How to Start Plastic Recycling Business? A Complete Guide to Choosing the Right Recycling Machine

Introduction

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, estimate start-up costs, obtain necessary financing, arrange for plastic transportation, and, most importantly, invest in a reliable plastic recycling machine.

Plastics are a diverse group of materials, and some plastics can be recycled by one type of process, while others require special processing. In order to figure out what types of plastic you will recycle, you first need to understand the different types of plastic that are available.

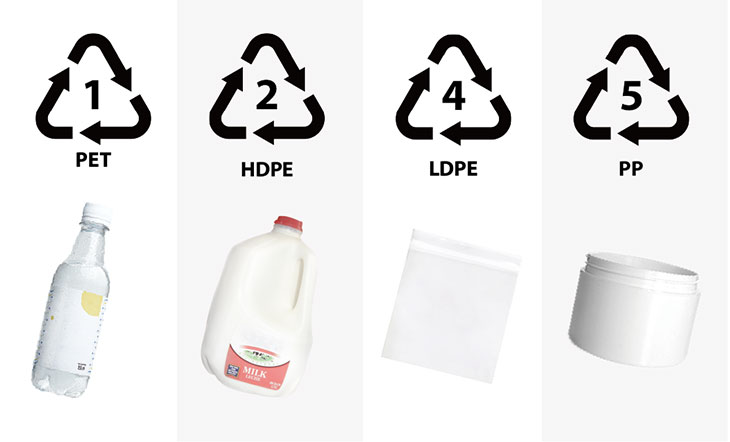

The most commonly recycled plastics

The most commonly recycled plastics are PET (Polyethylene terephthalate), HDPE (High-density polyethylene), LDPE (Low-density polyethylene), and PP (Polypropylene).

-

PET

PET is a popular plastic for water and soda bottles. It's also often used to make plastic bottles and containers. PET is a clear, tough, and transparent plastic that is resistant to damage and cracking.

-

HDPE

It is used to make plastic jugs, containers, and bottles that you might use for milk or juice. -

LDPE

It is used to make plastic films, packaging, and bags. -

PP

It is a versatile, lightweight, strong plastic that can be used in a variety of applications including packaging, containers, and bottles.

How to choose the recycling machine for different plastic materials?

For PET: Repro-PET recycling machine

This model is equipped with a strand-type pelletizing system, it is perfect for reprocessing plastic materials with high fluidity like PET. The air knives on this model make PET pellets with a uniform shape and high reusability rate.

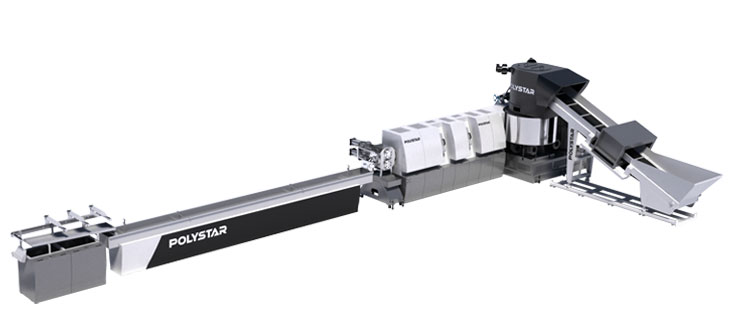

For HDPE, LDPE, PP films: Repro-Flex recycling machine

This model is equipped with a cutter-compactor, it is a great choice for processing HDPE, LDPE, and PP film materials. The recycling machine's cutter compactor prepares (pre-conditions) the plastic material for the extrusion process and feeds it directly into the extruder using centrifugal force.

For HDPE, LDPE, PP films with high printing areas: Repro-Flex Plus recycling machine

This model is integrated with a cutter compactor just like Repro-Flex. However, it has an additional extruder as well as three degassing zones and two filtration units. It is designed specifically for processing heavily printed plastic wastes, and it ensures minimal degradation of the material, resulting in uniform plastic pellets that may be reprocessed right into your production line.

