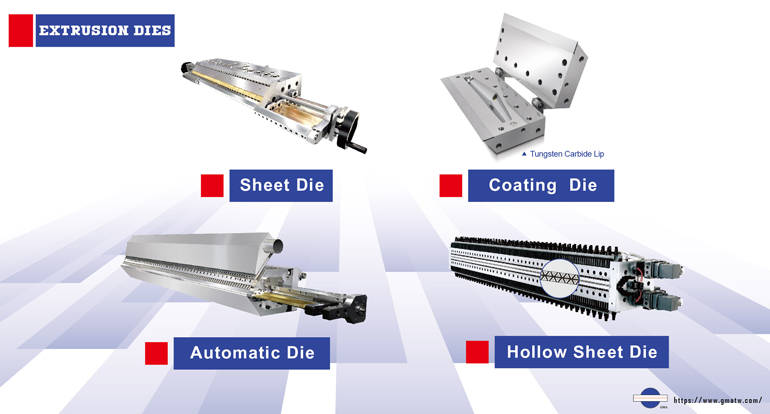

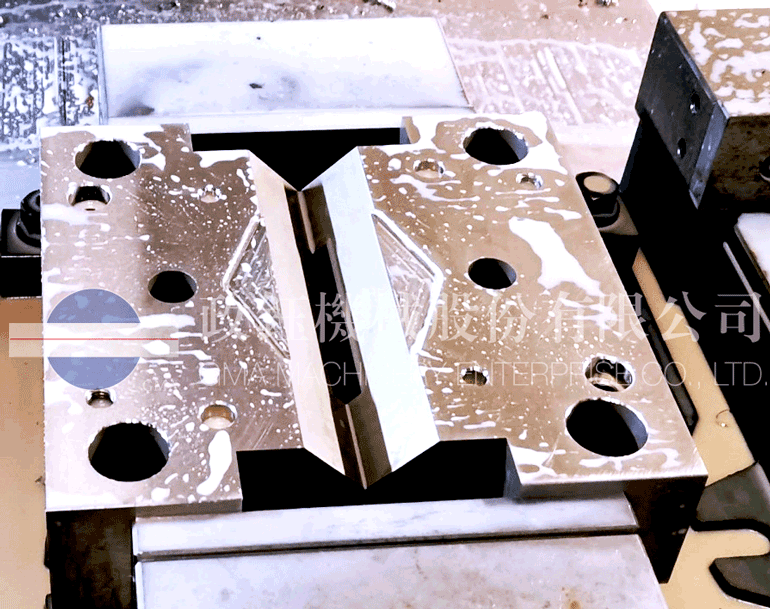

Why to Choose GMA’s Extrusion Dies?

It is well known the importance of high quality and high precision when we talk about Molds and Dies. GMA is one of the worldwide leaders of the industry, last year they became a really important actor, due the capacity of high production of Melt blown Dies, an indispensable component when it came to production of masks, which became a “must” in our daily life.

