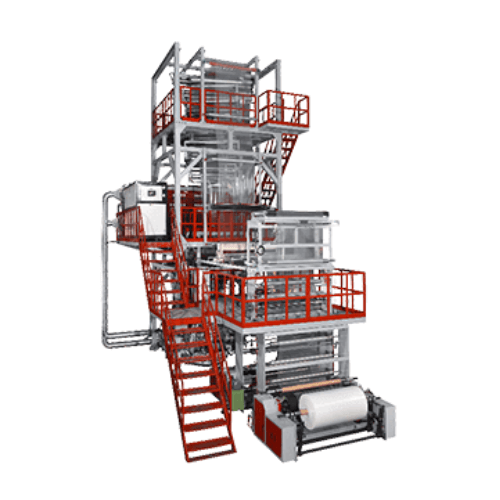

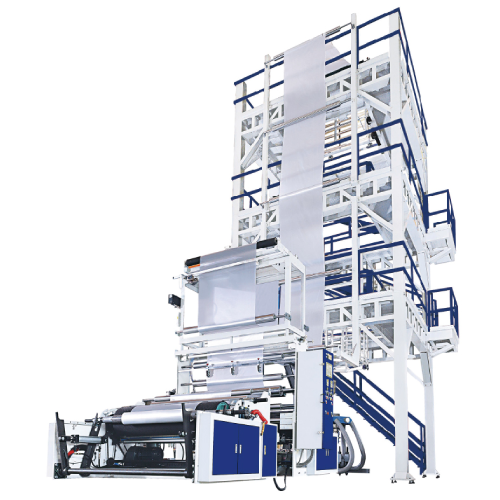

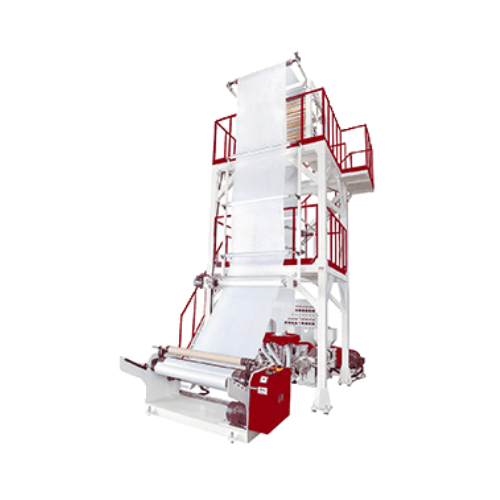

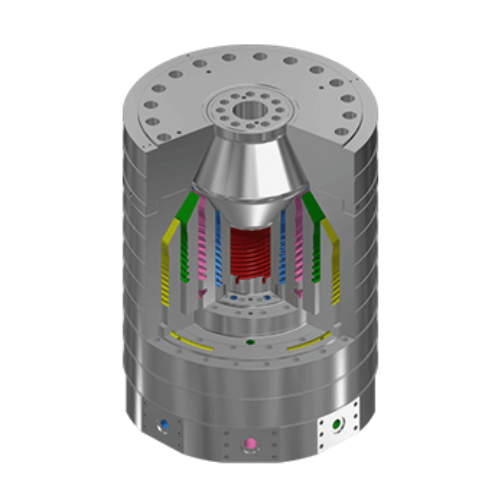

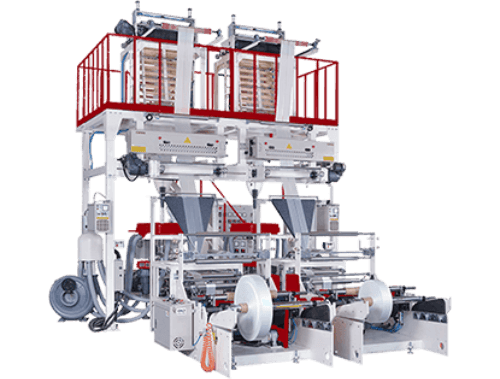

Relying on the many years manufacturing experience of extrusion products, we understand the principle of each process of plastic blown film extrusion, we have the manufacturing capacity of blown film production line. Besides, HSIN LONG’s Plastic Film Blowing Machine is customized which depends on characteristics of raw materials and final applications. Before designing the products, HSIN LONG emphasizes on communications and discussion with customers in order to build the reliance with customers. Depending on the use of material, we offer from 3 layers up to 5 layers co-extrusion plastic film blowing machine. Also, the final products have all the desired properties at a significantly reduced cost.

The main production process of plastic film blowing machines is to turn the polymer material into plastic films. Putting the raw material in the hopper of the blown film extruder at first. By the transportation of screws, material will be melted and become molten. Passing flow to the filter where to remove the impurities out and keep the material clear for the next blowing process. The material forms as a bubble tube from the extruder die head and is pulled up and flattened by the take-up unit. Following the winding paths, the plastic film winds as a complete roll which is the final process of plastic film production. This is the basic production process of plastic film blowing machines to produce films. Further, depending on the use of plastic film, the choice of plastic film blowing machine types will be totally different.

- Reduce the extra cost and increase the economic benefits

As for different industry, the application of plastic film covers a wide range which depends on the requirements of customers which including people’s livelihood products, medical supplies, agriculture film, and even biodegradable use. The various products application offer customers diverse choice to satisfy their demands.

- Packaging Film

- Barrier Film for food packaging

- Technical Film for high-tech applications

- Sealing Film

- Agricultural Film

- Medical Film

- Shrink and Stretch Film

- TPU Film