All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com [email protected]

2024 CHINAPLAS Interview | HCI

We are here with Terence from HCI Converting Equipment at the CHINAPLAS. HCI is a specialist in the Converting Equipment and Slitter Rewinder machinery, able to provide from a single machine to whole plant equipment. We heard very valuable information from Terence, thank you so much!

2024 Expo Plasticos Guadalajara | HAO YU PRECISION MACHINERY INDUSTRY CO., LTD.

Join us as we interview Hao Yu Precision Machinery Industry Co., Ltd. at ExpoPlasticos 2024! We shine a spotlight on Hao Yu’s expertise in manufacturing PP/HDPE woven bag-making machines. With 26 years of local experience in Mexico, Hao Yu’s unique advantage lies in its direct communication with customers, ensuring tailored solutions to meet their needs. Their commitment to sustainability, combined with a strong willingness to engage directly with local buyers, enables them to deliver highly customized solutions that meet diverse needs.

TaipeiPLAS 2022 Live | PRM x KAOLU x PIDC

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 9/30(Fri.) 15:00 (GMT+8) 【KaoLu Enterprise】 Kao Lu Enterprises Co. Ltd., established in 1980, has been dedicated to manufacturing and supplying premium quality pneumatic components such as valves, cylinders, and ancillary accessories. 【Plastics Industry Development Center | PIDC】 What's the key role that PIDC plays in Taiwan society and how they provide services to plastics manufacturers. By interviewing General Manager of Dr. Hsiao, he would share the insight of SDGs, 2050 Net Zero programme, and also provide advice to Taiwanese enterprises.

Exploring the Future of Packaging Machinery with Thomas Dohse | Shanghai swop Interview

In this exclusive interview at Shanghai swop, we sit down with Thomas Dohse, a key figure from interpack, to dive deep into the future of packaging machinery and the emerging trends shaping the industry. Discover the fascinating highlights of the swop exhibition, including innovative technologies and unique insights into the latest advancements. Thomas also shares his perspective on the resurgence of globalization, which has taken a new form through fragmented and decentralized transactions, creating fresh opportunities for businesses worldwide. Finally, Thomas gives us a sneak peek into the 2026 interpack, unveiling its central themes and what we can look forward to in this global event. Don’t miss this insightful discussion that combines cutting-edge trends with a vision for the future of packaging!

KAIMEI | PE Extruding Blow Molding Machine for Product Maximum to 1,500L - PBI-1305X-

Kai Mei Plastic Machinery Co., Ltd. established in 1977, is a highly reputed manufacturer of blow molding machines. Different types of machines are designed to produce containers of various raw materials such as PE, PVC, PP, PETG, PU, etc. Kai Mei can produce 5-ml containers of PBA Series Machines to 1,500-liter containers of PBI-X Series Machines. These are fully recognized by customers around the world.

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

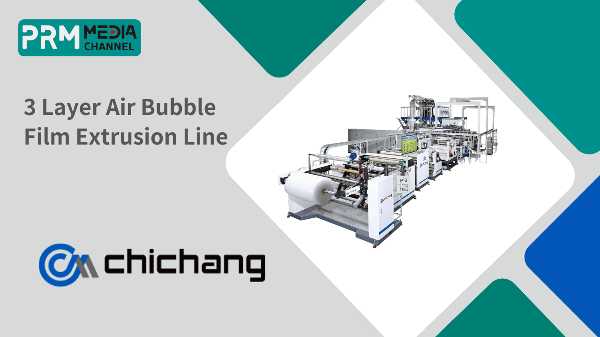

3 Layer Air Bubble Film Extrusion Line | CHI CHANG-

MACHINERY IN THE VIDEO: 3 Layer Air Bubble Film Extrusion Line from CHI CHANG MACHINERY APPLICATIONS: The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope.

PRM Packaging Theme Pavilion | PRM What to Say EP7

Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event “PRM Theme Pavilion”, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry.