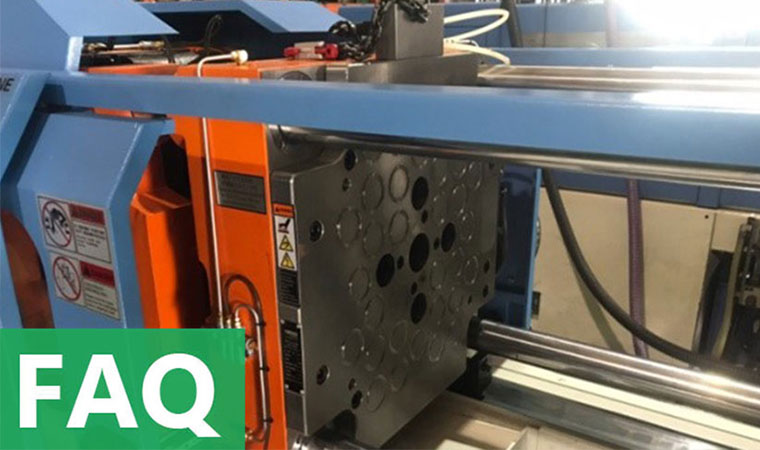

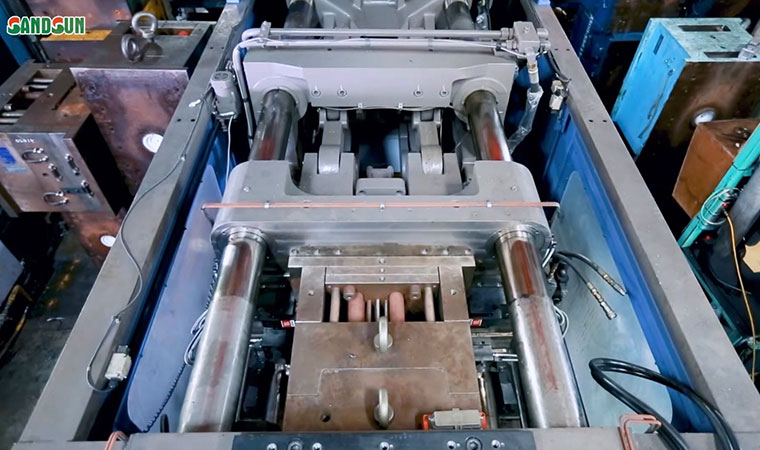

Magnetic Clamping System FQA

In the current environment, it is a good time to introduce magnetic clamping system, only need one operator. This reduces labor costs and labor consumption, and the mold change speed is faster than hydraulic clamping. The latest magnetic structure and outstanding design of magnetic circuit achieves a 20% and more of the magnetic force than traditional magnetic plate design. And SANDSUN magnetic clamping have 8 special safety function designs.

5 Tips for Efficient Injection Molding Mold Change Procedure

Regardless of the metal stamping production line or the injection molding production line, mold changing s often one of the most time-consuming procedure, and a lot of intangible waste is also generated during mold changing. In addition, in traditional mold changing process, which must rely on the master’s experience to set molds and adjust molds. However, this technical work has been gradually lost. The younger generation of employees are less willing to engage in mold changing work because this job is relatively dangerous and tired.

PLASCO MONOFILAMENT LINE & STRAPPING BAND LINE & RAFFIA TAPE & TWINE EXTRUSION LINE

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our specialty knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years.

New Milestone of GMA—HASTELLOY Processing & Application

HASTELLOY® C276 (UNS N10276, hereinafter referred to as C276) is one of alloy to be well against high corrosive chemical, such as Chloride gas、Hypochlorite、Chlorine dioxide, special to Oxidizing salt solution (such like Ferric Chloride and Copper chloride), C276 is with excellent tolerance, currently, C276 is recognized as the best alloy for anti-corrosion metal.

3 Simple Secrets for Ecofriendly and Cost Saving Blow Molding

One thing that makes blow molding so great are its endless applications. In fact, plastic products are everywhere, making it clear how incredibly useful this material is in modern life. However, in today’s world, the production of these products is not just a matter of their unit price, quality, or visual appearance; customers and end users also care about their sustainability, and they care a lot.

Cutting Machines 101 with Alber Bandknives Germany

Because they are so commonplace, cutting machines are often overlooked. They do not require the chemical expertise of continuous foaming, but they are still a school of knowledge unto themselves. Sunkist has decided to collaborate with Alber Bandknives Germany. We’re bringing you expert knowledge about cutting polyurethane foam from both the machinery end and the blade end.

GMA Successfully Overcome 2021 Challenges, and Ready to Continue Giving High Quality Service to the World

This year was though for Taiwanese companies due the outbreak of COVID-19, but for GMA was an opportunity to continue growing on different markets, such as China which is one of its main markets, also it is important to mention that GMA has established at the vanguard in different regions, such India, but also High-End markets such as Japan and Europe...

TUNG YU: Rotocure with CE Certificate

Continuous vulcanizing process provides high production efficiency and stable quality. Auto latching chuck for safety and promptly loading/unloading material shaft. Control system by PLC and HMI to easily and precisely set up temperature, pressure, speed and other production parameters.

CHEN WAY - Top 6 Common Problems in HDPE Blow Molding

HDPE Blow Molding is the most economical- highest production output forming process for hollow products: beverage, chemical or pharmaceutical bottles, edible oil jerry cans, chemical drums, etc. And even though you can produce an almost perfect, high quality container, you might encounter different problems along the blow molding process of your products, so it is vital that you can identify where the problem comes from and how to handle it.

