Taiwan’s resource recycling and innovation policy | PIIF

講者:環境部 資源循環署 賴瑩瑩 署長 學經歷:國立成功大學環境工程學系畢業,專職服務於環境部,曾擔任前行政院環保署廢棄物管理處處長暨前資源循環辦公室主任。 自112年9月行政院環境保護署改制為環境部,同時成立資源循環署為三級機關,主責推動「資源循環零廢棄」,目前業務重點為訂定「資源循環促進法」,本場專題演講將著重分享塑膠項目的推動重點。 -資源循環產業的低碳轉型 -推動塑膠資源循環 -循環減碳技術專案分享

Asia-Pacific Offshore Wind Power & Wind Turbine Blade in Taiwan | PIIF

引言人: 經濟部招商投資服務中心 郭肇中 總稽核 報告人:天力離岸風電科技(股)公司 王柏棋 技術處長 《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台 塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

Plastic Continuous Thermoforming Machine - Automatic Cup Lids Machine | CHUDONG

Continuous Plastic Thermoforming Machine For Cup Lids | SL-1220A from CHUDONG MACHINERY High-rigidity design of machine bed: Integral casting design combined with high-tension steel plate structure offers steady and low noise operation. 4-column high-rigidity guide-rod mechanism: Guide-rods are made of top-grade steel, offering high repetitivity of mold clamping in combination with the 4-column mold structure for steady forming. Servo chain feeding system: Japanese chain operated by servo-controller ensures exact precision of high-speed feeding. Precision Temperature Control System: Independent temperature control with the respective settings for each temperature zone uses SSR with PID calculus for controlling the temperature, combined with high-speed transmission and control, offers precision adjustment, and is convenient for elevated yield. Upper and Lower Heating Oven: German-made ceramic heater, temperature accuracy can be controlled very well. Automatic Lubrication System: Automatic oil feed for slide parts, eliminating any failure resulting from insufficient lubrication. Applications: Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on

G Series Biorenewable TPU Resins | Greco

ISOTHANE® G Series Biorenewable TPU Resins are high performance environment-friendly TPU based on renewable materials with various bio-based content. They exhibit excellent transparency, mechanical properties, abrasive resistance and solvent resistance. ISOTHANE® G series can be processed by extrusion and/or injection molding. #Bio TPU #Bio-based material #recyclable material #Use recycled raw materials #environment #ESG

Innovative applications of thermosetting and thermoplastic materials | PIIF

長興公司熱固與熱塑材料在前瞻高值領域的創新應用 講者:長興材料工業(股)公司 李全能 部長

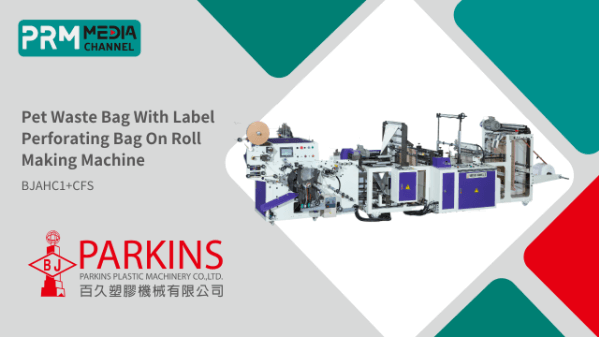

Pet Waste Bag With Label Perforating Bag On Roll Making Machine- BJAHC1+CFS | PARKINS

Model: BJAHC1+CFS Demonstration size: 20” Remarks: Designed for production efficiency and precision, this machine integrates advanced automation technology, enabling stable production at high speeds while ensuring accurate label placement on every bag. With a user-friendly interface, it is easy to operate and has low maintenance costs, making it an excellent choice for businesses requiring mass production of eco-friendly bags or garbage bags. This model can be customized to meet various needs, catering to the diverse application scenarios of our clients. For further information, please don't hesitate to get in touch with us.

