Company Profile of Parker Plastic Machinery | PARKER

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Quick Mold Change System|Sistema cambio rápido moldes|быстрый mold изменение системы|SANDSUN

Learn more about the Quick Mold Change Systems : https://bit.ly/37ST04V Sistema de cambio rápido de moldes, быстрый mold изменение системы, السريع تغيير النظام العفن produced by SANDSUN Introduction of our Quick Mold Change System : It is an era for making high frequency mold changes with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System. Sandsun safety function of Quick Mold Change System : ✔️Each hydraulic circuit has the function of checking and avoiding oil leaking. ✔️This system can add pressure automatically when the pressure reduction. ✔️Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine. ✔️It adopts the intersecting direction to clamp the mold. ✔️There are several functions to avoid operation error. Explanation of video content : Mold Change less than 2 minutes on 1300T injection molding machine 0:00 Quick mold change less than 2 minutes on injection machine 0:19 Pre-load the mold on the cart 0:23 Mold move out 0:36 Mold arrive in the position, and the cart start to switch position 0:49 Mold cart arrive in position 0:55 Injection machine adjust the stroke for mold automatically 1:04 Mold move in 1:21 Hook back to original point, door close automatically 1:28 Mold close, clamps lock the mold automatically 1:39 Protection rods rise, cart start to move 1:49 Cart back to mold hanging area, finish mold change

5 Gallon PET Preform Turnkey Solution | KING'S SOLUTION

5 Gallon PET Preform Turnkey Solution | KING'S SOLUTION -------------------------------- MANUFACTURER: KING'S SOLUTION CORPORATION MODEL: KPET3200 ------------------------------- SPECIFICATIONS: 700g preform x 8 cavities 90 secs Cycle time 7,200 pcs/day

Vacuum Molding Machine | LIN CHENG

Vacuum Molding Machine - Oil Seal Vacuum Molding Machine- LIN CHENG Specializes in Vacuum Molding Machine, Lin Cheng Technologies Co., Ltd. was established in 1978 and has a strong professional team to manufacture Vacuum Molding Machine. A series of services we can provide ranges from the purchase of machines to the design and development of molds. Our Vacuum Molding Machine products are used for electronic components, car parts, oil rings, and so on. In 1997, we were granted the ISO 9002 quality certification.

Accumulator Blow Moulding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. Detail Specifications : The Abl Series Blow Moulding Machines Are Particularly For Producing The Jerry Can/Drum Tank/Large Article Produtions.It Can Be Combined With Some Accessory Equipments To Increase The Efficiency And Expand The Functions, Such As: After Cooling Unit/Auto Deflashing Unit. The Die Head Can Stock The Melting Resin And Purge The Material For Blowing Formed It Designed With Two Heart Flow Chnnels.Can Make Welding Line-Free To Increase The Strength Of Production. The Tie Bar-Less Clamping Unit Is Consist Of Stiffness Structure Frame And Guiding Devices.Make Sure Deflection-Free Advantage. Also Devise With Precision Rack GgearsO of Bboth Side.Make Synchronize Moving Of Plates. The Blowpin Unit Is Designed For Production Calibrating. That Will Be Suited For Different Demand Of Customer. Accumulator Die Head Blow Moulding Machine. GEFRAN CONTROL SYSTEM -PID Temperature Control System (With High/Low Alarm) -Motor PID Feedback Control Function -300 Points Parison Control -PLC Ladder Program Edlitor -Presscription Record Memory Accumulator Die Head Blow Moulding Machine AUTO-DEFLASHING UNIT This Unit Can Be Excuted Top/Bottom/Handle Deflashing Function By Hydraulic And Pneumatic. And Then Used With Suction Device To Take Out And Turn Over The Production.

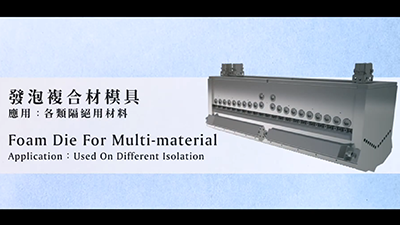

Extrusion Die - Foam Die For Multi-materials | GMA

Extrusion Die - Foam Die For Multi-materials | GMA Offers a variety of extrusion die. GMA MACHINERY ENTERPRISE was established in 1989. GMA specialized in extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer. To meet extruding processor requirements, in 1990, GMA became involved in T-die design and manufacturing for sheet, film and coating film production. Over the years, we have invited several high molecular masters and doctors to research and develop various T-die manufacturing technology. GMA extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer, GMA products have been sold to worldwide markets, such as: the U.K., Japan, the U.S.A., Italy, Brazil, Argentina and China, etc. We can offer best quality which can reach American and Japan level.