5 Benefits of Flexo Printing Machines | PRM What to Say EP11

There are several types of printing techniques available for the plastic packaging industry. Such as flexo printing, offset printing, and screen printing. Although flexo printing is not a new technology, it is the most common method for packaging printing. Then let’s take a glimpse of the video to understand what flexo printing is and what makes it most preferable. Flexographic printing is a technique that uses a flexible printing plate. The plates are wrapped around cylinders on a web press. The inked plates have a raised image and rotate at high speeds to transfer the ink through small holes from the anilox roll to the substrate, which is the printed surface. So, what makes flexo printing the most common method? You will find 5 reasons why in the video.

rPET Bottle for Household Packaging Solution | ChumPower

Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries. 【Product Appliance】 Beverages Water Edible Oil Daily-used Cosmetics 【Product Range】 One Stage Injection Blowing Machine Injection and Bottle Molding Manufacturing Stretch Blow Molding Machinery Sales / Turnkey Solution TS Series Models for Lower Production Output (Suggest to new market players) Linear PET Blow Molding Machine (Suggest to buyers who is looking for higher output) 【SS10-rPET Single-stage PET Bottle Blowing Machine】 Hybrid hydraulic system with an optimized clamping mechanism to ensure Energy Efficiency Barrier screw with venting capability can effectively lower the energy required for drying Adopt 4 station design Non-contact feature Reach the trending topics of ESG, Carbon Neutrality, and Net-Zero Emission

All-Servo Drive T Shirt Bag On Roll Bag Making Machine ft. Swing Type Feeding System | PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

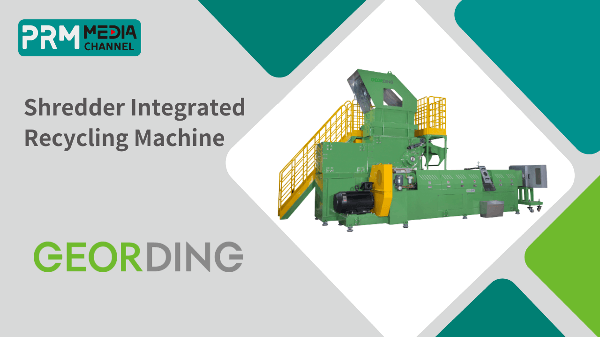

Plastic Washing Machine | GEORDING

Plastic Washing Machine - Plastic Film Crushing Washing and 3IN1 Pelletizing Line - Waste Plastic Crushing & Washing Line 1000kg - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of Plastic Washing Machine. The main businesses include: Plastic Washing Machine and planning of entire plant’s equipment. While the demand for output and quality in Plastic Washing Machine worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Plastic Washing Machine products and services to higher standards.

Label Converting and Finishing System | YICHEEN

Machinery in the Video: Label Converting and Finishing System from YICHEEN Features: * Running operated by full rotary die cut method or intermittent die cut method. * Die is easy in change, save a lot of time in die mold adjustment. * Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession. * Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control. * Sensor detector and alert for broken material to reduce material lost. * Optional module for satisfying customized demands. * Optional Mechanism: EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet * Application: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material, and so on.

WEI MENG | WMD Onion Bag Making Machine

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets. This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system. If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business. Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making. This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.

Exclusive Interview: Jawhari Kamil on the 20th Saudi PPPP and Vision 2030

Join host Jason as he sits down with Jawhari Kamil, chief organizer of the 20th Riyadh Expo, for an insider’s look at this landmark event. In just a few minutes you’ll learn: What makes the 20th Saudi PPPP and how it reflects Saudi Arabia’s rapid industrial momentum Kingdom Vision 2030 in action—why national transformation goals are shaping every corner of the show Sustainability in focus: from low-carbon solutions to green partnerships that matter A surprise reveal: Jawhari hints at a major collaboration with a world-famous exhibition coming in 2026—watch to the end to find out which one! Whether you work in plastics, packaging, or any sector eyeing the Middle East, this interview delivers fresh insights you won’t want to miss.

