Advanced yet Easy-to-Use Blown Film Extrusion Technology – Key to Eco-friendly Packaging

Eco-friendly packaging is no longer just a trend but a necessity for both environmental and economic sustainability. Blown film extrusion, a key process in packaging film production, must continuously advance to meet the growing demands of the market.

Let’s explore how POLYSTAR is innovating its blown film extrusion technology to support the development of eco-friendly packaging solutions.

Stable operation saves material and reduces wastes

Whether monolayer extruders or co-extrusion machines, POLYSTAR blown film machines have gained the fame of stable operation among our customers in more than 110 countries. We witness our customers producing films for their specific product requirements smoothly due to the precision in the screw and die head designs; carefully testing parameters like temperature, heating/cooling rates, film width, thickness, and tension. This operation stability not only saves from defective scraps but also saves energy and labor hours.

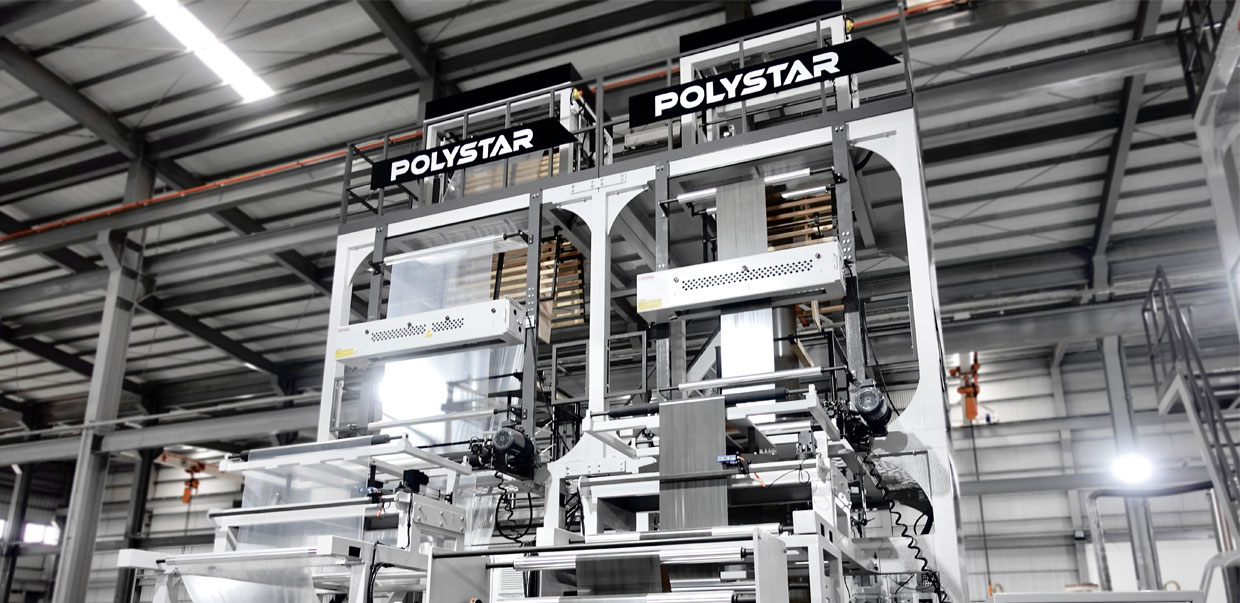

(POLYSTAR machines are strictly tested before shipping to customers)

Moreover, the simple design of the blown film extruders makes the production process easier for the operators. Hence, the operators can manage multiple POLYSTAR-blown film extruders simultaneously.

Material optimization keeps you sustainable and profitable

PE derivatives are often used in blown film extrusion. These materials are highly recyclable and producers often blend PE, HDPE, LDPE, and LLDPE with each other as well as with the bioplastics, CaCO3, recycled plastics, and color or filler masterbatches.

