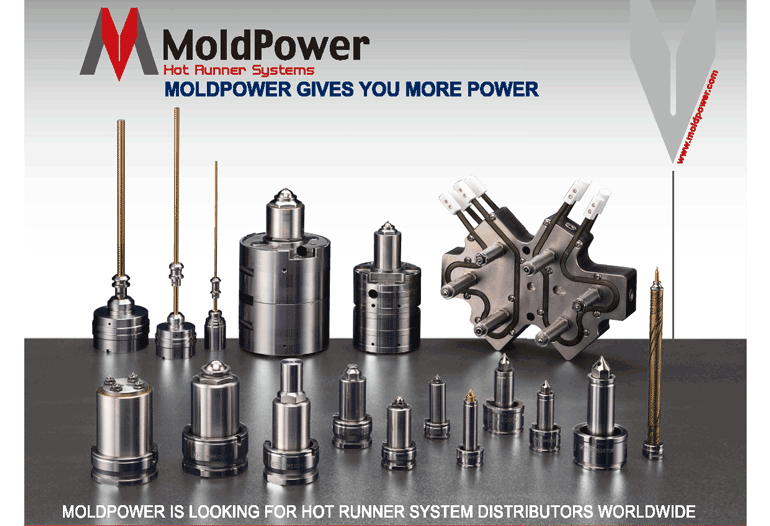

MOLDPOWER is Looking for Hot Runner System Distributors Worldwide

In 1997, Mr. Chen, Chung-Le and Mr. Chen, Ya-Mo co-founded Mold Power Co. Our core-values are honesty, quality, expertise, and a better future together. We are devoted to the design and the manufacturing of hot runner systems and originated the brand “Mold Power”. Because of our superior product performance, our products have been adopted by quite a few domestic mold plants for appliances, food containers, cosmetics, automotive parts, medical supplies, electronic products etc.. We provide customers with complete products and technology sharing.

MoldPower's Vision:

Trust - Trust and honest are the very first priorities of MoldPower's Visions. This is also the reason why MoldPower became a reliable partner.

Quality - Quality talks. It's also a truth that quality defines product value. Professionalism – while knowledge helps us stand out, professionalism helps us take the lead.

Sharing - The key to a fruitful future is to share knowledge with our customers, to share techniques with our partners, and to share the achievement with our employees.

Creativity, Pride.

MoldPower regards R&D and technical innovation crucial; our successful results speak for themselves:

• MPT temperature controller for multi-protection function

• TS-1 / TS-4 dual-purpose sequential controller

Our R&D, Our Service.

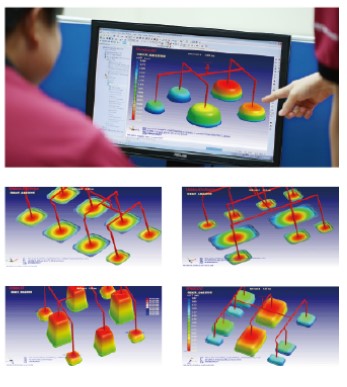

R&D and innovation are why MoldPower is a leader in this industry, while our personnel are the key to our continual innovation. Our expertise and reliability are a result of extensive use of advanced mold flow analysis and 3D drafting software in the mold and injection molding area.

Our Superiority

Technology, Stability.

With an increasing demand for precise molds for optoelectronics, electronics, and optics, uneven issues have occurred during the production procedure due to unequal temperature conduction.

In order to deal with this dilemma and to achieve real quality stability, MoldPower has developed Hot Runner Melt-Rotate Regulator Technology. This technology, in conjunction with injection simulation analysis has resolved the unequal temperature issue.

Our Quality, Our Equipment.

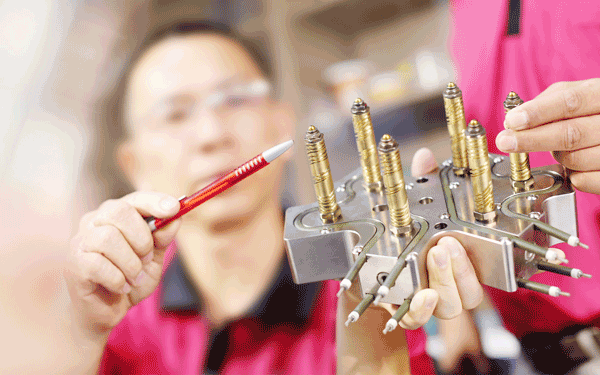

Hot runner mold design often encounters issues such as liquidity imbalance, uneven heating and plastic pyrolysis. These issues severely impact product quality. Therefore, mold temperature control systems are extremely important, and how to maintain an even material melting temperature is the key!

We manufacture our products with strict monitoring on all production stages from the raw materials to final product testing. We have adopted an advanced runner polishing machine, CNC engraving machine, bore polishing and grinding machines, and EDM machines. Furthermore, our product precision meets EU and US standards. We help our customers create higher-quality product design and mold making.

Global Sales Network

- Taiwan Headquarter

- China Branch (Dongguan)

- Vietnam Branch (Binh Duong Factory)

- Taiwan (Taipei、Taichung)

- China (Kunshan)

- Vietnam (Hanoi)

- Indonesia (Surabaya、Jakarta)

- Malaysia (Ipoh、Penang、Bandaraya Johor Bahru、Kuala Lumpur)

- India (New Delhi)

- Thailand (Bangkok)

E-News Categories

Экструдеры и экструзионные линии

- Экструзионная линия для пневматической пузырьковой пленки

- Экструзионная линия для пневматической пузырьковой пленки

- Линия для совместной экструзии с воздушным пузырьком

- Машины для изготовления пакетов

- Машина для производства пенопласта

- Выдувание пленки

- Машина для производства выдувных пленок

- Литьевая машина

- Покрывающая машина

- Экструзионная линия для пенопласта EPS / EPE

- Экструдер

- Ламинирующие машины

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Экструзионная техника для моноволокна

- Экструзионная линия для моноволокна

- PET Strapping Band Extrusion Lines

- Машины для изготовления пластиковых пакетов

- Совместная экструзия пластмассовой пленки

- Машины для производства пластиковых труб

- Машина для изготовления пластиковых труб

- Машина для производства ПВХ-шлангов

- Машины для производства соломы

- Двухшнековый экструдер

- Двухшнековые экструдеры

- Машина для производства тканого мешка

Перерабатывающее оборудование для предварительной обработки

- Линия для мытья бутылок

- Дробилка

- гранулятор

- гранулятор

- Грануляторы

- Pelletizing Machines

- Линия рециркуляции ПЭТ-бутылок

- Плита горячего мытья

- Машина для гранулирования

- Оборудование для переработки пластмасс для предварительной обработки

- Машины для переработки пластика

- Машина для переработки пластиковых отходов

- Перерабатывающие линии

- Машина для переработки отходов

- бумагорезка

- соковыжималки

- Бельевая веревка

- Оборудование для переработки отходов