Digital Transformation for Packaging Industry | Taiwan Packaging Association

In this video, we interview the new Chairman of Taiwan Packaging Association, Mr. Benker Liao. Throughout this video Mr. Liao introduces the importance of participation in the international exhibitions for the Packaging Industry and how it was affected during the pandemic. The new Chairman has encouraged the players of Taiwan Packaging Industry to make a change in mindset, organizational and business transformation for Online Marketing.

Surface Modeling 3D Printing | time lapse | Everplast

Surface Modeling 3D Printing | time lapse | Everplast ①The EM3-3505-CMT is an industrial pellet 3D printer manufactured by Everplast from Taiwan. ②This 3D printer is able to utilize compound cement raw material to build products or samples. ③The standard formulation database and material bank are provided along with the 3D printer.

Plastic Bag Folding, Sealing & Cutting Combo Machine

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, they are dedicated to making technological innovations and manufacturing packaging machines. World Steel on PRM: https://www.prm-taiwan.com/shorturl/Qrm7p5Qg

JAW FENG MACHINERY | PRM Media Channel Interviews at TAIPEI PACK 2020

PRM Media Channel glad to share our recent interview with JAW FENG MACHINERY at TAIPEI PACK 2020. Ms. Mary Kuo shared deep insight into the packaging industry not only for the Taiwanese market but also the global market. She mentioned the effects of the pandemic on the vacuum packaging machinery industry specifically. She also shared with us how the companies are affected based on their sizes. TAIPEI PACK is a prestigious exhibition for JAW FENG MACHINERY, the company attends the exhibition every year at the same booth location and showcases many different vacuum packaging machinery customized based on the various needs of the customers. We suggest that it is worthy to take a look at the interview video. Your opinions and questions are most welcomed in the comment section. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

Plastic Bag Making Machine | WorldSteel

Suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips. Using a vertical up and down heat sealing system and supersonic sealing line device. Provide extra parts for improved production accuracy and quality, including EPC edge sensor, servo motor to drive the machinery and an automatic conveyor to get your finished products to the packing section as soon as possible. Suitable for already perforated and/or folded films. 【Company Introduction】 World Steel Machinery Company is dedicated to making technological innovations and manufacturing packaging machines.They have the best engineering crew in the industry to provide total solutions which include design, customization and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self adhesive bags, handle bags, sandwich bags or more, then World Steel is the best choice for you.

PVC Medical Tube Extrusion Machine Line (High speed type+Dust proof) | Everplast

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry. *Contact Info: Web: https://www.everplast.com.tw/ Facebook: https://reurl.cc/r1LZb YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg 1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/ 2.https://www.everplast.com.tw/product/machine-line/ 3.https://reurl.cc/QeMrp0 Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

PA/PET Monofilament Extrusion Line (JC-MNN) | PLASCO

PLASCO's JC-MNN series of extrusion lines utilize a dual-stage drawing/single-stage heating process to produce high quality PA6, PA66, PET or PP monofilament extrusion line. 【Product Spec】 Applicable Materials: PA/PET Screw Diameter (mm): 50 / 55 / 65 / 80 Filament Diameter (mm): 0.12-1.00 / 0.12-3.50 / 0.50-3.50 Extrusion Capacity (kg/hr): 35 / 50 / 75 / 120 【Application】 Rope Toothbrush Longline monofilament Fishing line Tennis strings Fishing net 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO

MACHINERY IN THE VIDEO: CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO - 8 colors central impression flexo printing machine - High precision stainless-steel impression drum imported from Italy - Automatic water temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

Medical spiral tube extrusion machine line (double output ) | Everplast

Medical spiral tube extrusion machine line (double output ) The medical tube, made by food-grade materials, with the advantage of high transparency, good elasticity, good fluidity and corrosion resistance, suitable for medical, pharmaceutical and food production of gas and liquid delivery pipes, etc. -Contact Info: Twitter: / everplast Facebook: https://reurl.cc/r1LZb Web: https://www.everplast.com.tw/ Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

