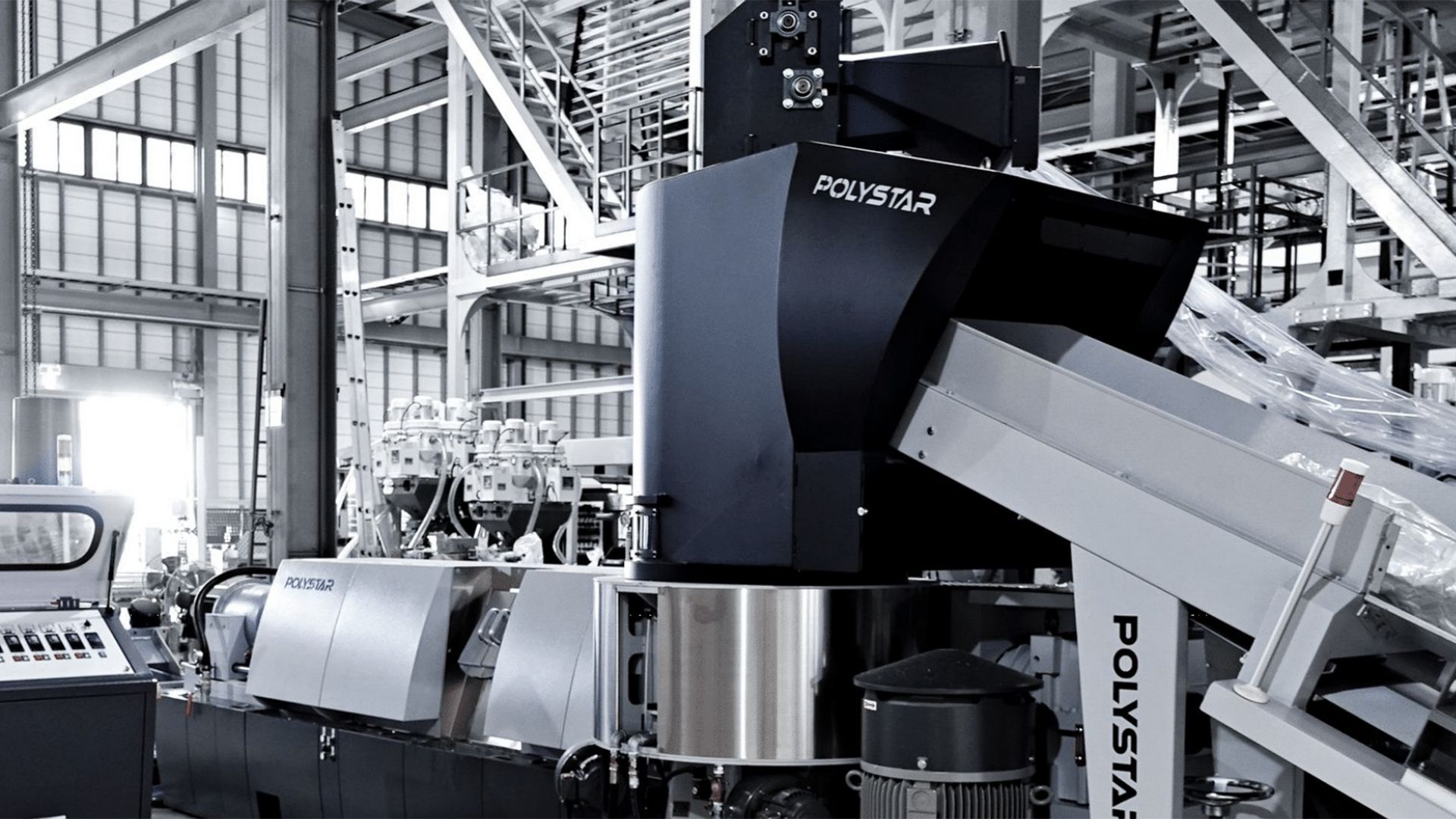

How to Boost Your Plastic Business Sustainability with POLYSTAR Recycling Machines?

Operating in the plastic industry requires consciousness of sustainability today; economic sustainability for businesses, and environmental sustainability to preserve the globe. Did you know you can achieve both of them and carry your business to a green future by investing in a plastic recycling machine? Whether you are a professional recycler or plastic manufacturer, the simple design and user-friendliness of POLYSTAR recycling machines will help you go green and save costs.