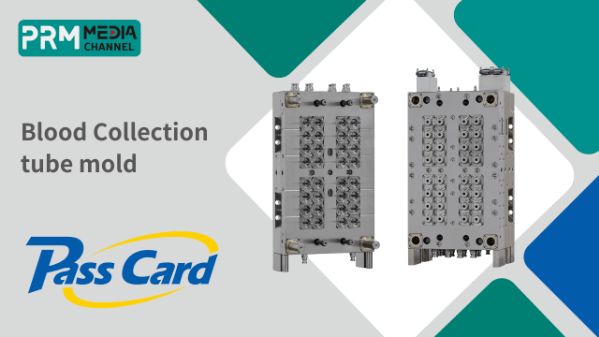

Blood Collection tube mold | Pass Card

We specialize in the manufacturing of high-quality plastic molds, with expertise in both medical applications and food packaging solutions. In the medical mold sector, we have extensive experience in producing PET blood collection tube molds and a wide range of other precision medical molds. For food packaging systems, our expertise covers in-mold labeling (IML), thin-wall molds, PET preform molds, and molds for caps, closures, and cutlery, among other applications. In the video demonstration, you will see a PET Blood Collection Tube Mold 32cavity on ARBURG 820H. With Side entry sorting & packaging automation system Please feel free to contact me anytime, Mr. Johnnason PAI +886 938198676 (WhatsApp/Wechat)

Development of key components for renewable energy | PIIF

再生能源關鍵零組件開發 講者:塑膠中心 技術研究發展部 童啟哲 博士 ● 台德國際合作-雷射固接纏繞中空管件 ● 台日國際合作-小水力複材水輪機

Plastic Thermoforming Machine - Fruit Container Box Machine | CHUDONG

Plastic Thermoforming Machine for Fruit Container Box - RMD 800from CHUDONG MACHINERY European design, intelligent control, lightweight. Convenient mold change, quick, suitable for smaller quantities and diverse production line manufacturing. High rate of movement, low failure rate, reducing the costs associated with machine errors. Innovative intelligent system, which gives the operator an easy to use interactive interface which reduces the opportunity for human error. Remote obstacle monitoring and instantaneous data processing allow rapid problem correction. High-precision cutting technology, allowing high-speed control, low machinery wear, and exceptional cutting performance. Adjustable, automatic stacking technology, which remembers your last production needs. Applications: Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on

Automatic Rotary Sealing machine(Bowl/Cup) Manufacturer | ET-80L3D8 | YF-SUPER SEALER | Y-FANG

Y-Fang Automatic Rotary Sealing Machine (ET-80) is designed to provide seamless and efficient sealing for bowls and cups. This advanced machine offers a fully automated process, from product loading to precise sealing, ensuring a secure and airtight finish every time. Its compact design is ideal for businesses seeking to maximize efficiency while maintaining high standards of hygiene and product quality. With easy operation and robust construction, the ET-80 is the perfect solution for streamlined packaging in the food and beverage industry. Application ✔️Suitable for beverages, Pudding, Jelly, Fast-food, Snacks, Various prepared foods for the microwave, Seasoned frozen food, Pickled foods, Seafood, processed agricultural products, etc. Which load into the cup and tray. ✔️Sealable material: PP, PE, PS, PET, HDPE, EPS, PSP, Aluminum foil, Paper box, etc. ✔️For smaller working spaces but higher capacity. Y-fang Group was established in 1985, specialize in the design and manufacture of sealing machines for various industrial applications. With over years of manufacturing experience, we are able to produce a wide range of tray sealing machines with a capacity of 450 to 600 pieces per hour. Our machines can perform a variety of different functions such as auto-dropping, piston filling, date printing, vacuuming, and gas flushing (MAP: Modified Atmosphere Packaging). Furthermore, we are also able to provide our customers with OEM, ODM, and OBM manufacturing solutions. Our products have been exported to countries over the world, including Europe, Asia, Africa, and America.

Medical spiral tube extrusion machine line (double output ) | Everplast

Medical spiral tube extrusion machine line (double output ) The medical tube, made by food-grade materials, with the advantage of high transparency, good elasticity, good fluidity and corrosion resistance, suitable for medical, pharmaceutical and food production of gas and liquid delivery pipes, etc. -Contact Info: Twitter: / everplast Facebook: https://reurl.cc/r1LZb Web: https://www.everplast.com.tw/ Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

Company Profile of Parker Plastic Machinery | PARKER

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

PA/PET Monofilament Extrusion Line (JC-MNN) | PLASCO

PLASCO's JC-MNN series of extrusion lines utilize a dual-stage drawing/single-stage heating process to produce high quality PA6, PA66, PET or PP monofilament extrusion line. 【Product Spec】 Applicable Materials: PA/PET Screw Diameter (mm): 50 / 55 / 65 / 80 Filament Diameter (mm): 0.12-1.00 / 0.12-3.50 / 0.50-3.50 Extrusion Capacity (kg/hr): 35 / 50 / 75 / 120 【Application】 Rope Toothbrush Longline monofilament Fishing line Tennis strings Fishing net 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Product Enhancement Through In-mold labels & Heat Transfer Films | XIANG IN

Have you ever wondered that your products do not look good and attractive? There is a simple way to enhance your product outlook and increase the quality and profitability. Throughout the interview with Ms. Penny, General Manager from XIANG IN ENTERPRISE, we have discussed advantages by using in-mold labels and heat transfer films to level up your products. Moreover, both of these two techniques not only be used in plastic, but also apply on wood, glass, metal and some particular materials. XIANG IN has been dedicated to developing its technique and improving their inspection. Therefore, the competitiveness of their products could not be replaced due to their strength of expiration and accurate quality inspection.

