Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Gravimetric Technology at K 2022 | MAGUIRE

Founded in 1977, Maguire Products manufactures gravimetric blenders and feeders, volumetric feeders, ULTRA low energy dryers, conveying systems, extrusion control systems, loss in weight extrusion control, and related auxiliaries for Plastic & Rubber industry. It was a great honor for PRM-TAIWAN to invite Frank Kavanagh — Vice President Global Sales and Tony Tsai — Sales Manager (Taiwan) from Maguire. The conversation was mainly about the biggest challenge during the pandemic and how to integrate product innovation into application of Circular Economy, Digitalization, Climate Protection, which was the 3 main topics of K 2022. In the end, Mr. Kavanagh also talked about their main goal of the attendance. For more information, check the video!

Thermoforming Machine | CHULIING

Thermoforming Machine-Continuous Thermoforming Machine Chuliing Machinery Co., Ltd was established in 1985 and is now an expert in manufacturing Thermoforming Machine. Our products are sold worldwide and we are well-known die cutting machine manufacturer. Chuliing Machinery has a commitment to technological innovation so as to benefit his customers and agents from all aspects. We also dedicate ourselves to develop automatic equipment and to train our employees to further enhance our Thermoforming Machine product quality.

LUYANG | PRM Media Channel Interviews at TAIPEI PACK 2020

Welcome to take a look at our recent interview with LUYANG TECHNOLOGY COOPERATION COMPANY at TAIPEI PACK 2020. Ress from PRM Media Channel interviewed Ms. Mavis Ou, and gathered info about LUYANG's latest technology motors, gearboxes, and drivers. As Ms. Ou stated,unlikely many companies focus only one product line, LUYANG manufacture motors, gearboxes, and drivers all together to provide a complete solution to its customers. This is crucial especially after Covid-19 brings some difficulties in terms of logistics and communication. LUYANG also attends TAIPEI PACK for many years, thus Ms. Ou has a broad insight into and comparison of the previous and current versions of the exhibition. During the interview, we had also a chance to hear her expressions about the market. Thank you for your opinions and questions in advance in the comment section. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

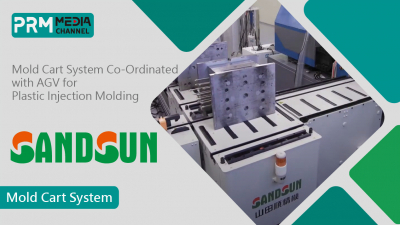

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

Film Extrusion Equipment at K 2022 | GMA

It was a great honor for PRM to interview the General Manager — Howard Chao from GMA Machinery. He shared his insight about how the Russo-Ukrainian War affected Europe Energy Policy and the European market. He's also looking forward to having cooperation opportunities with new partners. For more information, check the video!

5G PET Preform Turnkey | KING'S SOLUTION

5G PET Preform Turnkey - 5 Gallon PET Preform Injection Molding Machines & Whole Plant Turn-Key Solution-pet-King's Machinery. FEATURES Select from 2, 4 or 8 cavities mold specifications. Single mold, 4 cavities design. The 2 stage material feed system raises the repeatability rate, lowers the cycle time, and boosts performance. When combined with a secondary cooling system, performance can be doubled. Temperature control via TSR raises temperature accuracy and, working with the accumulator, increases injection speed. Unique economical design is twice as energy efficient as comparable commercial units. we offer a complete set of 5 gallon PET bottle manufacturing equipment: raw material dehumidification and drying system; fixed-volume color additive; quickly stabilizing PET bottle preform molding machine; 4 cavity, hot runner mold; rapid cooling robot; and bottle blowing machine. From raw material to finished product stages, this all-inclusive system promotes high productivity, low cost, and superior quality-the bottle blowing defect rate is kept to a minuscule 0.5%. When water is shortage and lack of quality sanitary sewer, therefore, water container or bottle is convenience to filling in clean water and to carry with to the public. Moreover, bottle is not only for water-use but also oil-use even other liquid-use. King's gallon-size pre-form is one of the best choices in worldwide. Not only does save 20% of shipping cost but also decrease defect of blowing rate down to less 0.5%. And the most critical point is that any color is so clear by King's latest technology and 20 years PET knowledge.

CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO

MACHINERY IN THE VIDEO: CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO - 8 colors central impression flexo printing machine - High precision stainless-steel impression drum imported from Italy - Automatic water temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

Company Profile of Parker Plastic Machinery | PARKER

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

Surface Modeling 3D Printing | time lapse | Everplast

Surface Modeling 3D Printing | time lapse | Everplast ①The EM3-3505-CMT is an industrial pellet 3D printer manufactured by Everplast from Taiwan. ②This 3D printer is able to utilize compound cement raw material to build products or samples. ③The standard formulation database and material bank are provided along with the 3D printer.

Plastic Welding Machine at K 2022 | TAI YEN

By interviewing Mr. Tony, from Tai-Yen Industrial Co., at K 2022, we have a quick understanding or their solution and product series, such as High Frequency Plastic Welding Machine and Ultrasonic Plastic Welding Machine.

Haitian Shows Machines for All-electric and Thin-wall Injection Molding Trends (Chinese Interview)

HAITIAN INTERNATIONAL HOLDINGS LIMITED Haitian International Holdings Limited develops and produces the international machine concept of the 21st century. Our sophisticated product portfolio of injection molding machine construction covers the entire spectrum of the plastics processing industry and meets the most diverse customer demands for the manufacture of mass and high-precision plastic products.

JCtimes Debuts 2.5D Algorithm to Revolutionize Multi-layer Co-extrusion (Chinese Interview)

JCtimes Group dreams of what customers dream and pursues a globalized brand strategy. Owning three brands Jingcheng, JCTIMES, and Goodee, JCtimes Group has dedicated to the production, application, and R&D of extrusion dies and auxiliary equipment, and achieved over 70% domestic market share in China’s high-end market. JCtimes, a world-leading brand in the global flat-dies extrusion industry, has focused on the development of new materials, technology, and technique for more than 20 years. Key technical advantages in flow channel simulation system, five-axis processing, and precise grinder provide integrated solutions in sheet, foil, and film material fields. The products have been widely applied in electronics, automobiles, building materials, optics, new energy (solar energy, hybrid vehicles, lithium battery), health care, food packing, and other life aspects.

Jwell's high-speed and high-efficient blow molding technology accelerates packaging development (Chinese & English Interview)

SUZHOU JWELL PLASTIC MACHINERY CO., LTD. Suzhou Jwell blow-molding machinery is another important strategic development center of Jiangsu Jwell plastic Machinery Co., LTD, located in Suzhou Taicang FOSHAN BEKWELL INTELLIGENT EQUIPMENT CO.,LTD. Foshan Bekwell Intelligent Equipment Co.,Ltd. is another important development strategy center of Shanghai JWELL Machinery Co.,Ltd. Locating at Lunjiao sireet Shunde district Foshan City,a high-tech manufacturer specializing in research and development of plastic extrusion equipment. The factory area is of 30 acres, more than 100 staff and 20 technical and management employees; We have a high qualified R&D and experienced mechanical and electri-cal engineer team as well as advanced processing foundation and normative assembly shop. We supply more than 200 sets lines annually. Our enterprise spirit is "Attentive, Enduring, Quickly and Orderly", keeping on exploring of new extrusion field. Mostly welcome to new and old customers to visit us for investigation, guidance and cooperation. We are happy to offer powerful support!

Leading Global PEEK Company Victrex Reinforces The Presence and Capacity for China and Asia

Victrex is an innovative world leader in high-performance polymer solutions, focused on the strategic markets of automotive, aerospace, energy, manufacturing & engineering, electronics and medical. Every day, millions of people use products and applications, which contain our materials from smartphones, aeroplanes and cars to oil and gas operations and medical devices. With over 40 years experience, we develop world leading solutions in PEEK- and PAEK-based polymers and selected semi-finished and finished parts which shape future performance for our customers and our markets.