Environmental sustainability through plastic recycling

Waste reduction is one of the biggest advantages of plastic recycling machines. They enable you to convert plastic production wastes into reusable recycled materials while reducing the amount of plastic ending up in landfills or oceans.

Recycling plastic production scraps and reusing them for production again obviously help conserve these valuable products. Recycling plastic also requires lower energy consumption and creates a lower carbon footprint compared to producing virgin polymers.

( Plastic recycling machines help plastic producers save material and cost )

Economic sustainability of the businesses with plastic recycling machines

Using recycled plastic in production is more cost effective than using 100% virgin plastic. Having a plastic recycling machine in the production factory enables the business to actively participate in the circular economy, where plastic products are recycled and reused.

In addition to minimizing waste and maximizing resource efficiency, investing in plastic recycling machines can differentiate a business from competitors by reducing costs, increasing reputation, and complying with regulations and policies for waste management.

Which recycling machine can carry your business to a green future while saving costs?

Scrap plastic materials can be in many different shapes and polymer types. POLYSTAR designs compact and energy-saving plastic recycling machines for the versatile requirements of recyclers and plastic manufacturers whether they are small-sized or large-sized businesses.

1. Cutter compactor integrated for film and bags

Cutter compactor integration of Repro-Flex allows you to directly recycle PE and PP film and bag scraps without pre-cutting them. Besides, the two-stage recycling machine Repro-Flex Plus is a perfect choice for processing post-consumer, heavily printed, and laminated materials.

2. Shredder Integrated for raffia/woven and uncrushed plastic

Single shaft shredder integrated Repro-One, especially the favorite of PP raffia and woven bag producers. The integrated shredder is also powerful to process lumps, purging, and uncrushed hard plastics without overheating them.

3. Direct recycling solution for crushed regrind

If you already have crushed hard plastic regrind (PE, PP, ABS) and looking for a direct solution to recycle them into plastic pellets, the Repro-Direct regrind recycling machine is a perfect fit for you. This is the favorite machine for regrind recyclers, injection molding, blow molding, and plastic extrusion manufacturers.

4. Air Cooled machine for small-size plastic recycling

During the manufacturing of blown films and plastic bags, there are fixed scraps occur mostly caused by edge trims and cut-offs. If you have the small-size air-cooled recycling machine Repro-Air, then you can recycle and directly reuse the pellets from these PE plastic scraps in your production. The compact size of Repro-Air allows it to fit just near your blown film or bag-making machines.

Have you found a suitable plastic recycling machine above for your business? Do you need more information or further machine customization? Then, contact POLYSTAR today! Your sales specialist will assist you to choose an efficient plastic recycling machine for your plastic waste.

Learn more

Экструдеры и экструзионные линии

- Экструзионная линия для пневматической пузырьковой пленки

- Экструзионная линия для пневматической пузырьковой пленки

- Линия для совместной экструзии с воздушным пузырьком

- Машины для изготовления пакетов

- Машина для производства пенопласта

- Выдувание пленки

- Машина для производства выдувных пленок

- Литьевая машина

- Покрывающая машина

- Экструзионная линия для пенопласта EPS / EPE

- Экструдер

- Ламинирующие машины

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Экструзионная техника для моноволокна

- Экструзионная линия для моноволокна

- PET Strapping Band Extrusion Lines

- Машины для изготовления пластиковых пакетов

- Совместная экструзия пластмассовой пленки

- Машины для производства пластиковых труб

- Машина для изготовления пластиковых труб

- Машина для производства ПВХ-шлангов

- Машины для производства соломы

- Двухшнековый экструдер

- Двухшнековые экструдеры

- Машина для производства тканого мешка

Перерабатывающее оборудование для предварительной обработки

- Линия для мытья бутылок

- Дробилка

- гранулятор

- гранулятор

- Грануляторы

- Pelletizing Machines

- Линия рециркуляции ПЭТ-бутылок

- Плита горячего мытья

- Машина для гранулирования

- Оборудование для переработки пластмасс для предварительной обработки

- Машины для переработки пластика

- Машина для переработки пластиковых отходов

- Перерабатывающие линии

- Машина для переработки отходов

- бумагорезка

- соковыжималки

- Бельевая веревка

- Оборудование для переработки отходов