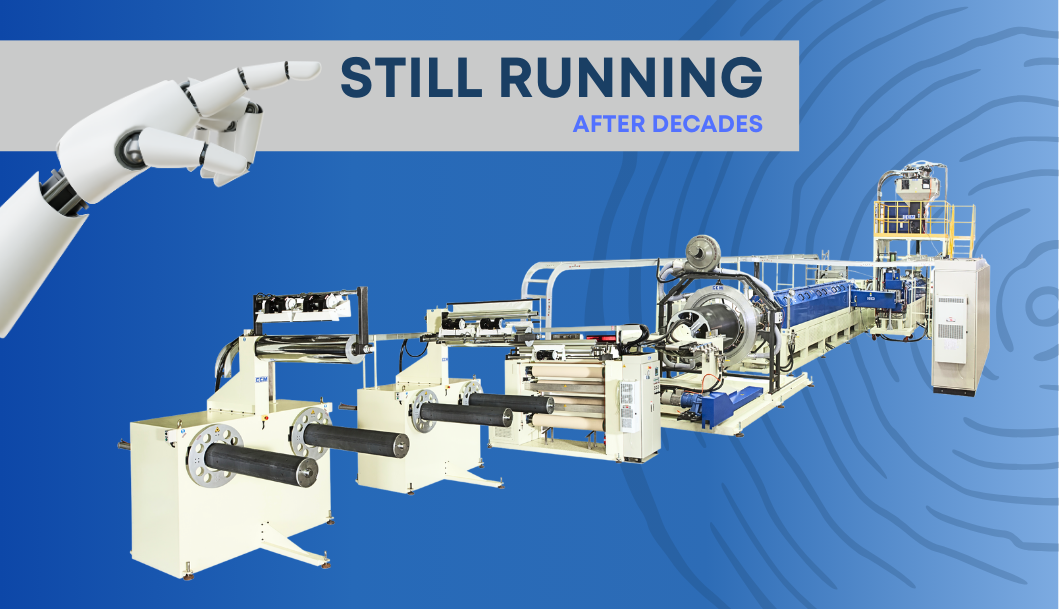

Still Running. Still Leading. Always Chi Chang.

Still Running After All These Years?

“I’ve been promoted twice since I joined this company… and we’re still using the same Chi Chang plastic sheet extrusion line.”

It may sound like a joke, but for many Chi Chang customers, this is simply their daily reality.

While most manufacturers replace sheet extrusion machines every 5 to 10 years, Chi Chang lines are still delivering consistent performance after three to four decades.

Why Chi Chang Plastic Sheet Extrusion Machines Last So Long

Long-Term Reliability That Pays Off

Across the globe—from Asia and Europe to the Americas and beyond—Chi Chang plastic sheet extrusion lines have proven to operate with minimal downtime and maintenance over decades. The result? Lower total cost of ownership and greater peace of mind.

Versatile Material Compatibility

Our machines are engineered to handle a wide range of materials—including PP, PS, PET, and PE—making them ideal for everything from food packaging to stationery production.

Precision That Doesn’t Fade

With high-performance T-die systems and three-roll calenders, Chi Chang sheet extrusion lines consistently deliver:

- Uniform sheet thickness

- High-speed output

- Smooth, high-quality surface finishes

Modular and Scalable to Your Needs

From single-layer to multilayer configurations (e.g., A-B-A), our systems are tailored to your specifications. We also support integration with gravimetric feeding, automatic stacking, and inline recycling.

Not Just Sheets—Also Leading in EPS Foam Sheet Extrusion

In addition to our flagship plastic sheet extrusion machines, Chi Chang has been developing high-performance EPS foam sheet extrusion systems since 1972.

The New Generation EPS Machine line covers:

- EPS output: 200–720 kg/hr

- EPE output: 120–500 kg/hr

- Widely used in the production of food trays, protective packaging, and more

These machines are available in multiple models to suit different capacity needs and are equipped with advanced components, such as:

- Automatic take-up and winding units

- Gear pump and continuous screen changer

- LEWA butane pump

- Air cooling ring and forming mandrel

All designed to ensure high efficiency, stable output, and excellent product consistency.

What Our Customers Are Saying

“The machine runs better than some of our newer ones.”

“We’ve only replaced a couple of parts in 30 years.”

“We budgeted for a new line… then realized we didn’t need one yet.”

These aren’t complaints—they’re proof of Chi Chang machines' lasting performance and reliability over time.

Consider Adding—Not Replacing

A reliable machine doesn't mean standing still. Our latest generation of plastic sheet extrusion machines and EPS lines includes:

- Smart control systems and automation

- Energy-efficient upgrades

- Easier maintenance and diagnostics

- Enhanced safety and operator ergonomics

Whether you're expanding capacity or entering new markets, we’re ready to support your long-term growth—today and in the decades to come.

Applications and Technical Features

Industries We Serve

- Packaging: Food trays, blister packs, foam containers

- Stationery: Folders, book covers

- Industrial: Divider sheets, protective liners

Technical Highlights

- Precision T-die systems for consistent thickness

- Three-roll calenders for surface smoothness

- EPS foam technology with output up to 720 kg/hr

- Multilayer configurations customized to your product needs

Trusted in Global Sheet Extrusion and EPS Since 1972

With more than 50 years in plastic sheet extrusion and a growing footprint in EPS foam sheet technology, Chi Chang continues to help customers deliver quality, durability, and high-value output.

Ready to Future-Proof Your Production?

Why settle for machines that last a few years when you can invest in a line that outlives your career?

With Chi Chang, you’re not just buying a machine—you’re building a legacy of performance, precision, and profit.

Let’s create a production line so reliable, you’ll forget what downtime even feels like.

Talk to us today, and take the first step toward the last extrusion line you’ll ever need.

Экструдеры и экструзионные линии

- Экструзионная линия для пневматической пузырьковой пленки

- Экструзионная линия для пневматической пузырьковой пленки

- Линия для совместной экструзии с воздушным пузырьком

- Машины для изготовления пакетов

- Машина для производства пенопласта

- Выдувание пленки

- Машина для производства выдувных пленок

- Литьевая машина

- Покрывающая машина

- Экструзионная линия для пенопласта EPS / EPE

- Экструдер

- Ламинирующие машины

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Экструзионная техника для моноволокна

- Экструзионная линия для моноволокна

- PET Strapping Band Extrusion Lines

- Машины для изготовления пластиковых пакетов

- Совместная экструзия пластмассовой пленки

- Машины для производства пластиковых труб

- Машина для изготовления пластиковых труб

- Машина для производства ПВХ-шлангов

- Машины для производства соломы

- Двухшнековый экструдер

- Двухшнековые экструдеры

- Машина для производства тканого мешка

Перерабатывающее оборудование для предварительной обработки

- Линия для мытья бутылок

- Дробилка

- гранулятор

- гранулятор

- Грануляторы

- Pelletizing Machines

- Линия рециркуляции ПЭТ-бутылок

- Плита горячего мытья

- Машина для гранулирования

- Оборудование для переработки пластмасс для предварительной обработки

- Машины для переработки пластика

- Машина для переработки пластиковых отходов

- Перерабатывающие линии

- Машина для переработки отходов

- бумагорезка

- соковыжималки

- Бельевая веревка

- Оборудование для переработки отходов