GMA at Chinaplas 2021, Reaching Customers During Pandemic Times

This year, 2021, has been open to speculations about what is going to be the economic performance and how different industries are responding to pandemic times. After 1 year without international exhibitions, Chinaplas was the first big exhibition of the industry, therefore all the main players were waiting for the results.

TUNGYU- C Type Injection Molding Machine with Rotary Table

With C type configuration to have easy operation access. Rotary table design with two molds shifting to increase production efficiency. Feeding rupture detect to prevent process from rubber shortage. With external heating platen to maintain mold temperature.

3 Reasons to Invest in PU Continuous Foaming

We’ve talked about why a plant might invest in batch foaming. What about continuous foaming? The biggest reason people avoid investing in a continuous foaming set-up is, of course, the cost. Not only is a machine like the SA-1AF pretty pricey ($450k+), but you also have to have the space, accessories, and ancillary equipment to make sure your continuous foaming machine is running at peak efficiency.

LIN CHENG: High Quality Rubber Injection Molding Machines, with Worldwide Sales Channels!

Lin Cheng Technologies, is one of the leaders of the Industry, with more than 4 decades of experience and with good worldwide reputation, thanks to the well-known quality of their machines.

3 Reasons to Invest in PU Batch Foaming

Did you know that in 2021, industry giants are investing more than ever in manufacturing infrastructure? The global pandemic has slowed the polyurethane foam goods market, so in a time of less demand, many companies have opted for internal investments in machinery and factory planning.

Launching the Sunkist Mobile Workstation

2020 has unfortunately been the year of COVID. The pandemic has had different levels of impact on people around the world, but what we can say for sure is that, on the whole, social distancing has become a quintessential part of all our lives.

3 Takeaways for the Foam Industry after COVID

So the vaccine is out, and the end of COVID is coming. As the world returns in steps and strides to pre-coronavirus standards of operation, you may be wondering—what should I do? Simply pick up where I left off? Or has the pandemic impacted the foaming industry enough to necessitate change on my end?

PLASCO MONOFILAMENT Line & STRAPPING BAND LINE & RAFFIA TAPE & TWINE EXTRUSION LINE

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our speciality knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years.

KING'S - Trend In Global 5-Gallon Water Bottles Market By 2026

According to the forecast of BlueWeave Consulting, the valuation of the global 5-gallon water bottle market will increase from US$7856.88 million in 2019 to US$10,234.50 million in 2026. During the forecast period from 2020 to 2026, the compound annual growth rate is 2.2%.

CHEN WAY: 5 Minutes to Know HDPE Blow Molding

What is HDPE Blow Molding? HDPE Blow Molding is the process of molding a softened thermoplastic hollow form called a Parison. This Parison is first vertically extruded from the Die Head of a Blow Molding Machine and then, it is inflated against the cooled surface of a closed mold, the expanded plastic then solidifies into a hollow HDPE product that needs none or very little finishing processes after the Blow Molding.

GMA to Showcase the Latest Trends in Extrusion Dies During Chinaplas 2021

When it comes to machinery and peripherals such as extrusion dies, one of the first things that come to manufacturers minds is how to solve a need. In other words, when you want to purchase something, you are looking for a solution for a problem or a need, GMA’s extrusion dies are well known for fitting different needs, thanks to their capacity of adaptability to produce a wide range of products that make them always be at the vanguard in the industry.

Advantages of using Extrusion Blow Molding Machines: Your Best Solution for Aquaculture Fish Farming Floats!

Blow Molding machines have many advantages when it comes to making hollow plastic products, and especially for large hollow plastic products they are really your best solution. As an example, one very popular and common application of Blow Moulding for large products is the molding of Paddle Wheel Aerator Floats and Gear Box Covers for Aquaculture; these floats are used in Fish Farming to hold the Paddle Aerators Wheels that give the fish the oxygen they need from the environment for respiration.

KING'S - How Innovation in 5 Gallon PET Preform Production Line Save Time and Reduce Cost

An automatic customized PET Preform Production Line is the key to save cycle time, energy, labor and leads to high quality, cost-effective result for 5 Gallon Bottle Making...