5G PET Preform Turnkey | KING'S SOLUTION

5G PET Preform Turnkey - 5 Gallon PET Preform Injection Molding Machines & Whole Plant Turn-Key Solution-pet-King's Machinery. FEATURES Select from 2, 4 or 8 cavities mold specifications. Single mold, 4 cavities design. The 2 stage material feed system raises the repeatability rate, lowers the cycle time, and boosts performance. When combined with a secondary cooling system, performance can be doubled. Temperature control via TSR raises temperature accuracy and, working with the accumulator, increases injection speed. Unique economical design is twice as energy efficient as comparable commercial units. we offer a complete set of 5 gallon PET bottle manufacturing equipment: raw material dehumidification and drying system; fixed-volume color additive; quickly stabilizing PET bottle preform molding machine; 4 cavity, hot runner mold; rapid cooling robot; and bottle blowing machine. From raw material to finished product stages, this all-inclusive system promotes high productivity, low cost, and superior quality-the bottle blowing defect rate is kept to a minuscule 0.5%. When water is shortage and lack of quality sanitary sewer, therefore, water container or bottle is convenience to filling in clean water and to carry with to the public. Moreover, bottle is not only for water-use but also oil-use even other liquid-use. King's gallon-size pre-form is one of the best choices in worldwide. Not only does save 20% of shipping cost but also decrease defect of blowing rate down to less 0.5%. And the most critical point is that any color is so clear by King's latest technology and 20 years PET knowledge.

Film Extrusion Equipment at K 2022 | GMA

It was a great honor for PRM to interview the General Manager — Howard Chao from GMA Machinery. He shared his insight about how the Russo-Ukrainian War affected Europe Energy Policy and the European market. He's also looking forward to having cooperation opportunities with new partners. For more information, check the video!

JAW FENG MACHINERY | PRM Media Channel Interviews at TAIPEI PACK 2020

PRM Media Channel glad to share our recent interview with JAW FENG MACHINERY at TAIPEI PACK 2020. Ms. Mary Kuo shared deep insight into the packaging industry not only for the Taiwanese market but also the global market. She mentioned the effects of the pandemic on the vacuum packaging machinery industry specifically. She also shared with us how the companies are affected based on their sizes. TAIPEI PACK is a prestigious exhibition for JAW FENG MACHINERY, the company attends the exhibition every year at the same booth location and showcases many different vacuum packaging machinery customized based on the various needs of the customers. We suggest that it is worthy to take a look at the interview video. Your opinions and questions are most welcomed in the comment section. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

Extrusion Die - Foam Die For Multi-materials | GMA

Extrusion Die - Foam Die For Multi-materials | GMA Offers a variety of extrusion die. GMA MACHINERY ENTERPRISE was established in 1989. GMA specialized in extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer. To meet extruding processor requirements, in 1990, GMA became involved in T-die design and manufacturing for sheet, film and coating film production. Over the years, we have invited several high molecular masters and doctors to research and develop various T-die manufacturing technology. GMA extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer, GMA products have been sold to worldwide markets, such as: the U.K., Japan, the U.S.A., Italy, Brazil, Argentina and China, etc. We can offer best quality which can reach American and Japan level.

Surface Modeling 3D Printing | time lapse | Everplast

Surface Modeling 3D Printing | time lapse | Everplast ①The EM3-3505-CMT is an industrial pellet 3D printer manufactured by Everplast from Taiwan. ②This 3D printer is able to utilize compound cement raw material to build products or samples. ③The standard formulation database and material bank are provided along with the 3D printer.

SUNKIST CHEMICAL MACHINERY | Interview at K 2019

We are pleased to interview Willie Huang from SUNKIST, a company from Taiwan with a great reputation for producing the machinery required for flexible and rigid polyurethane foam. This time Mr. Huang gives us a brief introduction of the company and how they are developing new machines that fulfill the new trends in the market, also making emphasis on their social responsibility with the environment. He mentions how Sunkist is facing the current challenges, such as Global warming, giving examples of how the industry is working in plastic reduction. Also, we get their new machinery introduction during K 2019, for more details please click the info card on the video or visit our B2B Platform.

