Double-Side Inspection and Precision Seaming: Unleashing INSPECT-SB and K2 Plus for Maximum Efficiency

Double Side Rewinder For High Quality Inspection – INSPECT-SB

Double side inspection rewinding machine is designed for flexible packaging application with fully inspection system. This model is able to inspect both sides of material simultaneously, to ensure the best quality in the minimum time. It is suitable for the use of cosmetic, medical and high-end products. Moreover, fully integrated system and user-friendly operation maximize the efficiency. INSPECT-SB is the choice for reaching highest productivity with best quality.

Features:

- Shaftless unwind and rewind

- Roll lift-in system

- reverse function

- Integration of 100% inspection camera

- Edge trim slitting

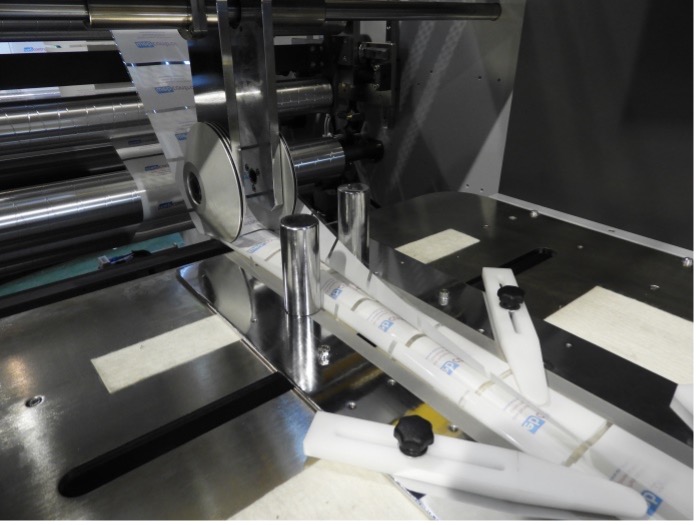

The Most Advanced Seaming Machine – K2 Plus

Webcontrol innovates the new generation of seaming machine, PLUS series, the most advanced seamer in the industry. This new design offers friendly operations, facilitating training with the most automated machine on the market.

K2 Plus is an entry model for shrink sleeve converting. Fastest set-up with the lowest waste is a great point for easy operation. The new layflat system will adjust automatically and accurately as operator sets the target width on HMI. Besides, no forming fingers eliminate friction inside the film. Furthermore, better tension control can seam as close as 5mm from the edge of the film to fit multiple types, from cap seal sleeves and full body sleeves, up to the fixed labeling in the middle body and the upper or lower overlapping sleeves.

Features:

- Fastest set-up in the industry

- Frictionless layflat system

- Three independent tension zones on unwind, forming and rewind.

- Automatic layflat correction

- Can seam as close as 5mm form the fold

With a lot of advantages, this new machine promises to revolutionize the way shrink sleeves are converted.

Read more:

Экструдеры и экструзионные линии

- Экструзионная линия для пневматической пузырьковой пленки

- Экструзионная линия для пневматической пузырьковой пленки

- Линия для совместной экструзии с воздушным пузырьком

- Машины для изготовления пакетов

- Машина для производства пенопласта

- Выдувание пленки

- Машина для производства выдувных пленок

- Литьевая машина

- Покрывающая машина

- Экструзионная линия для пенопласта EPS / EPE

- Экструдер

- Ламинирующие машины

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Экструзионная техника для моноволокна

- Экструзионная линия для моноволокна

- PET Strapping Band Extrusion Lines

- Машины для изготовления пластиковых пакетов

- Совместная экструзия пластмассовой пленки

- Машины для производства пластиковых труб

- Машина для изготовления пластиковых труб

- Машина для производства ПВХ-шлангов

- Машины для производства соломы

- Двухшнековый экструдер

- Двухшнековые экструдеры

- Машина для производства тканого мешка

Перерабатывающее оборудование для предварительной обработки

- Линия для мытья бутылок

- Дробилка

- гранулятор

- гранулятор

- Грануляторы

- Pelletizing Machines

- Линия рециркуляции ПЭТ-бутылок

- Плита горячего мытья

- Машина для гранулирования

- Оборудование для переработки пластмасс для предварительной обработки

- Машины для переработки пластика

- Машина для переработки пластиковых отходов

- Перерабатывающие линии

- Машина для переработки отходов

- бумагорезка

- соковыжималки

- Бельевая веревка

- Оборудование для переработки отходов