TUNGYU-Medium Injection Molding Machine

TIP-1000-2RT-L-250-PCD Clamping force : 250 tons Injection Volume: 1000 c.c. Hightlights: 1. Stable output and synchronization by four injection cylinders design with double open side movement. 2. Vertical structure design with screw, piston and barrel in line to have straight compound flow with less pressure loss. 3. FIFO design with latest compound injection could have stable product quality. 4. Less remnant in feeding tube could save compund in purge. 5. Multi-stage pressure control system and accurate compound calculation for variant molding.

PLASCO MONOFILAMENT LINE & STRAPPING BAND LINE & RAFFIA TAPE & TWINE EXTRUSION LINE

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our speciality knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years.

iTungYu Horizontal Injection Molding Machine TIP-1000-H-200-PCD

How to save material and increase productivity simultaneously? Injection molding machine for rubber or silicone products to helpfully decrease material wasting and automation optimizing. Tung Yu make our effort to serve the best solution for customer

GMA: Covid-19 Outbreaks to the Whole World, Medical Supplies Become Indispensable Poperies to Every Country, such like Protective Clothing, Gown, Goggles, Protective Mask, N95 Mask etc.

In past 3 months, GMA received a lot of MB die inquiries from many countries, not only die, including gear pump and filter which can be used on melt blown fabric production line. Melt blown fabric is mostly used for mask and protective clothing, or filter.

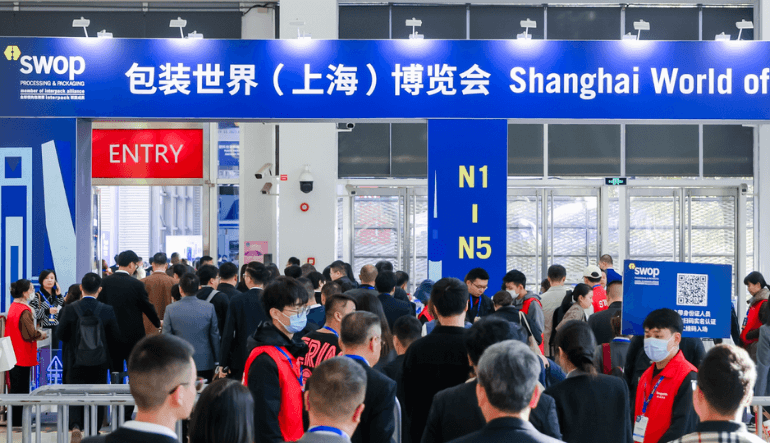

swop 2024: Leading Innovation in Packaging — A New “Buyer’s Perspective” Experience to Launch This November

The Shanghai World of Packaging (referred to as “swop”), co-organized by Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd., is set to return in full force from November 18-20, 2024, at the Shanghai New International Expo Center.

Shanghai World of Packaging (swop) 2024 – Visitor Referral Program

Shanghai World of Packaging (swop) 2024 will take place in 18-20 November 2024 at the Shanghai New International Expo Center (SNIEC). As the grand finale of this year's packaging expo, we want to help you seize this last opportunity to enjoy generous rewards and endless surprises. Whether you want to make the most of swop 2024 or start planning your upcoming business and production plans, we've got you covered with wonderful offers and inspiring ideas.

It's Record Breaking! 211,928 Visitors for the First 2 Days!

CHINAPLAS 2024 welcomed a record breaking of 211,928 visitors for the first 2 days. Among them, 44,242 came from overseas, comprising approximately 21% of the total visitors. Day 2 alone witnessed 118,687 visitors, marking a new height for single-day attendance. Of these, 24,862 were overseas visitors (~21%), establishing another new record for the daily overseas visitor no.

New Productive Forces” to Bring Plastics & Rubber Industries to New Heights CHINAPLAS - Ready to Roll at Shanghai Kick-off Gala

After a 6-year absence, CHINAPLAS, the world‘s leading plastics and rubber trade fair, is ready to make a strong comeback to Shanghai on April 23-26, 2024, at the National Exhibition and Convention Center (NECC), Hongqiao, Shanghai, PR China. To mark this special occasion, CHINAPLAS - Ready to Roll at Shanghai Kick-off Gala was held in Shanghai on March 28. More than 160 industry representatives attended the event in person and over 10,000 industry players participated online to witness the thrilling moment, sailing through high winds toward a brighter future together.