Plastic Bags on Roll Making Machine Series | CHAO WEI

Introducing a full range of Plastic Bags On Roll Making Machine Series from CHAO WEI, which is a pioneer plastic bag making machine manufacturer in Taiwan with more than 35 years of experience in this field. 【SPECIALTIES OF CHAO WEI】 Bag on Roll Machines T-Shirt Bag Making Machine Side Sealing Machines Bottom Sealing Machines Whole Plant Equipment 【ABOUT CHAO WEI】 CHAO WEI Plastic Machinery Co., Ltd. is an advanced manufacturer of plastic bag making machines with more than 35 years of experience with ISO 9001 & CE certificate in Taiwan. CHAO WEI’s main goal is to enhance the value of machines and to create new performance capabilities that will meet the customers’ production efficiency and profitability.

Shredder Integrated Recycling Machine | GEOR-DING-

Shredder Integrated recycling machine Features: -Can handle large heavy materials or thin-film materials 0:50 -Automatic backfllush screen changer,Reduce the screen changing labor cost 1:03 -Side Feeding Twin Screw design

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

Recently despite many exhibitions that have been canceled or postponed, CHINAPLAS 2021 successfully made the event to be held on time, April 13th to 16th, 2021. In this manner, PRM Media Channel has conducted an online interview with Ms. Ada Leung, the General Manager of Adsale Exhibition Services Ltd., the organizer of CHINAPLAS. Ms. Ada Leung sincerely replied to our questions about this special event at a special time due to the pandemic. She also shared very useful information about the forthcoming CHINAPLAS 2021 including the focus of the exhibition, online activities for the visitors who cannot attend the exhibition, future plan of CHINAPLAS through digitalization and hybrid exhibition model. Let's take a look at the interview video to learn more, and let us know your opinions and questions.

【Turnkey】Biodegradable / Compostable Straw Making & Packing Machine | JUMBO STEEL

Jumbo Steel has more than 30 years of experience in manufacturing straw making machines and straw packing machines. Moreover, Jumbo Steel is providing turnkey solutions for your business according to your needs. 【Product Lines】

Industry 4.0 Smart Factory for Injection Molding - sFactory 4.0 | SHINI

【VIDEO FOCUS】: SHINI Industry 4.0 Smart Factory for Injection Molding which is called "sFactory 4.0" 【ABOUT SHINI】 Derived from Taipei, Taiwan, Shini group has gone through an extraordinary journey for more than 40 years. To date, Shini group has established six production bases and one corporate technology center globally. Specialized in manufacturing plastic auxiliary equipment, Shini products consist of eight series, including drying & dehumidifying, feeding & conveying, dosing & mixing, heating & cooling, granulating & recycling, automation solution, systematic solution, and hot runner system. Adhered to the management principle “focusing on a particular business, pursuing to be the world leader”, Shini people have created new situations one after another. Till now, Shini group has ranked among the world-class manufacturers of plastic auxiliary equipment and taken the lead of Asia's plastic auxiliary equipment industry.

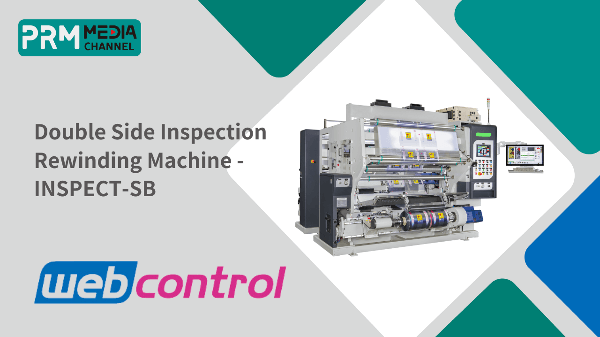

Inspection Rewinding Machine (INSPECT-SB) | WEBCONTROL

The double side inspection rewinding machine is designed print roll inspection. This model is able to inspect both sides of the material simultaneously to ensure the best quality in the minimum time.

Slitting Machine SLIT-HSI 1600 | WEBCONTROL

Inspection Rewinding Machine-Inspection Machine-I1-Inspect J300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Inspection Rewinding Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Inspection Rewinding Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Inspection Rewinding Machine service ensure our worldwide customers must be satisfied.