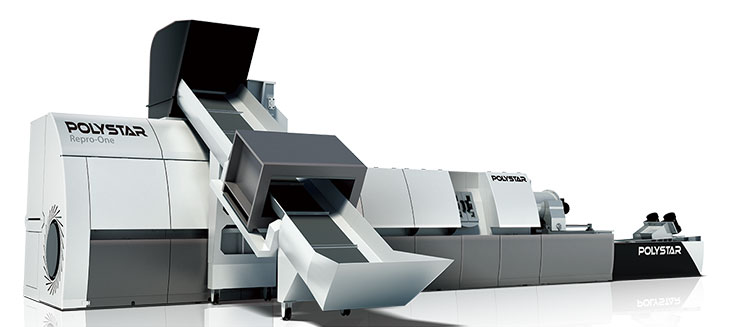

For PP raffia, woven, non-woven: Repro-One recycling machine

This model is equipped with a single shaft shredder, it is very effective when processing materials with higher strength such as PP raffia, woven and non-woven bags. It does not require a separate crusher, so you can recycle your plastic waste in one step.

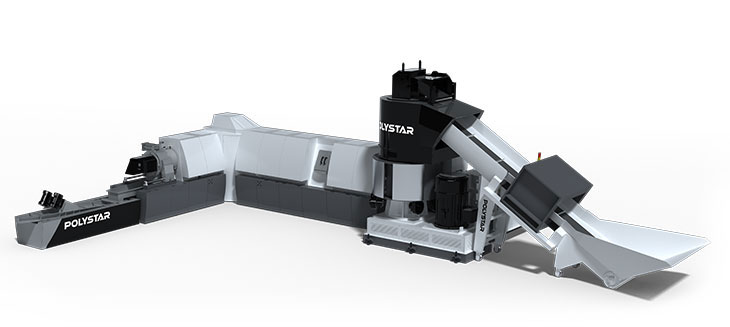

For PE, PP rigid regrinds: Repro-Direct recycling machine

This model does not have a compactor or shredder, you can feed the rigid regrinds directly into this machine through a hopper. This system ensures a faster and easier machine starting and stopping process compared to other plastic recycling systems.

For clean HDPE, LDPE films: Repro-Air recycling machine

This model is an air-cooled mini plastic recycling machine, which does not require huge space and budget for you to start recycling in your factory. It has a simple design that makes it very easy to operate. This mini plastic machine can be placed right next to your blown film machines or bag-making machines for you to recycle the waste right away.

Conclusion

Plastic recycling is a growing industry that can be profitable for businesses. As with any business venture, the first step is to determine what type of plastic you can recycle, and which machine is suitable for reprocessing your plastic materials. POLYSTAR has 34 years of experience in plastic recycling, we design several different models to deal with all kinds of plastic materials. Feel free to contact us if you are interested in starting your plastic recycling business.

Learn More

Экструдеры и экструзионные линии

- Экструзионная линия для пневматической пузырьковой пленки

- Экструзионная линия для пневматической пузырьковой пленки

- Линия для совместной экструзии с воздушным пузырьком

- Машины для изготовления пакетов

- Машина для производства пенопласта

- Выдувание пленки

- Машина для производства выдувных пленок

- Литьевая машина

- Покрывающая машина

- Экструзионная линия для пенопласта EPS / EPE

- Экструдер

- Ламинирующие машины

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Экструзионная техника для моноволокна

- Экструзионная линия для моноволокна

- PET Strapping Band Extrusion Lines

- Машины для изготовления пластиковых пакетов

- Совместная экструзия пластмассовой пленки

- Машины для производства пластиковых труб

- Машина для изготовления пластиковых труб

- Машина для производства ПВХ-шлангов

- Машины для производства соломы

- Двухшнековый экструдер

- Двухшнековые экструдеры

- Машина для производства тканого мешка

Перерабатывающее оборудование для предварительной обработки

- Линия для мытья бутылок

- Дробилка

- гранулятор

- гранулятор

- Грануляторы

- Pelletizing Machines

- Линия рециркуляции ПЭТ-бутылок

- Плита горячего мытья

- Машина для гранулирования

- Оборудование для переработки пластмасс для предварительной обработки

- Машины для переработки пластика

- Машина для переработки пластиковых отходов

- Перерабатывающие линии

- Машина для переработки отходов

- бумагорезка

- соковыжималки

- Бельевая веревка

- Оборудование для переработки отходов