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

Accumulator Blow Moulding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. Detail Specifications : The Abl Series Blow Moulding Machines Are Particularly For Producing The Jerry Can/Drum Tank/Large Article Produtions.It Can Be Combined With Some Accessory Equipments To Increase The Efficiency And Expand The Functions, Such As: After Cooling Unit/Auto Deflashing Unit. The Die Head Can Stock The Melting Resin And Purge The Material For Blowing Formed It Designed With Two Heart Flow Chnnels.Can Make Welding Line-Free To Increase The Strength Of Production. The Tie Bar-Less Clamping Unit Is Consist Of Stiffness Structure Frame And Guiding Devices.Make Sure Deflection-Free Advantage. Also Devise With Precision Rack GgearsO of Bboth Side.Make Synchronize Moving Of Plates. The Blowpin Unit Is Designed For Production Calibrating. That Will Be Suited For Different Demand Of Customer. Accumulator Die Head Blow Moulding Machine. GEFRAN CONTROL SYSTEM -PID Temperature Control System (With High/Low Alarm) -Motor PID Feedback Control Function -300 Points Parison Control -PLC Ladder Program Edlitor -Presscription Record Memory Accumulator Die Head Blow Moulding Machine AUTO-DEFLASHING UNIT This Unit Can Be Excuted Top/Bottom/Handle Deflashing Function By Hydraulic And Pneumatic. And Then Used With Suction Device To Take Out And Turn Over The Production.

Full Range of Film Processing Machinery at K 2022 | JINMING

PRM was pleased to have a short interview with Simeon Wang, Vice President of Jinming Machinery, at K 2022. By interviewing with Mr. Wang, we have obtained the information about MDOPE solution, which was launched in recent years, to enable the stretch of the film manufactured from its machine. Moreover, Mr. Wang has expressed how Jinming solved the clients’ problems by its automatic technology during the pandemic. In the meanwhile, he also shared his observation of sustainability and expectation of the market in the post-pandemic era.

GMA 30th Anniversary - Extrusion Dies Empowered by Innovation | GMA

GMA Machinery Enterprise Co., Ltd. has manufactured extrusion-die and has focused on the technology of extrusion & coating dies for many years. In 2019, GMA welcomed its 30th year anniversary with abundant experience in this industry. GMA supports your business & creates wonderful life by the following values: - Excellent Product Performance - Quality Policy - Highly Precision Quality & Products 【Features】 - Complete Production Management - Precision Machine - In-house Chrome-plating Facility 【Industry Involved】 - Industrial Construction Material - Photoelectric Energy Saving - Aviation & Automotive - 3C Digital - Medicine Hygiene - Food Table Wares

Plastic Welding Machine at K 2022 | TAI YEN

By interviewing Mr. Tony, from Tai-Yen Industrial Co., at K 2022, we have a quick understanding or their solution and product series, such as High Frequency Plastic Welding Machine and Ultrasonic Plastic Welding Machine.

Continuous Thermoforming Machine SL-1220A + SL-520 for Lid Production | CHULIING

【MACHINERY IN THE VIDEO】

Bag Making Machines for Multiple Applications | WORLD STEEL

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, World Steel is dedicated to making technological innovations and manufacturing packaging machines. The company has one of the best engineering crews in the industry to provide total solutions which include design, customization, and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self-adhesive bags, handle bags, sandwich bags, or more, then World Steel is one of the best choices for you.

ABA Blown Film Machine (JC-ABA) | PLASCO

PLASCO's JC-ABA Series of 3-layer co-extrusion blown film lines are the ultimate economic and environmental solutions for multi-layer blown film production. 【Machine Spec】 Applicable Material: LDPE / LLDPE / MDPE / HDPE Screw Diameter (mm): "45/55", "50/55", "55/75" Film Layflat Width (mm): 800 / 1000 / 1200 Film Thickness (mm): 0.015-0.10 Extrusion Capacity (kg/hr): 100 / 160 / 250 【Application】 Express Bag Plant Bag Shopping Bag T-shirt Bag Laundry Bag Garbage Bag 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Quick Mold Change System|Sistema cambio rápido moldes|быстрый mold изменение системы|SANDSUN

