GENIUS: The Best Waste Film Recycling Solution to Reduce Carbon Footprint

The whole world has been paying attention to environmental protection issues and working on every detail in order to achieve it and contribute to our mother earth, especially after the outbreak of COVID-19. The plastics and rubber industry, which is closely related to our daily activities also pays more attention to this issue and implement practical measures for a better green future.

Plastic packaging consumption increased during the pandemic due to lockdowns in many countries. Especially the consumption of PE and PP type of plastic materials increases day by day. Research suggests that the recycling industry once again plays a crucial role to recycle and reuse plastic wastes in terms of environmental protection and decreasing carbon footprints. Such as in Europe, more than half of all goods are packaged with plastics. Only in 2018, the volume of plastic waste collected reached 29.1 million metric tons. To achieve reductions in greenhouse gases emission and land wastes, efficient recycling machines are a must in the industry.

GENIUS MACHINERY stands in the breach to fulfill its clients’ requirements with its more than 40 years of expertise. Especially for PE, PP, LDPE, and HDPE recycling solutions including plastic washing and drying plants, the company earned reputable fame in the market. Because of the recent increase in household plastic waste based on packaging material consumption, the needs of plastic recycling companies in film recycling lines and film washing lines are also increased. Now GENIUS is focusing on creating solutions in these fields to aid the decrease in carbon footprint, not only providing recycling machinery to its clients; but also providing less labor intensive, low energy consuming, and less maintenance-required machines.

GENIUS Film Washing and Drying Line: Prompt solution to Waste Plastic Film Recycling

Thanks to years of experience and reacting to market trends promptly, GENIUS is always a reliable plastic recycling machinery for its customers. GENIUS, once again, comes one step forward to provide turnkey solutions to the current demand in the market for waste film recycling and washing lines. The household films (industrial film, agricultural film) wastes must be washed and dried before the recycling process starts.

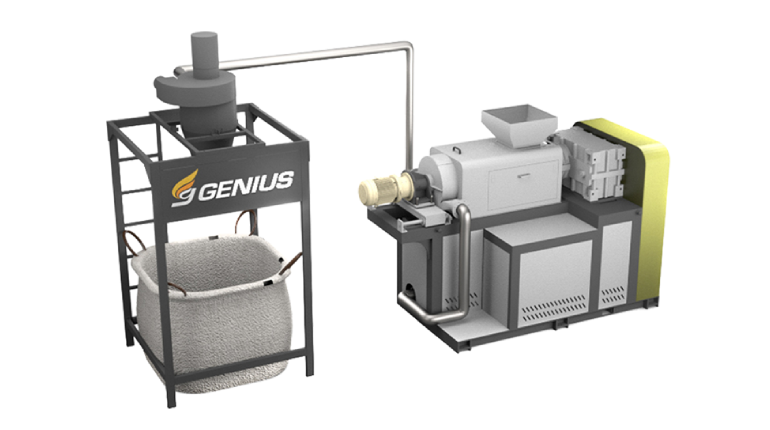

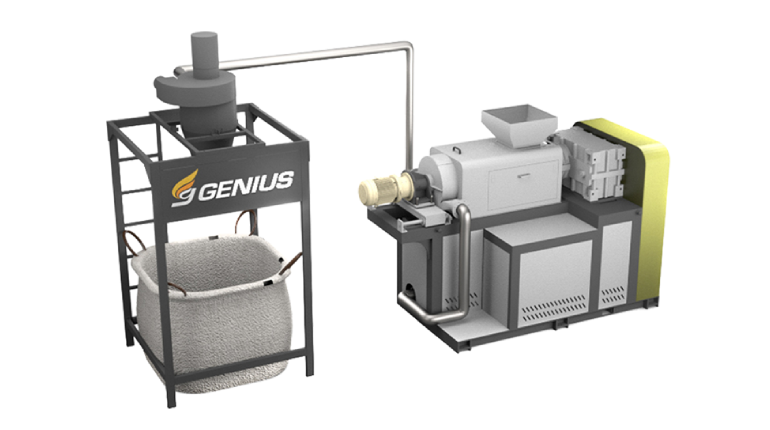

The GENIUS Film Washing Lines; which are equipped with crushing, washing, and drying units; bring solutions for the different levels of plastic films. The turnkey solutions allow plastic recyclers to process different dirt levels of materials from agriculture films, post-consumer films and bags, land-filled waste films to industrial stretch wrap films. After the washing step, the washed films are fed into a squeeze dryer to remove the moisture. Squeeze dryer is so crucial during plastic pelletization because moisture is one of the most important factors influencing the quality of plastic pellets and production efficiency when it comes to films. The final output of the squeeze dryers is high quality squeezed flakes with decreased moisture levels from 30% to 1%, whereas the traditional centrifugal dryers remain over 10-20% moisture level of outputs.