PP Strapping Band Extrusion Line (JC-SPP) | PLASCO

PLASCO's JC-SPP Series of extrusion lines are designed to produce PP strapping bands, which are commonly used for light- and medium-duty applications, such as for securing newspapers and magazines, carton boxes, and pallet freight shipments. 【Machine Spec】 Applicable Material: PP Screw Diameter (mm): 90 / 100 / 120 Strap Width (mm): 5-19 / 12-19 Extrusion Capacity (kg/hr): 180 / 250 / 380 Straps Produced: 4-2 / 8-4 / 8-6 【Application】 Newspaper strap Carton box strap 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

TungYu Energy Efficiency Servo Press(CE) | Tung Yu

⚫Servo motor drive:Servo press use servo motor as the power source, with transmission mechanism and pressure sensing element to provide the required power for the press, and link the guide screw straight joint press head (or center base) to directly provide the required load for the workpiece. ⚫Planetary roller screw:Planetary screw uses a roller instead of a ball between the screw and the nut to greatly improve the rigidity and increase the contact area. The roller rotates around the screw in the same way as the earth orbits the sun, and the loading capacity is three times that of a ball screw, which improves stability and thus extends the life of the screw. ⚫Independent heating platen temperature control system:Provide preheating function before the mold waiting for hot press molding, shorten the hot press molding time and improve the production efficiency. ⚫Energy saving and environment cleaning:The power consumption rate of the servo motor is more economical than traditional motor with pump design.Without hydraulic system there is no oil leakage and low maintenance.It is suitable for working environments with low pollutions, such as electronics industry, biotechnology industry, etc. ⚫Precise movement:Control parameters can be input from HMI, and action commands can be issued to driver through PLC and implement servo motor actuation to achieve high-precision control on working force, speed or position performance. The servo motor is directly connected to the lead screw head (or moveable traverse) through the transmission to have direct required load.The features are to precisely provide key parameters of working force, speed and position in production. ⚫Complete process setting function:It is convenient for the user to set up process parameters and save portable files as backup. ⚫Convenient data tracking and statistical result output:The data and graphs of each cycle could be presented as batch statistical information for tracking by operator easily. ⚫Real-time monitoring of press status:Display of cycle graph and monitoring of press status, sensors and statistics. Real-time production information such as quantity and yield rate to improve the control efficiency and accuracy.

Film Extrusion Equipment at K 2022 | GMA

It was a great honor for PRM to interview the General Manager — Howard Chao from GMA Machinery. He shared his insight about how the Russo-Ukrainian War affected Europe Energy Policy and the European market. He's also looking forward to having cooperation opportunities with new partners. For more information, check the video!

Double Injection Mold Expert & Solution | YOMURA

Yomura Technologies Inc. was founded in 1989. With over 30 years of experience, we have been selected as OEM by multiple world-class brands. Moreover, Yomura has the tooling expertise to fabricate complex, high-end molds and the production capacity to manufacture large volumes of precision parts for just about any industry, such as 3C consumer goods, medical, automotive, aerospace products, military & industrial gear and more. 【Service Line】 Single Injection Mold Double Injection Mold Over Injection Mold Insert Injection Mold In Mold Decoration Liquid Injection Molding Metal Injection Micro Molding EMI Shielding Contract Assembly Optical Lens & LED Blow Molding Contract Mold Manufacture Silicone & Rubber Products 【Engineering】 Design and Development Partner Rapid Prototyping Tooling Soft Tooling Process Optimization

Flexo Printing Machine Stack Type - Double Side 2+2 | ROTOFLEXO

ROTOFLEXO Stack Type Flexo Printing Machine - 250 M MIN - Double Side 2+2 - High precision cylinders, anilox rollers, and guiding rollers - Automatic temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

YF Super Sealer | PRM Media Channel Interviews at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. During the exhibition, PRM Media Channel conducted an interview with Mr. Kevin Chang from YF Super Sealer (Y-Fang Group). We have talked about the current situation of the packaging industry during the pandemic, the new methods of the company to sustain efficient customer care. Moreover, Mr. Chang introduced the showcasing machine, which is designed especially for the take out food industry and ready food industry. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for similar videos!~