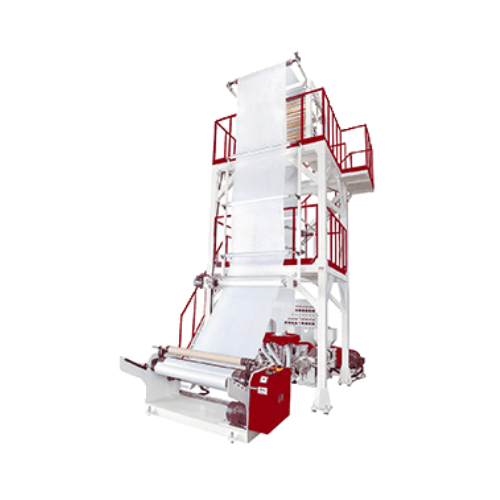

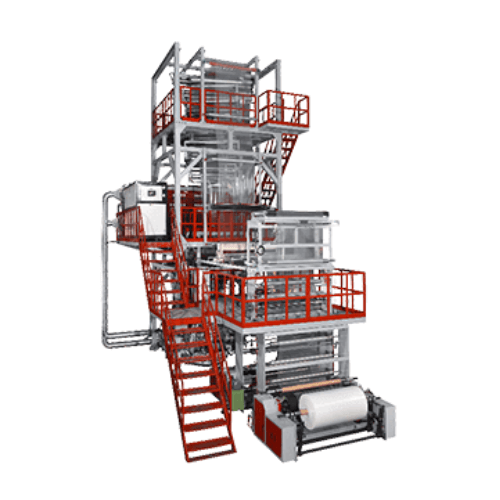

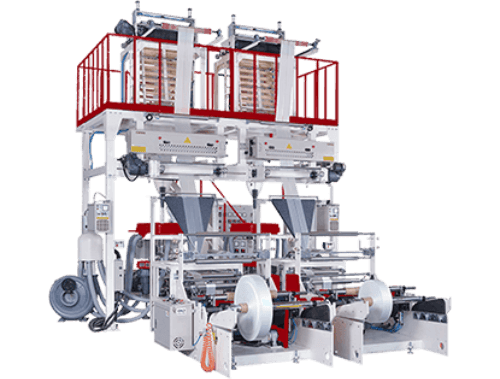

Offering a wide range of Plastic Film Blowing Machines and its related components which are available to all the countries is what HSIN LONG keeps working on. For Three Layers ABA Co-Extrusion Blown Film Machine which characteristic is focus on its well performance and changing speed of the materials is extremely fast. It saves more time for customers to change the material and shorten the labor time. Further, It lowers the material change time and reduces the material wastage as well which is the biggest advantages of this type of plastic film blowing machine.

The main production process of plastic film blowing machines is to turn the polymer material into plastic films. Putting the raw material in the hopper of the blown film extruder at first. By the transportation of screws, material will be melted and become molten. Passing flow to the filter where to remove the impurities out and keep the material clear for the next blowing process. The material forms as a bubble tube from the extruder die head and is pulled up and flattened by the take-up unit. Following the winding paths, the plastic film winds as a complete roll which is the final process of plastic film production. This is the basic production process of plastic film blowing machines to produce films. Further, depending on the use of plastic film, the choice of plastic film blowing machine types will be totally different.

Головки HSIN-LONG в основном используются для производства пленок для пищевой, строительной, сельскохозяйственной и медицинской продукции, в основном на экспорт. На данный момент мы занимаемся исследованиями и разработками и производством экструзионных машин, систем и штампов для производства высококачественных пленок с высокой добавленной стоимостью для текстильной, 4C, оптической промышленности и новых мобильных источников питания.

Пленка для упаковки пищевых продуктов

Сельскохозяйственная пленка

Медицинский фильм

- Fast material change

- Material cost reduction

- Customized services for blown film machine with different film width

Model |

HL65W1200 |

HL55W1000 |

HL45W650 |

| a) Material To Be Used: | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE |

| b) Layflat Film Width: | MAX:1100 | MAX:900 | MAX:550 |

| c) Extrusion Output: | MAX:120~140Kg/Hr | MAX:60~80Kg/Hr | MAX:38~45Kg/Hr |

| d) Film Thickness: | HDPE: 0.015mm~0.15mm LDPE: 0.02-0.2mm |

HDPE: 0.015mm~0.15mm LDPE: 0.02-0.2mm |

HDPE: 0.015mm~0.15mm LDPE: 0.02-0.2mm |

EXTRUDER |

|||

| a) Screw Dia.: | 65mm, L/D=30:1 | 55mm, L/D=30:1 | 45mm, L/D=30:1 |

| b) Gear Box: | 50HP | 30HP | 20HP |

| c) Driving Motor: | 50HP | 30HP | 20HP |

| d) Air Cooling Fan: | 4pcs | 3pcs | 2pcs |

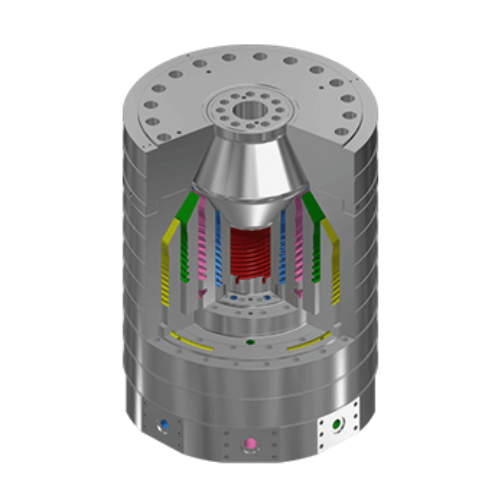

EXTRUSION DIE & COOLING EQUIPMENT |

|||

| a) Die Head: | HDPE150~180mm | HDPE90~120mm | HDPE50~80mm |

| c) Filter: | 65mm | 55mm | 45mm |

| d) Air Blower: | 7.5HP | 5HP | 3HP |

CONTROL PANEL |

|||

| a) Type: | Individual Box | Individual Box | Individual Box |

| b) Heating Zone: | 7 Heating Zone | 6 Heating Zone | 5 Heating Zone |

TAKE-UP UNIT |

|||

| a) Type: | Tower Fixed Type | Tower Fixed Type | Tower Fixed Type |

| b) Tower Height: | 6.5M | 5.5M | 3.5M |

| c) Take-Up Roller Width: | 1200mm | 1000mm | 650mm |

| d) Take-Up Motor: | 1HP + Inverter Control | 1HP + Inverter Control | 1/2HP + Inverter Control |

| f) Take-Up Plate: | Wood Type Aluminum Roller Type |

Wood Type Aluminum Roller Type |

Wood Type Aluminum Roller Type |

| g) Guide Roller: | 20kg/cm Torque Motor | 20kg/cm Torque Motor | X |

| h) Stabilizer: | M765 | M650 | M450 |

WINDING UNIT |

|||

| a) Type: | Single Station Manual Type | Single Station Manual Type | Single Station Manual Type |

| b) Working Method: | Surface Friction Type | Surface Friction Type | Surface Friction Type |

| c) Wound-Up Dia: | MAX. 800mm | MAX. 800mm | MAX. 800mm |

| d) Winding Motor: | A.C 1HP+TQ TQ Motor Control | 40kg/cm Torque Motor | 30kg/cm Torque Motor |

| e) Winding Shaft: | 2pcs | 2pcs | 2pcs |