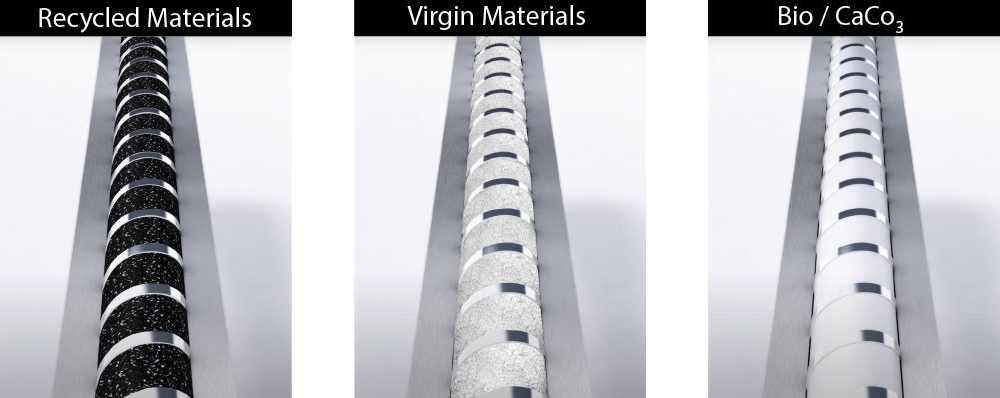

POLYSTAR designs its screws for excellent blending and melting performance for these various tasks of film producers. As a result, the producers will be more flexible to optimize the materials desired and use more recycled plastics, while they will be less dependent on virgin polymers.

( Optimal screw design for a variety of materials )

In terms of material saving and reducing carbon footprint, many POLYSTAR customers are upgrading their mono-layer blown film machines to ABA three layer blown film machines. The most prominent advantage of an ABA film extruder is the ability to use more recycled plastics and CaCO3 in the mid-layer (B) while having a smooth surface on the outer layers (A). Producers can manufacture more eco-friendly, 3-layer strong films with only two extruders.

( ABA extruder is an eco-blown film machine that allows more recycled material use )

Production flexibility with custom-made machines reduces carbon footprint

Before deciding to purchase a blown film machine, it can be advantageous for you to contact our sales specialists, to get suggestions on what types of machines are more feasible for your production. Because POLYSTAR focuses on highly customizable blown film extruders to save you energy, space, and material.

For instance, twin-head blown film extruders produce two different widths & thicknesses of film rolls at the same time on different winders, while using only one extruder. The optimal width interval of the machine allows it to cover most of the plastic bag applications in the market including t-shirt bags, garbage bags, flat shopping bags, bags on rolls, etc.

In conclusion, blown film extrusion machines are vital players in the production of eco-friendly packaging products. An advanced yet simple-designed blown film extruder can optimize the usage of plastic polymers, reduce waste, and conserves resource. Thus, it can minimize the environmental impact while maintaining productivity. This is the main philosophy of POLYSTAR while manufacturing its machines.

Learn more

Экструдеры и экструзионные линии

- Экструзионная линия для пневматической пузырьковой пленки

- Экструзионная линия для пневматической пузырьковой пленки

- Линия для совместной экструзии с воздушным пузырьком

- Машины для изготовления пакетов

- Машина для производства пенопласта

- Выдувание пленки

- Машина для производства выдувных пленок

- Литьевая машина

- Покрывающая машина

- Экструзионная линия для пенопласта EPS / EPE

- Экструдер

- Ламинирующие машины

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Экструзионная техника для моноволокна

- Экструзионная линия для моноволокна

- PET Strapping Band Extrusion Lines

- Машины для изготовления пластиковых пакетов

- Совместная экструзия пластмассовой пленки

- Машины для производства пластиковых труб

- Машина для изготовления пластиковых труб

- Машина для производства ПВХ-шлангов

- Машины для производства соломы

- Двухшнековый экструдер

- Двухшнековые экструдеры

- Машина для производства тканого мешка

Перерабатывающее оборудование для предварительной обработки

- Линия для мытья бутылок

- Дробилка

- гранулятор

- гранулятор

- Грануляторы

- Pelletizing Machines

- Линия рециркуляции ПЭТ-бутылок

- Плита горячего мытья

- Машина для гранулирования

- Оборудование для переработки пластмасс для предварительной обработки

- Машины для переработки пластика

- Машина для переработки пластиковых отходов

- Перерабатывающие линии

- Машина для переработки отходов

- бумагорезка

- соковыжималки

- Бельевая веревка

- Оборудование для переработки отходов