The Largest Fair in the European Region Makes a Name for Itself

Plast Eurasia Istanbul 2023, the 32nd International Istanbul Plastics Industry Fair, was held at Tüyap Fair and Congress Center in Istanbul, on November 22-25, 2023. The largest technology, innovation and information sharing, and also a giant trade platform for the plastics industry, the Plast Eurasia Fair once again maintained its position in the industry.

Eterlong: Pioneering the Future of Blown Film with Advanced Processing and Specialized Knowledge

Advanti Co., Ltd, a leading company in the titanium metal processing industry, and Hsin Long Thread Rolling Machine, a renowned Taiwanese manufacturer specializing in blown film components and die head design, are thrilled to announce their merger. This union has given rise to Eterlong, located in Tainan, Taiwan. Eterlong is an innovative brand dedicated to delivering comprehensive solutions in the blown film industry by harnessing advanced processing technologies and specialized knowledge.

ColorForward™ Predicts 2024 Trends of More Harmonious Colors with a Splash of Exuberance

Avient Corporation today announced the release of ColorForward™ 2024, the annual color forecasting guide for the plastic industry developed by its ColorWorks™ team. Now in its 18th edition, the forecasting guide includes a palette of 20 colors and effects selected by a group of color, marketing, and social trend experts. This guide is created annually to help plastic product designers, brand managers, and marketing professionals make more informed color choices.

DuPont Showcases DuroptixTM Products at GILE2022 with Debut of its Chinese Name “杜乐新”

DuPont highlights its DuroptixTM products, highly reliable silicone materials solutions for commercial and automotive lighting applications, Mini/Micro LED as well announces its Chinese brand name for the first time. DuPont also showcases the molded epoxy resin at the exhibition.

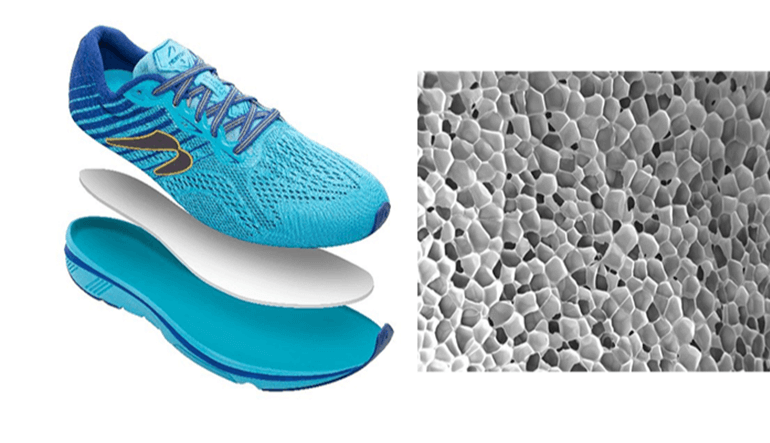

New Recyclable Hytrel® Foam from DuPont Improves Resilience, Eliminates VOCs

DuPont Mobility & Materials today announced the commercial availability of new closed-cell Hytrel® foam created via a supercritical fluid (SCF) foaming process. This fully recyclable material is the first foamed product in the Hytrel® product family.

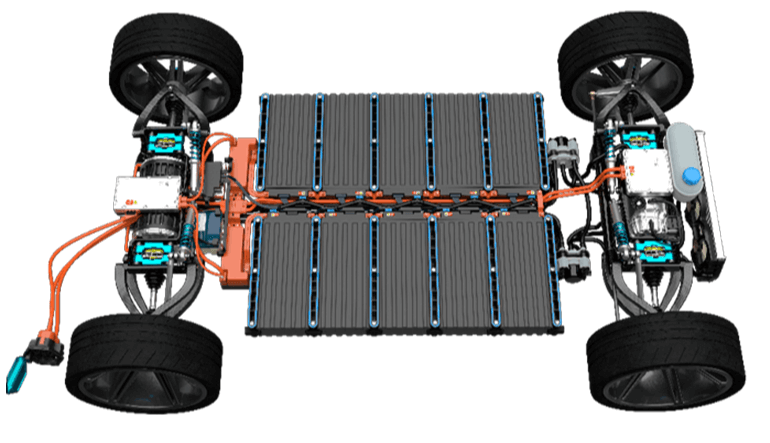

DuPont Streamlines Bus Bar Overmolding for xEV High Voltage Components with Material-Process-Service Solution

DuPont Mobility & Materials is breaking new ground for manufacturers of xEV components with a combined material-process-service solution for overmolding bus bars with Zytel® HTN material. Bus bars are a workhorse component essential for distributing power in xEV batteries, motors, and power electronics.