Customer Success Stories and After Sales Services

After pandemic, international buyers are more sensitive when they acquire machinery. The machine manufacturers who assure the solutions for their clients in terms of installation of the machinery, after sales services, part and maintenance supports come one step forward in the market. Through customized and durable machineries, GENIUS helps its customers to sustain a good reputation of quality in the industry, supports its clients through the help of local agents and the written and video instructions for installation and maintenance. At the end, with the fine plastic pellets outputs, customers assure stable business relationships with their clients.

GENIUS has been achieving many successful stories with its customers around the world. Such as in the USA a customer required a solution to recycle and reprocess post-agricultural wastes including LDPE and HDPE films. The customer also required a fine and high purity output to provide its Japanese client. GENIUS suggested to American customer a customized KRIEGER-125 series Cutter Compactor Plastic Recycling Machine for LDPE and HDPE Film Recycling.

In this case, machine is equipped with four sieves to achieve to decrease mesh size as maximum 150#. With the help of the latest pelletizing device and only 1 to 2 operator requirement, the customer received an up to 28% energy saving and 650kg/hr output machine for the highest purity plastic pellet outputs at an affordable cost.

On the other hand, a Taiwanese customer, who is Taiwan's biggest PE film recycler with a production capacity 2,000MT/Month, primarily ordered 2 sets of RECO-125i series Force Side Feeding Two Stage Plastic Recycling Machine for washed PE Films. Due to the high satisfaction, the customer ordered 2 more sets and decided to equip his second facility with the same machinery line.

The RECO-125i series recycling line provides for the customers the ability to operate the machine with only 1 to 2 operators to achieve up to 500 kg/hr of output. The connected main and sub extruders solve the overflow and leakage problems. Since no more excess gas emitted, there is no pollution created during the recycling process.

Ready to Meet Customers in K 2022

GENIUS always improves its technology and professional skills in order to provide the best solutions to customers. As one of the well-known plastic recycling machinery manufacturers, GENIUS can't wait to meet and interact with their valued customers in K 2022, the biggest exhibition of the industry in Germany this coming October.

Please do come visit GENIUS's stand if you are interested in latest plastic recycling machinery information.

GENIUS's stand no. in K 2022: Hall 12 / A02-10

Plastic packaging consumption increased during the pandemic due to lockdowns in many countries. Especially the consumption of PE and PP type of plastic materials increases day by day. Research suggests that the recycling industry once again plays a crucial role to recycle and reuse plastic wastes in terms of environmental protection and decreasing carbon footprints. Such as in Europe, more than half of all goods are packaged with plastics. Only in 2018, the volume of plastic waste collected reached 29.1 million metric tons. To achieve reductions in greenhouse gases emission and land wastes, efficient recycling machines are a must in the industry.

GENIUS MACHINERY stands in the breach to fulfill its clients’ requirements with its more than 40 years of expertise. Especially for PE, PP, LDPE, and HDPE recycling solutions including plastic washing and drying plants, the company earned reputable fame in the market. Because of the recent increase in household plastic waste based on packaging material consumption, the needs of plastic recycling companies in film recycling lines and film washing lines are also increased. Now GENIUS is focusing on creating solutions in these fields to aid the decrease in carbon footprint, not only providing recycling machinery to its clients; but also providing less labor intensive, low energy consuming, and less maintenance-required machines.

GENIUS Film Washing and Drying Line: Prompt solution to Waste Plastic Film Recycling

Thanks to years of experience and reacting to market trends promptly, GENIUS is always a reliable plastic recycling machinery for its customers. GENIUS, once again, comes one step forward to provide turnkey solutions to the current demand in the market for waste film recycling and washing lines. The household films (industrial film, agricultural film) wastes must be washed and dried before the recycling process starts.

The GENIUS Film Washing Lines; which are equipped with crushing, washing, and drying units; bring solutions for the different levels of plastic films. The turnkey solutions allow plastic recyclers to process different dirt levels of materials from agriculture films, post-consumer films and bags, land-filled waste films to industrial stretch wrap films. After the washing step, the washed films are fed into a squeeze dryer to remove the moisture. Squeeze dryer is so crucial during plastic pelletization because moisture is one of the most important factors influencing the quality of plastic pellets and production efficiency when it comes to films. The final output of the squeeze dryers is high quality squeezed flakes with decreased moisture levels from 30% to 1%, whereas the traditional centrifugal dryers remain over 10-20% moisture level of outputs.