Blown Film and Recycling Machines - POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, Daniel from PRM will be carrying the interview with the Chief Marketing Officer Mr. David Lo. During the interview, Mr. Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

HSIN LONG Blown Film Die Heads | CHINAPLAS 2021

PRM Media Channel is very glad to announce the great cooperation with CPRJ, the official media group of CHINAPLAS. For this great opportunity, we bring you one of our special actors in the Blown Film Die Head Industry to share with us important facts & insights into the industry, and how their expertise reflects an outstanding performance on customer service, manufacturing process, and quality field. With half a century of rich experience in manufacturing, HSIN LONG is mainly specialized in producing Blown Film Dies and related components. These components can be applied in Packaging Films, Barrier Films for food packaging, Technical Films for high-tech applications, Sealing Films, Agricultural Films, Medical Films, Shrink and Stretch Films, TPU Films, Biodegradable Plastic Bags / Green Plastic Bags, and many more. In this video, our PRM Marketing Specialist Billy will be carrying the interview with the Special Assistant to the GM, Sandy from HSIN LONG Thread Rolling Co.

Three Systems for Thermoforming Machines - CHUDONG | CHINAPLAS 2021

PRM Media Channel continues with this great cooperation we began with CPRJ, the official media group of CHINAPLAS, providing insights about Taiwanese experts in the Plastic and Rubber Industry. In this specific case, we had the great opportunity to interview one of our special actors in the Thermoforming Machinery Industry who will give us some great insights of the related industry. CHUDONG Machinery is a professional manufacturer with more than 35 years of experience in manufacturing & developing thermoforming technology and services in forming, cutting, and stacking in one place. The core for growth and success according to CHUDONG is having a strong R&D that can create specific systems to different markets. In this video, our PRM Director Alice will be carrying this interview with President Chester Chen & Vice-President Sophie Lu from CHUDONG Machinery Company. In the following President Chester Chen & V.P. Sophie Lu will be covering more about the three systems for air pressure thermoforming machines for the European, Japanese, and Asian markets: 1. Three Systems for Thermoforming Machines 2. Key Factors for Product Development 3. Differences between these Three Thermoforming Machine Systems 4. 2021 Innovations and Developments 5. CHINAPLAS Exhibition 2021

Leading European PA Supplier DOMO Accelerates Strategic Development in Asia Pacific (English & Chinese Interview)

Domo Chemicals is a leading producer of high-quality engineering materials and versatile plastics for industrial and consumer applications in a diverse range of markets, including the automotive, food, medical, pharmaceutical, chemicals and electronics industries. The company offers a complete portfolio of integrated nylon 6 and Nylon 66 products, including intermediates, resins, engineering plastics and packaging filmand distribution of petrochemical products. Headquartered in Germany, the family-owned company leverages advanced technology and consumer insights to deliver sustainable & innovative solutions.

Expanding Polymer Horizons: OQ Committed to Innovation and Sustainability of Polyolefin (Chinese Interview)

OQ is a global integrated energy company with roots in Oman. It emerged in late 2019 upon the successful integration of nine legacy companies, united to form a stronger, more efficient, and consolidated entity. We operate in 17 countries and cover the entire value chain in the hydrocarbon sector from exploration and production, to marketing and distribution of end-user products. Our fuels and chemicals are sold in over 60 countries worldwide. We also partner with local and international companies in the hydrocarbon sector to increase value for the shareholders and reap greater benefits for the communities.

Donghua Machinery's High-precision All-electric Machine for Medical Applications Debuts, Chemical Foaming Promotes Automotive Lightweighting (Chinese Interview)

Donghua Machinery Ltd. is a subsidiary of Cosmos Machinery Ltd., the Hong Kong joint venture enterprise for manufacturing full-automatic computer-controlled injection moulding machines and auxiliary equipment. Donghua was founded in 1986, Donghua can provide a whole set of injection moulding machine and its auxiliary equipment to customers on turnkey basis, with 43g to 300,000g injection volume, 25T to 4,000T clamping force, totally in over 90 models with various design specifications. The yearly output capacity is over 5,000 machines.