SHINI: The Case of Central Mat. Processing System in Hand Tool Industry

Recently, Shini successfully delivered a set of central material conveying systems to a global hand tools manufacturer, which is a well-known in industrial hand and power tools. It is dedicated to providing over all solutions to the integrated hardware tool, storage device , and security system for the market. Facing the difficulties during the novel coronavirus pandemic, Shini didn’t stop moving forward and always put the customer's demands in priority. Responding to the call of returning to work and production from the local government, Shini produced a set of the remarkable material processing system with high expectations and strict requirements of the customer.

One of the main features in the whole system is the material error-proofing function. Firstly, it includes the insertion error-proofing with the material distribution station. Secondly, a bar code system with a material distribution station. Thus substantially eliminating human errors and improving the production reliability. Through smart detection means and program control, the insertion error-proofing unit can realize online material detection, so as to prevent human errors when selecting materials at the distribution station. By scanning, the barcode error-proofing unit will compare the default and current value. If the two values are the same, the green indicator will light on, which means the scanning is correct. Then, the storage hopper will be unlocked automatically to feed materials. Otherwise, the alarm will prompt code scanning error.

Using the remote monitoring system can further improve the system’s accessibility, and real-time data acquisition, statistics, and analysis will significantly improve the equipment’s management efficiency.

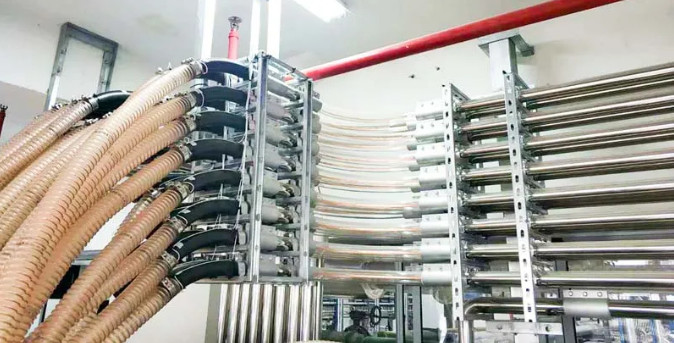

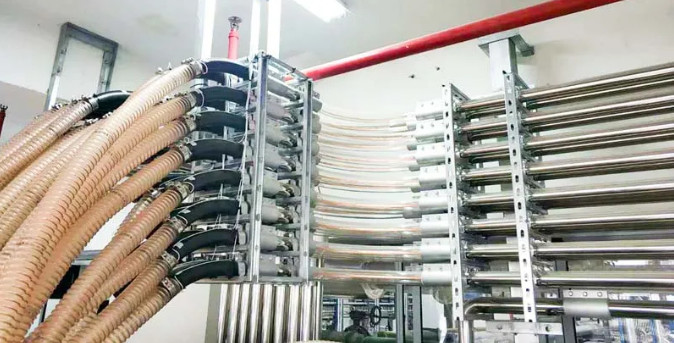

The whole system contains material storage, drying and conveying sections, and the stainless steel pipe and glass elbow assembly give reasonable and neatly-arranged layout, ideally improving the workshop’s space utilization and the working environment.

SHINI Official Website:

http://www.shini.com

SHINI at PRM-TAIWAN:

https://www.prm-taiwan.com/com/shini.html

One of the main features in the whole system is the material error-proofing function. Firstly, it includes the insertion error-proofing with the material distribution station. Secondly, a bar code system with a material distribution station. Thus substantially eliminating human errors and improving the production reliability. Through smart detection means and program control, the insertion error-proofing unit can realize online material detection, so as to prevent human errors when selecting materials at the distribution station. By scanning, the barcode error-proofing unit will compare the default and current value. If the two values are the same, the green indicator will light on, which means the scanning is correct. Then, the storage hopper will be unlocked automatically to feed materials. Otherwise, the alarm will prompt code scanning error.

Using the remote monitoring system can further improve the system’s accessibility, and real-time data acquisition, statistics, and analysis will significantly improve the equipment’s management efficiency.

The whole system contains material storage, drying and conveying sections, and the stainless steel pipe and glass elbow assembly give reasonable and neatly-arranged layout, ideally improving the workshop’s space utilization and the working environment.

SHINI Official Website:

http://www.shini.com

SHINI at PRM-TAIWAN:

https://www.prm-taiwan.com/com/shini.html

E-News Categories

Экструдеры и экструзионные линии

- Экструзионная линия для пневматической пузырьковой пленки

- Экструзионная линия для пневматической пузырьковой пленки

- Линия для совместной экструзии с воздушным пузырьком

- Машины для изготовления пакетов

- Машина для производства пенопласта

- Выдувание пленки

- Машина для производства выдувных пленок

- Литьевая машина

- Покрывающая машина

- Экструзионная линия для пенопласта EPS / EPE

- Экструдер

- Ламинирующие машины

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Экструзионная техника для моноволокна

- Экструзионная линия для моноволокна

- PET Strapping Band Extrusion Lines

- Машины для изготовления пластиковых пакетов

- Совместная экструзия пластмассовой пленки

- Машины для производства пластиковых труб

- Машина для изготовления пластиковых труб

- Машина для производства ПВХ-шлангов

- Машины для производства соломы

- Двухшнековый экструдер

- Двухшнековые экструдеры

- Машина для производства тканого мешка

Перерабатывающее оборудование для предварительной обработки

- Линия для мытья бутылок

- Дробилка

- гранулятор

- гранулятор

- Грануляторы

- Pelletizing Machines

- Линия рециркуляции ПЭТ-бутылок

- Плита горячего мытья

- Машина для гранулирования

- Оборудование для переработки пластмасс для предварительной обработки

- Машины для переработки пластика

- Машина для переработки пластиковых отходов

- Перерабатывающие линии

- Машина для переработки отходов

- бумагорезка

- соковыжималки

- Бельевая веревка

- Оборудование для переработки отходов