Customer Success Stories and After Sales Services

After pandemic, international buyers are more sensitive when they acquire machinery. The machine manufacturers who assure the solutions for their clients in terms of installation of the machinery, after sales services, part and maintenance supports come one step forward in the market. Through customized and durable machineries, GENIUS helps its customers to sustain a good reputation of quality in the industry, supports its clients through the help of local agents and the written and video instructions for installation and maintenance. At the end, with the fine plastic pellets outputs, customers assure stable business relationships with their clients.

GENIUS has been achieving many successful stories with its customers around the world. Such as in the USA a customer required a solution to recycle and reprocess post-agricultural wastes including LDPE and HDPE films. The customer also required a fine and high purity output to provide its Japanese client. GENIUS suggested to American customer a customized KRIEGER-125 series Cutter Compactor Plastic Recycling Machine for LDPE and HDPE Film Recycling.

In this case, machine is equipped with four sieves to achieve to decrease mesh size as maximum 150#. With the help of the latest pelletizing device and only 1 to 2 operator requirement, the customer received an up to 28% energy saving and 650kg/hr output machine for the highest purity plastic pellet outputs at an affordable cost.

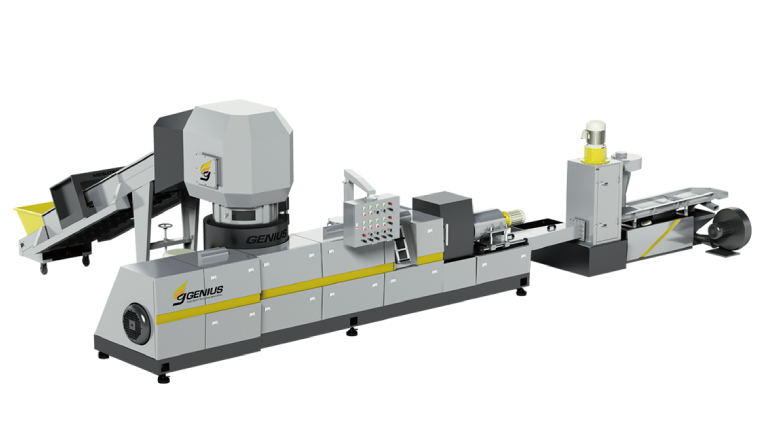

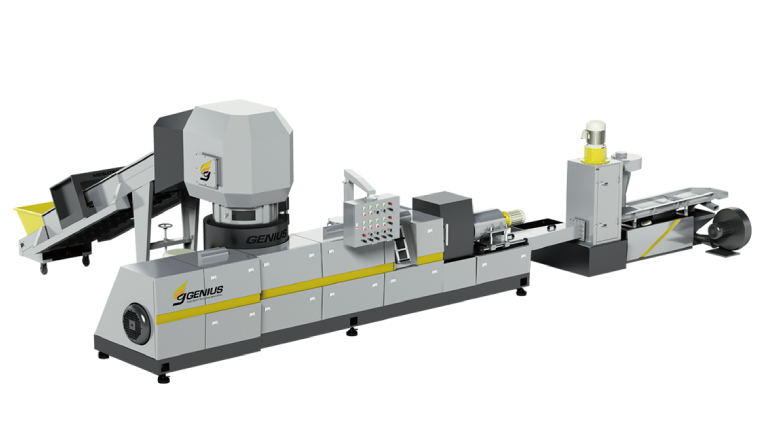

On the other hand, a Taiwanese customer, who is Taiwan's biggest PE film recycler with a production capacity 2,000MT/Month, primarily ordered 2 sets of RECO-125i series Force Side Feeding Two Stage Plastic Recycling Machine for washed PE Films. Due to the high satisfaction, the customer ordered 2 more sets and decided to equip his second facility with the same machinery line.

GENIUS: RECO-125i Series: 500 kg/hr Output

Ready to Meet Customers in K 2022

GENIUS always improves its technology and professional skills in order to provide the best solutions to customers. As one of the well-known plastic recycling machinery manufacturers, GENIUS can't wait to meet and interact with their valued customers in K 2022, the biggest exhibition of the industry in Germany this coming October.

Please do come visit GENIUS's stand if you are interested in latest plastic recycling machinery information.

GENIUS's stand no. in K 2022: Hall 12 / A02-10