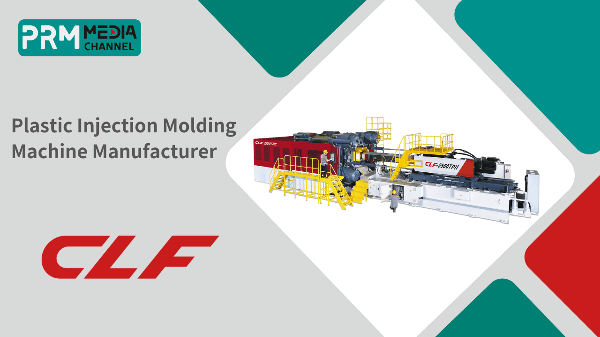

Injection Molding Solution | Plastic Injection Molding Machine Manufacturer | CLF

Chuan Lih Fa Injection Molding Machine at steady development of injection molding fields. With strict standards of the quality and the clamping force of the machines, combining high-tech European and Japanese microcomputer controllers, our electric injection molding machine adopts German Siemens controlling system as well as servo motors. The innovative structural design makes Chuan Lih Fa a leader in this industry.

Blown Film and Recycling Machines (Chinese Version)- POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, our PRM Director Alice will be carrying the interview with the CMO Mr. David Lo. During the interview, Mr. David Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

2024 TaipeiPlas International Plastics & Rubber Industry Show| CHUAN LIH FA

At the TaipeiPlas, PRM-Taiwan interviews CHUAN LIH FA MACHINERY WORKS CO., LTD. In this exclusive feature, CHUAN LIH FA demonstrates their latest custom-designed injection molding machines, highlighting innovations that push the boundaries of technology in the plastic injection molding industry. In this video, you'll learn how their new machines offer significant space-saving designs, as well as the ability to handle multi-color production, making them a versatile solution for manufacturers. Discover how CHUAN LIH FA is not only advancing technology but also fostering talent and driving progress in this dynamic industry.

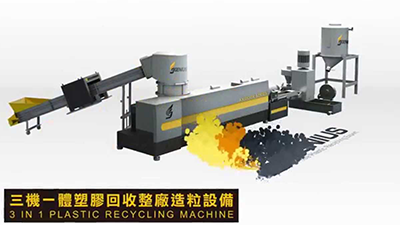

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature: -Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation. -Low power consumption, high output. Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space. Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

Find Your Plastic & Rubber Supplier | PRM-TAIWAN

Welcome to PRM-TAIWAN Plastic & Rubber B2B Website introduction video. In this video you will watch how to find Taiwanese Plastic and Rubber Machinery suppliers through PRM-Taiwan. It's so simple! Just go to www.prm-taiwan.com select the machinery or materials, and send your inquiry. Leave the rest part to us.

2024 CHINAPLAS Interview | ETERLONG

We are here with Melody from Eterlong Co., Ltd at the CHINAPLAS. ETERLONG is known for high-quality products, such as blown film machines, extrusion die and extruder filters, and their post-sale service. We gained information about how ETERLONG applies digitalization to their equipment.

Die Cutting Machine Manufacturer | Yicheen

Yicheen High Precision Die Cutting Machine offers a variety of options, such as CCD Auto Positioning, Auto movable Stacking, etc., click the link to see more Die Cutting Machine info: ???? https://bit.ly/3qbjbtf

Extrusion Blow Moulding Machine |FONG KEE

Extrusion Blow Moulding Machine - High Speed Blow Moulding Machine-hbb-ssg-Fong Kee Specializes in Extrusion Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Extrusion Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Extrusion Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

Upstream and Midstream of Taiwan Automation Manufacturing | What To Say EP16

Have you ever wondered why Taiwan is an automation and automotive parts manufacturing stronghold? In this episode, you will be explaining the first two streams, which are upstream and midstream, which are the initial points for the following procedure of the automotive industry.

TAIPEIPACK 2023 On-site Tour| PRM-TAIWAN

TAIPEIPACK 2023 exhibition tour is coming! Follow Daniel to learn about Taiwanese packaging manufacturers And the first-hand industry information!

Two Platen Plastic Injection Molding Machine | CLF

Two Platen Plastic Injection Molding Machine - Chuan Lih Fa CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.