Learn more about the Quick Mold Change Systems : https://bit.ly/37ST04V Sistema de cambio rápido de moldes, быстрый mold изменение системы, السريع تغيير النظام العفن produced by SANDSUN Introduction of our Quick Mold Change System : It is an era for making high frequency mold changes with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System. Sandsun safety function of Quick Mold Change System : ✔️Each hydraulic circuit has the function of checking and avoiding oil leaking. ✔️This system can add pressure automatically when the pressure reduction. ✔️Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine. ✔️It adopts the intersecting direction to clamp the mold. ✔️There are several functions to avoid operation error. Explanation of video content : Mold Change less than 2 minutes on 1300T injection molding machine 0:00 Quick mold change less than 2 minutes on injection machine 0:19 Pre-load the mold on the cart 0:23 Mold move out 0:36 Mold arrive in the position, and the cart start to switch position 0:49 Mold cart arrive in position 0:55 Injection machine adjust the stroke for mold automatically 1:04 Mold move in 1:21 Hook back to original point, door close automatically 1:28 Mold close, clamps lock the mold automatically 1:39 Protection rods rise, cart start to move 1:49 Cart back to mold hanging area, finish mold change

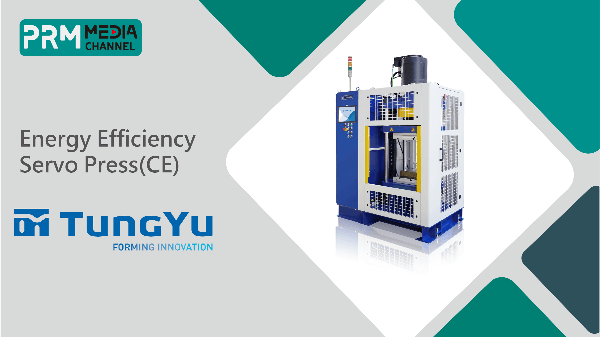

TungYu Energy Efficiency Servo Press(CE) | Tung Yu

⚫Servo motor drive:Servo press use servo motor as the power source, with transmission mechanism and pressure sensing element to provide the required power for the press, and link the guide screw straight joint press head (or center base) to directly provide the required load for the workpiece. ⚫Planetary roller screw:Planetary screw uses a roller instead of a ball between the screw and the nut to greatly improve the rigidity and increase the contact area. The roller rotates around the screw in the same way as the earth orbits the sun, and the loading capacity is three times that of a ball screw, which improves stability and thus extends the life of the screw. ⚫Independent heating platen temperature control system:Provide preheating function before the mold waiting for hot press molding, shorten the hot press molding time and improve the production efficiency. ⚫Energy saving and environment cleaning:The power consumption rate of the servo motor is more economical than traditional motor with pump design.Without hydraulic system there is no oil leakage and low maintenance.It is suitable for working environments with low pollutions, such as electronics industry, biotechnology industry, etc. ⚫Precise movement:Control parameters can be input from HMI, and action commands can be issued to driver through PLC and implement servo motor actuation to achieve high-precision control on working force, speed or position performance. The servo motor is directly connected to the lead screw head (or moveable traverse) through the transmission to have direct required load.The features are to precisely provide key parameters of working force, speed and position in production. ⚫Complete process setting function:It is convenient for the user to set up process parameters and save portable files as backup. ⚫Convenient data tracking and statistical result output:The data and graphs of each cycle could be presented as batch statistical information for tracking by operator easily. ⚫Real-time monitoring of press status:Display of cycle graph and monitoring of press status, sensors and statistics. Real-time production information such as quantity and yield rate to improve the control efficiency and accuracy.

PVC Medical Tube Extrusion Machine Line (High speed type+Dust proof) | Everplast

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry. *Contact Info: Web: https://www.everplast.com.tw/ Facebook: https://reurl.cc/r1LZb YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg 1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/ 2.https://www.everplast.com.tw/product/machine-line/ 3.https://reurl.cc/QeMrp0 Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Extrusion die and peripherals manufacturer | GMA

Founded in 1989, the GMA Machinery Enterprise Co., Ltd. (GMA), an R&D team composed of senior design engineers and technicians with decade’s strong experience in sheet and film extrusion equipment and auxiliary parts, has been devoted to providing custom products based on customer requirements. With 30 years of continuous efforts, it is the one of the best manufacturer in the world. Based on comprehensive processing equipment, GMA is able to exercise strict quality control throughout the whole in-house process from product design, manufacturing, assembling and inspection which, in turn, has earned customers’ continuous recognition and praise.