Driving a Sustainable Printing Future through Customization: Printplas Meets Evolving Global Industry Needs

As the global plastics and rubber industries embrace green transformation and smart manufacturing, printing equipment is no longer merely a final-stage processing tool—it has evolved into a critical node connecting the efficiency and sustainability of the entire packaging supply chain. Taiwan-based flexographic printing machine manufacturer, Printplas Machinery Co., Ltd., leverages over two decades of technical expertise and customization capabilities to confidently meet global demands for highly precise, efficient, and tailored printing solutions.

Every Machine is a Customized Solution

Printplas specializes in manufacturing CI (Central Impression) and STACK-type flexographic printing machines widely used in high-end printing on substrates including plastic films, paper, and eco-friendly materials. The company's internal engineering design team excels in comprehensive customization—from printing width, ink modules, and feeding systems to compatibility with environmentally friendly inks.

Global Success Stories Highlight Printplas’ Expertise:

-

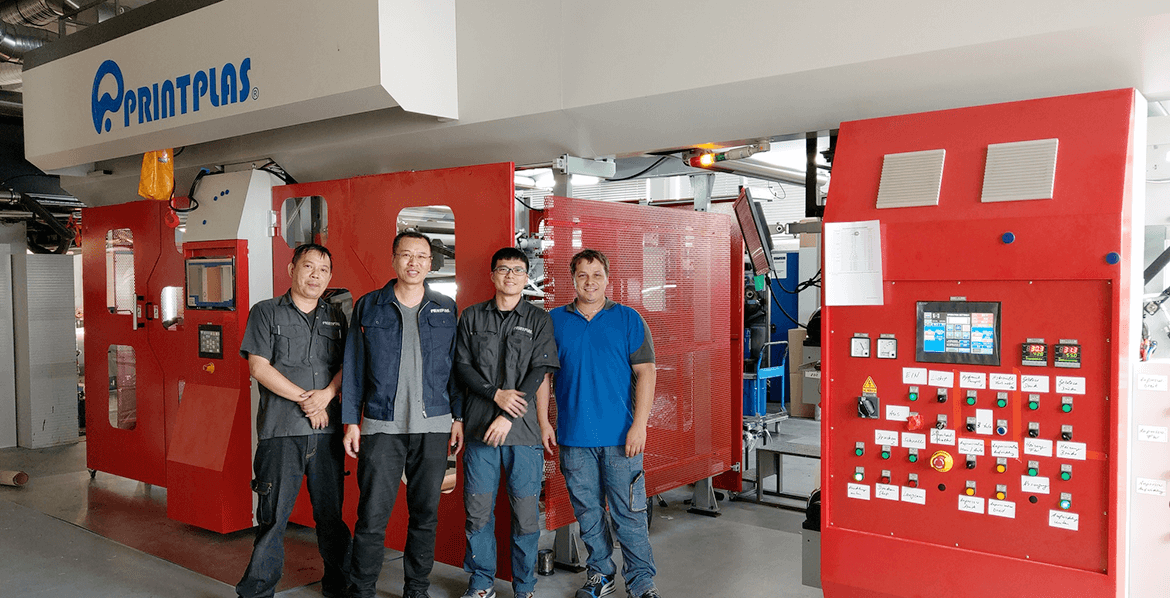

Russia | 2700mm Ultra-Wide Flexographic Printing Machine

Responding to a large Russian plastic processing company's needs, Printplas designed and built its largest-ever flexographic printer with a 2700mm ultra-wide configuration. Equipped with high-precision synchronization control and enhanced tension systems, this machine effectively solved stability issues inherent in printing large-sized materials, demonstrating Taiwan's advanced capability in heavy-duty equipment design.

-

Peru & Mexico | PKF 1400-4HS Four-Color High-Speed Paper Printing Machines

Branch offices of a major Latin American group located in Peru and Mexico chose Printplas for upgrading their color paper bag printing processes. Supporting paper weights ranging from 60 to 350 gsm, these machines operate reliably, boosting productivity and ensuring consistent brand visual quality across both locations.

-

Germany | STACK-Type Multifunctional Printing Machine Technical Support Collaboration

Printplas collaborated with a German technical team to accommodate special substrates like high-temperature resistant and easy-tear films. Providing structural design recommendations and tension control solutions, Printplas secured technical approval and established foundations for long-term cooperation.

These cases clearly show not only Printplas’ technical prowess but also its nuanced understanding and agile responsiveness to diverse market needs and product specifications.

Company Culture: Machinery Design Rooted in Customer Needs and Understanding

Printplas emphasizes "co-design with customers," embedding problem-solving missions into every machine from initial discussions. Whether applications involve food packaging, stationery, shopping bags, or industrial packaging, Printplas utilizes technical interviews and meticulous planning to craft printing equipment precisely aligned with customer requirements and operational preferences.

This responsive and collaborative culture has secured enduring partnerships with buyers across Central and South America, Europe, Canada, and the Middle East, explaining why more global clients increasingly choose deep collaboration with Taiwanese manufacturers over standard purchases.

Aligned with Trends and Technology: Supporting Global Sustainable Manufacturing

With global industries aiming for carbon reduction and smart manufacturing—such as lowering carbon footprints, using biodegradable materials, and adopting digital monitoring—Printplas has proactively adapted its designs:

-

Energy-Efficient Servo Drives:

Precise control and lower energy consumption

-

Multi-Stage Drying Modules with Adjustable Airflow:

Adaptable drying solutions for various inks and substrates

-

Water-Based Ink Compatibility:

Reduced volatile organic compound emissions

-

IoT Upgrade Capability:

Remote support to quickly fix issues and reduce downtime

Continually Evolving as a Printing Solutions Expert

Exhibitions offer temporary visibility, but technology and reliability build a lasting competitive advantage. Printplas embodies Taiwan’s machinery industry's dedication to deep customer engagement, effective communication, and ongoing innovation. Even without physical exhibition attendance, Printplas continues to shine globally through proven track records and customized solutions.

Additionally, leveraging PRM's O2O international exhibition marketing program, Printplas achieves simultaneous online exposure and media presence during major events like the K Fair. This approach ensures global buyers gain comprehensive insights into Printplas’ technological highlights and practical applications, even remotely.

From concept to delivery, Printplas ensures every printing machine is a key factor for production line upgrades, maintaining its pivotal role in the global packaging market.

Founded in 2001, Printplas Machinery Co., Ltd. specializes in the design and manufacture of CI and flexographic printing machines. Their solutions are widely applied to high-end printing on substrates such as paper, plastic films, and eco-friendly materials. With strong mechanical engineering capabilities and global customization experience, Printplas is committed to delivering high-efficiency, energy-saving, and environmentally conscious printing systems to packaging customers worldwide. The company values close communication and co-development with clients. Its machines have been successfully deployed across Europe, Latin America, the Middle East, and Southeast Asia, consistently showcasing the strength and reliability of “Made in Taiwan” on the global stage.