New DuPont™ eCool Technology Delivers Performance and Sustainability for EV Cooling Lines

DuPont Mobility & Materials today introduced new eCool technology for extrusion of multilayer cooling lines positioned inside and outside the high voltage battery pack.

DuPont Sets New Standards for Functional Sustainability with Hytrel® ECO B

DuPont Mobility & Materials today unveiled new Hytrel® ECO B, a range of bio-based TPC-ET thermoplastic elastomers. Developed to help customers improve the environmental footprint of their products, Hytrel® ECO B grades deliver performance equivalent to those made from fossil feedstock, but with biomass content up to 72% by weight.

Solvay Doubles PVDF Capacity in China Ahead of Schedule to Meet Growing Demand for EV Batteries

Solvay continues to extend its leadership position in the global lithium-ion battery market with the early completion of its PVDF capacity increase in Changshu, China. The Group has now more than doubled the onsite production volume of its high-performance polymer Solef® polyvinylidene fluoride since mid-May 2022.

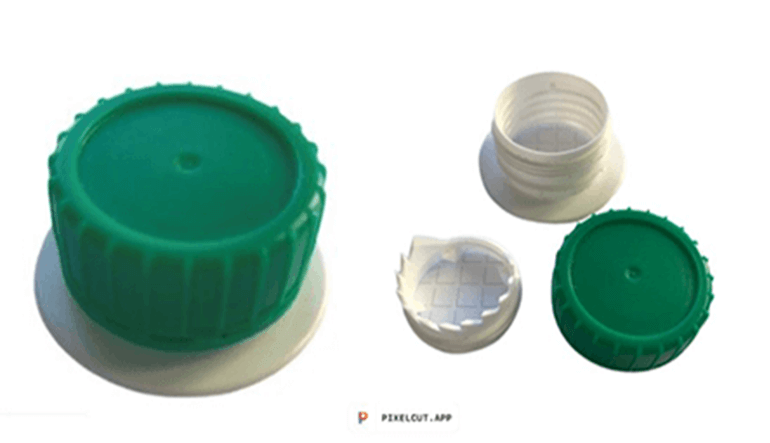

Mold-Masters E-Multi Auxiliary Equipment Provides Molder with the Capability to Maximize Productivity

The customer estimates that the time to complete the injection and assembly process has been reduced by about 50% as a result of this new system. The shrinkage occurs to all three parts evenly after assembly leading to extremely high tolerances and excellent part quality.

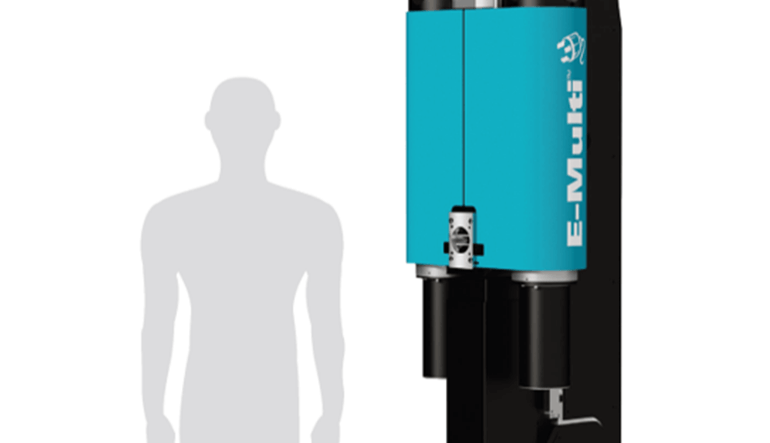

MOLD-MASTERS® EXTENDS THE CAPABILITIES OF OUR E-MULTI AUXILIARY INJECTION PLATFORM BY INTRODUCING OUR NEW LARGER CAPACITY EM5 MODEL

Mold-Masters is proud to announce the introduction of our largest capacity E-Multi, the EM5. E-Multi is an all electric, servo driven auxiliary injection unit that offers proven precision, repeatability, versatility, and reliability.